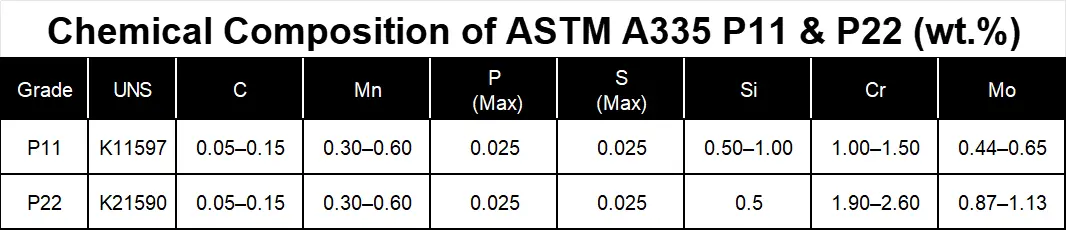

For high-temperature uses, ASTM A335 P11 and P22 pipes' chemical makeup is very important in figuring out how they will work. The A335 P11 pipe is made of different metals that make up about 1.00-1.50% chromium and 0.44-0.65% molybdenum. These allow the pipe to better fight rust and creep when compared to pipes made of carbon steel. When choosing materials for power generation, petroleum processing, and oil refining where high temperatures and pressures make things hard on normal pipe systems, it is important to know how these materials are different from each other.

Understanding the Chemical Composition of A335 P11 and P22 Pipes

ASTM A335 is about seamless ferritic alloy-steel pipes that are used a lot in high-temperature settings. The standard lists certain chemistry needs that make the P11 and P22 types different from regular carbon steel pipes. The pipes' ability to handle temperature stress, fight rust, and stay strong under difficult working conditions is directly affected by these elements.

Chemical Elements in P11 Grade Steel

The A335 P11 pipe has been designed with just the right amounts of different metals to make it work better at high temperatures. With 0.05% to 0.15% of carbon, it has enough strength while still being able to be welded. A chromium level of 1.00-1.50% forms oxide layers that protect the metal and keep it from oxidizing even when the temperature is high. Molybdenum makes the material stronger at high temperatures and more resistant to creep. In this case, it makes up 0.44-0.65% of the total. Silicon between 0.50% and 1.00% removes oxygen and makes the steel stronger, and manganese between 0.30% and 0.60% makes the steel easier to form and work with when hot.

P22 Grade Chemical Composition

P22 steel has a higher metal value than P11, which makes it better for more difficult uses. When the chromium level rises to between 1.90% and 2.60%, it gains better resistance to both oxidation and scaling at temperatures over 550°C. When the molybdenum content is raised to between 0.87% and 1.13%, the material's resistance to deformation over time and its long-term stability are greatly improved. To keep the weldability of P22 uses while also meeting their higher strength needs, the carbon level is kept between 0.05% and 0.15%.

Comparative Analysis of P11 and P22 Compositions

The different compositions of the P11 and P22 grades lead to different achievement traits. P22 can work at temperatures as high as 650°C because it has more chromium and molybdenum than P11, which usually works at temperatures up to 600°C. P22 has more metal than before, which makes it better at resisting rust in places that have sulfur in them. This makes it the best choice for processing heavy oil and for use in power plants that burn coal. P11, on the other hand, is a better choice for uses at reasonable temperatures where the better qualities of P22 aren't needed.

Mechanical Properties and Performance Correlation with Chemical Composition

The way A335 P11 seamless pipe and A335 P22 pipes behave mechanically is directly related to how they are made chemically. Procurement workers need to know about these links so they can choose the right materials for different working situations. This also helps them find the best mix between cost and performance.

Strength Characteristics and Temperature Resistance

The chemical makeup of these alloy steel pipes directly affects their bending strength and tensile strength. The A335 P11 pipe has a minimum tensile strength of 415 MPa and a yield strength greater than 205 MPa at room temperature. The chromium-molybdenum material has great creep resistance, which makes it possible for the system to keep working under a lot of stress at high temperatures. P22 has higher strength because it has more metal in it. Its tensile strength is 485 MPa, and it has better resistance to creep breakage, which makes it useful for long-term service in difficult situations.

