- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Common Applications of ASTM A105 Steel Flanges

Jan 9 2026

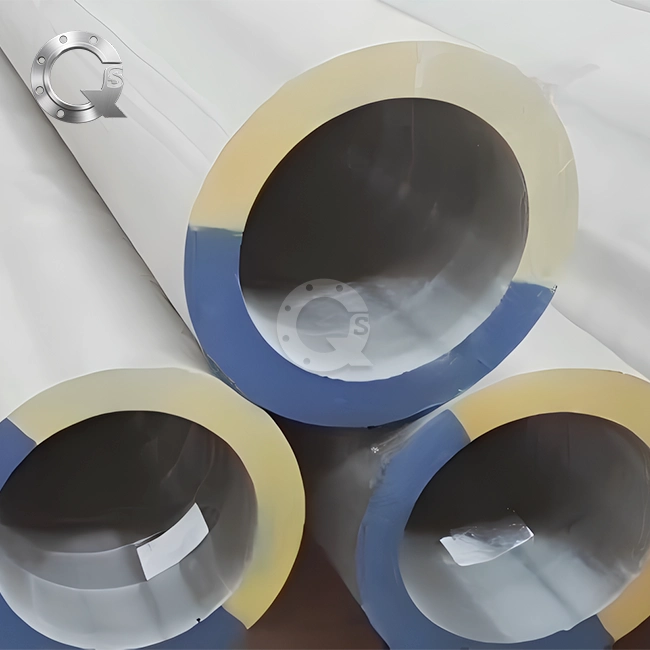

ASTM A105 steel flanges are very important parts of high-pressure pipe systems in many different types of businesses because they are very reliable and work very well. Forged carbon steel flanges like these work great in oil and gas, petroleum processing, power generation, water treatment plants, and naval settings. The strong features of A105 carbon steel make these flanges perfect for connecting pipes, pressure tanks, and other machinery in tough industrial settings where temperature and pressure changes are typical problems.

Understanding ASTM A105 Steel Flanges: Specifications and Standards

Carbon steel flanges made from ASTM A105 material are the best way to connect pipes in industry. These cast parts have great mechanical qualities and have been shown to be reliable, so big businesses all over the world can't do without them.

Chemical Composition and Material Properties

Because of its chemical makeup, A105 carbon steel makes a stable base for commercial uses. The highest amount of carbon is usually around 0.35%, and the highest amount of manganese is between 0.60% and 1.05%. Manganese gives the material its important mechanical power. Silicon content stays below 0.35%, which helps the material be easy to work with during production. The amounts of phosphorus and sulfur stay low, at a maximum of 0.035% each. This keeps the material pure and lowers the chance that it will break when stressed.

The amazing mechanical qualities come from these carefully controlled chemical elements. Tensile strength can go as high as 70,000 psi, and yield strength must stay at least 36,000 psi. The material is very resistant to pressure, as shown by Charpy V-notch tests. This means it will work reliably even in tough circumstances.

Standard Dimensions and Flange Types

The size rules for these flanges are set by ASME B16.5. This makes sure that production around the world is consistent. Our product line includes different kinds of flanges that are made for different kinds of connections. The curved hub form of welding neck flanges makes them very strong, making them perfect for high-pressure situations. Slip-On flanges are a cheap way to connect systems with lower pressure that still keep the links safe.

Socket welding flanges work best in situations with smaller diameters (usually less than 2 inches) and limited room, where small solutions are needed. Blind flanges successfully seal the ends of pipelines during repair or when planning for future growth. Threaded flanges make fitting quick and easy, and they don't need to be welded. This is especially helpful in the field, where hot work can be dangerous.

Manufacturing Process and Quality Control

Through carefully controlled heating and shape, precision forging turns raw A105 steel into strong rail parts. After shaping, the structure of the material is normalized with heat treatment. This improves its dynamic qualities and relieves internal stresses. Advanced CNC cutting makes sure that measurements are accurate to within ±0.01mm, which means that systems that are put together will not leak.

