- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

SW Socket Weld Flanges

Xi 'An QinSteel Trading Co., Ltd | High-Performance SW Socket Weld Flanges Manufacturer & Global Supplier

When you need reliable connections for high-pressure piping systems, SW Socket Weld Flanges offer unmatched durability and precision. Designed to meet ASME B16.5, API 6A, and EN 1092-1 standards, our flanges ensure leak-proof performance in critical oil, gas, and industrial applications. With sizes ranging from ½" to 60" and pressure ratings up to CLASS 2500, they’re engineered to handle extreme conditions while maintaining structural integrity.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN 15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Material Excellence

Our SW Socket Weld Flanges are crafted from ASTM A105 carbon steel, A350 LF2 for low-temperature environments, and corrosion-resistant alloys like A182 F304/F316. Whether your project requires standard or exotic materials (e.g., Duplex, Inconel), we ensure compliance with global standards like BS 4504 and JIS B2220.

Why Our SW Socket Weld Flanges Stand Out?

1. Precision Engineering: Machined to ±0.1mm tolerances for perfect alignment and reduced turbulence.

2. High-Pressure Resilience: Tested up to 1.5x rated pressure to guarantee leak-free operation.

3. Custom Solutions: Modify dimensions, coatings, or materials to fit unique project needs.

Trusted Applications

- Oil and gas pipelines

- Petrochemical refineries

- Power generation plants

- Hydraulic systems requiring CLASS 900+ ratings

Why Choose QinSteel?

✅ GMP-Certified Production: Every flange undergoes 100% dimensional checks and NDT testing.

✅ Global Compliance: API 6A, PED, and ADNOC certifications included.

✅ Rapid Delivery: 70% of orders ship within 48 hours, even for bulk requests.

Quality Assurance

We perform:

- Material traceability via mill test reports

- Ultrasonic testing (UT) for weld integrity

- PMI verification to confirm alloy composition

Secure Global Shipping

Flanges are coated with anti-corrosion solutions and packed in steel-reinforced crates. We offer EXW, FOB, or DDP terms to simplify logistics.

Quality Control

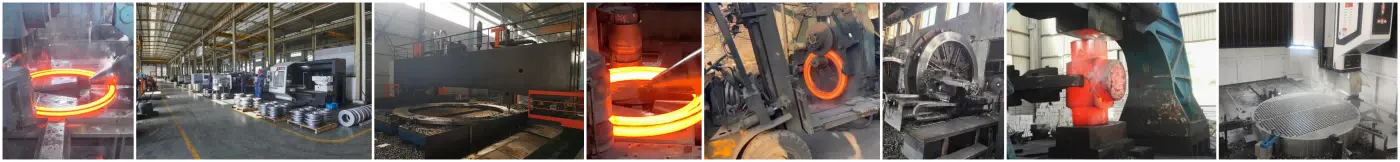

Factory Equipment

Shipping Packaging

FAQs

Q: Do your products meet API 6A for sour service?

A: Absolutely. We provide NACE MR0175-compliant options for harsh environments.

Q: Can you customize flanges for non-standard sizes?

A: Yes! Our R&D team delivers OEM solutions in 3–5 weeks.

Q: How do you ensure defect-free products?

A: Every batch undergoes UT, RT, and hydrostatic testing before shipment.

Contact Us

Need a quote or technical support for SW Socket Weld Flanges? Contact us at info@sxqinsteel.com for fast, personalized service.

Learn about our latest products and discounts through SMS or email