- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

A335 P22 Pipe

Xi 'An QinSteel Trading Co., Ltd | Global Manufacturer & Supplier of A335 P22 Pipes for High-Temperature Applications

When you need A335 P22 Pipe solutions that withstand extreme heat and pressure, our seamless chrome-moly alloy pipes deliver unmatched reliability. Designed for refinery systems, power plants, and petrochemical applications, these pipes combine superior creep resistance (up to 580°C/1076°F) with ASME-certified manufacturing. With 30% pre-stocked inventory and global certifications, we ensure your high-temperature projects stay on schedule.

Product Overview

The product is a chromium-molybdenum alloy steel seamless pipe engineered for high-pressure steam, hydrocarbons, and corrosive fluids. Manufactured under strict GMP guidelines, our pipes meet ASTM/ASME standards for chemical composition, tensile strength (≥415 MPa), and dimensional precision. Available in diameters from 1/4" to 24", they’re ideal for boilers, heat exchangers, and process piping requiring long-term thermal stability.

Key Specifications

| Parameter | Details |

|---|---|

| Outer Diameter | 0.5" to 24" (Customizable) |

| Wall Thickness | SCH 10 to SCH 160 |

| Length | 6m to 12m (Cut-to-Size Available) |

| Standards | ASTM A335, ASME SA335 |

| Pressure Rating | Up to 3000 PSI |

Why Our A335 P22 Pipes Stand Out?

✅ High-Temperature Durability

Chromium (2.0-2.5%) and molybdenum (0.9-1.1%) enhance oxidation resistance, making these pipes ideal for sustained 580°C environments.

✅ Seamless Construction

Advanced extrusion technology eliminates weld seams, ensuring uniform strength and leak-proof performance under high pressure.

✅ Global Compliance

Certified to ASME B36.10, EN 10216-1, and ISO 9001, with optional NACE MR0175 compliance for sour gas service.

✅ Urgent-Order Ready

15,000-metric-ton stock supports 7-day delivery to Europe, Asia, and the Americas.

✅ Customization

Tailor wall thickness, length, or end preparations (bevelled/threaded) within 15 days.

Applications

- Refineries: High-pressure steam lines and hydrocarbon transfer.

- Power Plants: Boiler tubes and superheater coils.

- Petrochemical: Corrosive fluid handling in ethylene crackers.

- Shipbuilding: High-integrity piping for LNG carriers.

Built for Your Peace of Mind

Rigorous Quality Control

Every A335 P22 Pipe undergoes ultrasonic testing (UT), hydrostatic pressure checks, and hardness validation. Mill Test Certificates (EN 10204 3.1) are provided with every shipment.

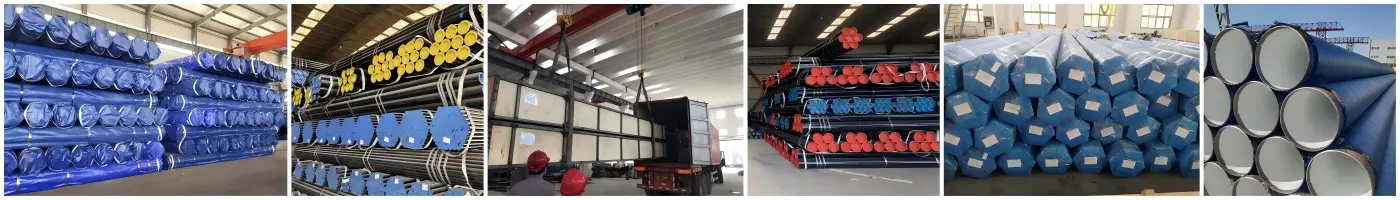

Climate-Smart Packaging

Pipes are wrapped in anti-corrosion VCI film and secured in wooden crates to prevent transit damage—even in humid or saline environments.

15+ Years of Expertise

Our GMP-certified facility combines advanced metallurgy knowledge with responsive 24/7 technical support for material selection and installation guidance.

Quality Control

Factory Equipment

Shipping Packaging

FAQs

Q: What’s the lead time for non-standard sizes?

A: Custom orders ship in 15-25 days, depending on complexity.

Q: Are your pipes suitable for H2S environments?

A: Yes! We offer NACE MR0175-compliant options for sour service.

Q: Do you provide samples?

A: Sample pipes (1-2 meters) are available for testing.

Q: How do you ensure on-time delivery?

A: 30% of our inventory is reserved for urgent orders, with real-time logistics tracking.

Contact Us

Email info@sxqinsteel.com for a A335 P22 Pipe quote or technical datasheet. Our team responds within 4 hours!

Learn about our latest products and discounts through SMS or email