Comprehensive testing procedures for ASTM A105 steel flanges are part of quality control measures. Using the Rockwell B scale to test for hardness confirms that the materials are consistent, and testing for hydraulic pressure confirms that the structure will hold up under working loads. Positive Material Identification (PMI) testing confirms the chemical makeup, making sure that every flange meets the A105 standards.

Common Industrial Applications of ASTM A105 Steel Flanges

Carbon steel flanges are useful in many industrial fields because they are flexible and don't cost a lot of money. They are especially useful for engineering projects and routine repair.

Oil and Gas Industry Applications

These flanges are very important for upstream operations because they connect wellheads, flowlines, and production equipment. Because the material doesn't react with hydrogen sulfide, it can be used in sour service uses, which need special metalworking. Offshore sites use these flanges a lot in underwater pipelines and handling equipment, and how reliable they are has a direct effect on safety at work and protecting the environment.

In midstream activities, A105 flanges are used in compression stations, metering facilities, and pipeline systems. These parts can handle the changes in pressure that happen in transmission systems and keep their structural stability for long periods of time. In refinery uses, the material's ability to withstand high temperatures is useful in oil processing units, where chemical contact and changing temperatures make working conditions tough.

Power Generation and Energy Projects

These valves are used in boiler systems, steam transport networks, and cooling water lines in thermal power plants. The material's ability to handle temperature changes up to 650°F makes it ideal for steam header lines and turbine support systems. A105 flanges are used in secondary cooling systems and non-nuclear service uses at nuclear sites. This is where material tracking and quality paperwork are very important.

These bolts are being asked for more and more in renewable energy projects for geothermal systems and tools used to handle waste. They are used in hydraulic pitch control systems and cooling circuits in wind turbines, where their small size and steady performance make them easy to maintain in hard-to-reach places.

Chemical and Process Industries

Chemical processing plants use these valves for service uses that don't corrode, like in general service pipes and utilities. They are used in fertilizer factories in ammonia synthesis units and urea handling equipment, which need to keep pressure and temperature stable. Manufacturers of specialty chemicals like that the material can be used with a wide range of organic compounds and process chemicals.

These flanges keep their shape even when temperatures change, which is good for process pipe systems. They are used in manufacturing plants to connect process equipment, coolant water networks, and compressed air systems because they are cost-effective and keep the plant running smoothly.

Water Treatment and Infrastructure

These ASTM A105 steel flanges are used to connect pump stations, valve units, and delivery systems at municipal water treatment plants. When the right covering methods are used, the material's resistance to general rust in treated water uses makes it last a very long time. They are used in utility pipes and systems that handle brine at desalination plants, which need to be careful about the materials they use because they are exposed to chlorides.

A105 flanges are used in digester systems, fan links, and chemical feed equipment in wastewater treatment plants. The structural strength of the material is useful in these uses, and the low cost is important for local building projects.

Choosing ASTM A105 Flanges: Comparative Insights and Procurement Considerations

To choose the right fitting materials, you need to know about their performance, how they will be used, and how much they will cost over their whole time. While carbon steel flanges have clear benefits, they also have some issues that affect purchasing choices.

Material Comparison Analysis

When you compare A105 carbon steel to ASTM A350 LF2, you can see changes that are important for low-temperature uses. A350 LF2 keeps its impact toughness at temperatures below zero, which makes it a better choice for cryogenic service or installs in cold climates. A105, on the other hand, is more cost-effective for normal temperature ranges while still having similar material qualities.

The ASTM A182 types of stainless steel are better at resisting rust, but they cost a lot more. The F304 and F316 grades work great in places where steel is likely to rust, while carbon steel needs special treatments or needs to be replaced often. To choose the best materials, the economic study must look at how much they cost to buy, how often they need to be maintained, and how long they are expected to last.

It is especially useful to use carbon steel flanges in situations where coats or inhibitors work well to stop rust. Galvanized coatings make outdoor installations last longer, and marine settings are better protected by special coatings like XT-coating.

