- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

DIN EN 1092-1 Flange

DIN EN 1092-1 Flange: Precision Engineered for Global Industrial Excellence

Xi’an QinSteel Trading Co., Ltd – Your trusted partner for DIN EN 1092-1 Flanges that meet the highest European and international standards. With GMP-certified production facilities and over 15 years of expertise, we deliver EN 1092-1 compliant flanges with unmatched precision, speed, and reliability. Whether you need standard configurations or custom solutions, our advanced engineering team ensures your piping systems perform flawlessly under extreme pressures and temperatures.

Why Choose DIN EN 1092-1 Flanges?

The products are the backbone of industrial piping systems requiring strict adherence to pressure, material, and dimensional standards. Here’s what makes our flanges stand out:

- Full Compliance: Manufactured to DIN EN 1092-1 specifications, ensuring seamless integration with European and global pipeline networks.

- Unmatched Versatility: Available in sizes from DN 10 to DN 3600 and pressure ratings from PN 6 to PN 400.

- Material Diversity: Carbon steel, stainless steel (304/316L), and duplex alloys for corrosion resistance and durability.

- Custom Solutions: Tailored dimensions, bolt patterns, and facings (RF, RTJ, Spigot) to meet unique project needs.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN 15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Key Advantages for Your Projects

1. Zero-Risk Compliance

Every DIN EN 1092-1 Flange undergoes rigorous testing (dimensional checks, NDT, pressure tests) to guarantee PED 2014/68/EU and ISO 9001 compliance.

2. Rapid Order Fulfillment

With 5,000+ tons of raw material in stock, we cut lead times by 30%—delivering bulk orders in as few as 15 days.

3. Damage-Proof Logistics

Triple-layer packaging (anti-rust coating, vacuum sealing, reinforced crates) ensures flawless delivery, even to remote offshore sites.

4. Global Certification Ready

Traceable EN 10204 3.1/3.2 material certificates, NACE MR0175, and ATEX compliance for explosive environments.

Applications Built to Last

Our EN 1092-1 compliant flanges are trusted in:

- Oil & Gas: High-pressure pipelines, refinery systems.

- Chemical Processing: Corrosion-resistant alloy flanges for acidic environments.

- Power Generation: Steam lines and turbine connections.

- Water Treatment: Large-diameter flanges (up to DN 3600) for municipal projects.

Why Partner With Us?

- 15+ Years of Expertise: 200+ global projects completed annually.

- End-to-End Support: Dedicated project managers from RFQ to delivery.

- OEM/ODM Flexibility: Modify bore sizes, facings, or materials—no MOQ for custom designs.

Quality Control

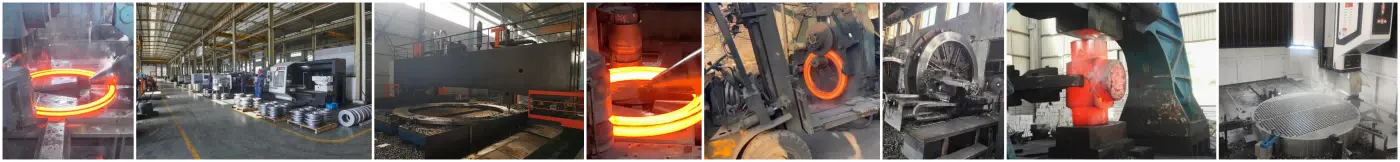

Factory Equipment

Shipping Packaging

FAQs: Your Questions, Answered

Q: Can you provide the products for sour service (H2S environments)?

A: Yes! Specify NACE MR0175 compliance in your inquiry for H2S-resistant materials like A182 F55.

Q: How do you ensure flange quality during mass production?

A: Automated CNC machining (±0.1mm accuracy) paired with 100% pressure testing and surface inspections.

Q: What's the lead time for 1,000 units of PN40 weld neck flanges?

A: 18–22 days for in-stock materials. Contact us for expedited options.

Q: Do you offer samples for quality verification?

A: Yes—request samples via info@sxqinsteel.com to evaluate fit, finish, and performance.

Contact Us

Xi'an QinSteel Trading Co., Ltd simplifies procurement for oil & gas, energy, and infrastructure sectors.

📧 Email: info@sxqinsteel.com

Your Trusted DIN EN 1092-1 Flange Supplier—Where Precision Meets Reliability.

Learn about our latest products and discounts through SMS or email