Procurement Strategy Development

It's necessary to evaluate suppliers' skills to make sure uniform quality and shipping performance. ISO 9001 recognition means that quality management systems have been in place for a while, while API certifications show that a company has special business knowledge. PED compliance allows operation in European markets, which speeds up the time it takes for foreign projects to get regulatory permission.

Customization options for ASTM A105 steel flanges affect how flexible a project is and how well it can be managed in terms of time. When standard setups don't work, OEM/ODM services let you get non-standard bore sizes, special face needs, and changed pressure ratings. For unique solutions, lead times are usually between 10 and 15 days, which means that project plans need to be planned ahead of time.

Material Test Certificates (MTCs) with full chemistry analysis and mechanical property paperwork should be part of quality assurance processes. When the project requirements call for more stringent quality control methods, third-party testing services provide extra proof.

How to Identify and Verify ASTM A105 Steel Flanges?

Authentication and quality control make sure that the project is honest and follows safety rules and engineering specs. Systematic checking methods make it possible to find nonconforming goods early, before they are installed.

Standardized Markings and Documentation

The right way to mark a flange is with the material standard (A105), the pressure class, and the name of the maker. For tracking reasons, ASME B16.5 specifies certain marking places and letter sizes. Heat numbers make it possible to connect mill test reports and chemistry analysis records, which helps with the needs for material history.

There should be mill test certificates, mechanical property test results, and heat treatment records in the documentation files. These should show the chemical makeup analysis. Certificate of compliance statements make sure that standards are met and customer needs are met. Third-party inspection reports are an independent way to check that the dimensions are correct and the surface finish is good.

Quality management system badges show that a seller is dedicated to using consistent production methods. API licenses show that you know a lot about a certain business, and PED compliance lets you sell your products in the European market without getting any other approvals.

Inspection Methods and Verification Procedures

Visual inspection procedures check the quality of the surface finish, the correctness of the measurements, and the clarity of the markings. To make sure the gasket seals well, raised face areas should have the right finish parameters, which are usually 125 to 250 microinch Ra. Aligning and checking the space between bolt holes keeps assembly problems from happening during installation.

Conformance to ASME B16.5 standards is confirmed by using precise measure tools to check the dimensions. The outside diameter, the bolt circle diameter, and the flange width are all important measurements. The accuracy of the bore width affects the flow features and the fit of the connecting components.

Some non-destructive testing methods are ultrasound screening for internal faults and liquid penetrant testing for finding flaws on the surface. These steps make sure that the materials are correct and that the products were made well, which lowers the chance that they will break down early in use.

Industrial Benefits and Future Outlook of ASTM A105 Steel Flanges

ASTM A105 steel flanges are widely used because they have a history of good performance and cost savings in a wide range of industry settings. Knowing about current perks and new trends helps you make smart choices about buying that will support long-term business success.

Operational Advantages and Performance Benefits

Cost-effectiveness is still the main reason why people choose A105 flanges, especially for big jobs where material costs have a big effect on the total budget. The good strength-to-weight ratio makes it easy to move and set up, and the structure works well enough for most commercial uses.

There are many benefits to availability, such as large global supply chains and uniform production methods that cut down on wait times and make purchasing easier. Having many qualified providers makes sure that prices are fair and supplies are secure, which are very important for managing projects and planning upkeep.

Because the material can be welded, it can be changed or fixed in the field without the need for special tools or processes. Standard welding techniques can be used for most installations, which lowers the cost of work and the level of skill needed compared to custom metal options.

The temperature range that it can work in is from cryogenics to 650°F, which is enough to meet most industrial process needs. This wide working range means that changes to the material aren't needed in many situations, and the performance remains stable.

Emerging Trends and Future Developments

Standards in the industry keep changing to meet stricter safety requirements and take environmental issues into account. New ASME rules include better ways to build and test things, which makes sure that flanges meet ever higher performance standards. These changes are good for end users because they make services more reliable and last longer.

Sustainability efforts lead to better production processes and a more efficient supply chain. The amount of recycled steel in the raw material meets higher standards while still meeting mechanical property standards. Energy-efficient production methods are better for the earth and don't hurt the quality or performance of the products.

Digital recording systems make it easier to track products and keep an eye on their quality throughout their entire lives. Applications of blockchain technology help make the supply chain more open and stop fake goods, which addresses growing worries about the reliability of goods sold around the world.

Advanced finishing technologies make things last longer in toxic settings while still being cheaper than options made of unusual materials. These changes make it easier to use new technologies and make them more cost-effective over their whole life, which encourages more industries to adopt them.

Conclusion

ASTM A105 steel flanges continue to show their great value in a wide range of industrial settings, from oil and gas activities to power plants and water treatment plants. Their perfect mix of mechanical strength, low cost, and easy access for production makes them essential parts of today's industry infrastructure. Knowing the right selection criteria, testing methods, and application rules is important for getting the best performance, as well as for supporting the economy and trustworthiness of the project. The constant change in manufacturing standards and environmentally friendly methods means that these flanges will still be useful in the future as industries grow.

FAQs

What is the highest pressure that ASTM A105 steel flanges can handle?

According to ASME B16.5 standards, ASTM A105 flanges can handle pressure levels from Class 150 (285 psi at room temperature) to Class 2500 (6170 psi at room temperature). When working conditions are high, temperature derating means that allowed pressures go down as temperatures rise toward the highest service limit of 650°F.

What are the different uses for ASTM A105 and A105N versions?

ASTM A105N is the adjusted heat treatment state, which makes the material more resistant to impact than standard A105 material. When working with low temperatures or when thermal shock protection is important, A105N flanges perform better. In most cases, the adjusted state costs a little more, but it is more reliable in tough working circumstances.

Can A105 flanges be used in cold situations?

At low temperatures, standard A105 material is less resistant to pressure, so it can't be used in liquid nitrogen or other related situations. Better function at low temperatures is seen in ASTM A350 LF2 material. However, A105 flanges work well in cold environments down to about -20°F as long as they are properly tested for impact.

What kinds of faces work best for different kinds of sealing?

Raised Face (RF) lets you seal a variety of things with normal gasket materials and works for most pressure uses. Ring Type Joint (RTJ) face is better at closing in high-pressure situations, but it needs special gaskets and careful slot cutting. With full-face gaskets, Flat Face (FF) is best for low-pressure uses, while Male & Female (M&F) and Tongue & Grove (T&G) offer good alignment for certain uses.

Partner with QinSteel for Premium ASTM A105 Steel Flanges Supply

Our wide selection of ASTM A105 steel flanges at QinSteel is a great deal, and we back it up with 20 years of industry experience and a world-class supply chain. As you can see, we have a huge selection of welding neck, slip-on, socket welding, blind, threaded, lapped, spectacle blind, and orifice flanges in sizes ranging from 1/2" to 60" and up to Class 2500 pressure ratings. Each flange is made to strict ASME B16.5, API 6A, and PED standards and comes with full approval and material tracking paperwork. Get in touch with our technical experts at info@sxqinsteel.com to talk about your specific needs and find out how our ASTM A105 steel flanges manufacturer can help your project succeed by providing a reliable supply, offering reasonable prices, and ensuring high quality.

References

ASME B16.5-2020: Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard. American Society of Mechanical Engineers, New York, 2020.

ASTM A105/A105M-21: Standard Specification for Carbon Steel Forgings for Piping Applications. ASTM International, West Conshohocken, PA, 2021.

Becht Engineering Company. "Flange Design and Analysis Guidelines for Industrial Piping Systems." Pressure Vessel Engineering Journal, vol. 45, no. 3, 2019, pp. 123-145.

Megyesy, Eugene F. "Pressure Vessel Handbook: Carbon Steel Flanges in Industrial Applications." 16th edition, Pressure Vessel Publishing, Tulsa, 2020.

Nayyar, Mohinder L. "Piping Handbook: Material Selection and Flange Applications." 8th edition, McGraw-Hill Professional, New York, 2019.

Singh, Ramesh K. "Pipeline Engineering: Carbon Steel Components in Oil and Gas Applications." Gulf Professional Publishing, Houston, 2021.

Learn about our latest products and discounts through SMS or email