The way that each grade is made up chemically affects how well it can survive high and low temperatures. P11 keeps its strength up to 600°C and also has enough flexibility to be used in thermal cycle applications. The molybdenum percentage is important for stability at high temperatures because it stops carbide precipitation, which could make the grain boundaries weaker. The better makeup of P22 lets it work at temperatures up to 650°C, and it resists scaling better in environments where rusting occurs.

Corrosion Resistance and Environmental Performance

How well these alloy steels prevent rust depends a lot on how much chromium is in them and how stable their microstructure is. P11 has enough resistance to general rust in neutral settings. On the other hand, P22 has a higher chromium content, which gives it better protection against acidic acids and sulfur compounds. Both grades need to be heated correctly so that they can fight rust as much as possible by making sure that the carbides are evenly spread and leftover stresses that could speed up targeted attack are lowered.

Impact Properties and Low-Temperature Service

The way a material is made chemically affects its impact toughness and how well it works at low temperatures. The carbon that is managed in both grades keeps enough notch toughness for uses that involve thermal shock. At room temperature, P11 grade usually has impact values over 27 Joules. P22 keeps about the same amount of toughness even though it is stronger. Proper normalization heat treatment makes the microstructure perfect for pressure tank uses where strength and hardness need to be matched.

Practical Implications for Procurement and Application

When buying A335 P11 pipe and P22 pipes, you need to think about the chemicals in them, as well as how they will be used and how much they will cost. The selection method finds the best grade for certain uses by checking temperature ranges, pressure conditions, toxic surroundings, and standards for long-term reliability.

Application-Specific Selection Criteria

When steam pipe and superheater tubes work at temperatures under 580°C, power plants usually use P11 grade because it has balanced qualities that make it stable and cheap. When better resistance to rust makes it worth the extra cost, P22 is often used in hydrogen service uses and heavy oil handling units. Chemical companies may pick a grade based on how hot the processes are and whether or not there are toxic chemicals that could break down the material faster.

The seamless manufacturing process makes sure that the whole thickness of the pipe wall has the same chemical makeup. This gets rid of any possible weak spots that could happen with soldered construction. In uses with a lot of pressure, this regularity is especially important because any changes in the makeup could cause stress to build up and fail too soon.

Quality Assurance and Manufacturing Considerations

The way A335 pipes are made affects their chemical makeup and how well they work a lot. Rotary cutting keeps the makeup of the material intact and avoids the separation effects that are common in welding methods. Heat treatments, like leveling at 900-950°C, make the microstructure better for the situations in which the material will be used and make sure that the whole cross-section of the material is chemically uniform.

Material approval usually means confirming chemical makeup with spectrometric testing, checking mechanical properties, and doing an inspection that doesn't damage the part to make sure it was made correctly. These certificates give buying teams proof of chemical compliance and performance skills that are needed for important building projects.

Comparative Insights: A335 P11 vs Other Pipe Grades and Materials

Procurement pros make good choices based on performance needs, material supply, and cost when they know how A335 P11 and P22 stack up against other materials. It is clear from these examples that chromium-molybdenum alloy steels are the best choice for uses that need to work at very high temperatures.

P11 versus P22 Performance Analysis

A performance comparison between the P11 and P22 grades shows that each has its own benefits depending on the situations in which it is used. P11 is a great deal for the price in situations with mild temperatures where the 600°C service limit meets the needs of the operation. The smaller metal percentage lowers the cost of the material and provides enough rust protection for most commercial settings. P22 explains its high price by saying that it has better strength at high temperatures, better resistance to rust, and a longer service life in tough situations where the temperature is close to 650°C.

P22 usually costs 15% to 25% more than P11 because it has more metal and needs special handling. Cost analysis usually shows this. But in important situations where the cost of being offline for a period of time is much higher than the saves from not using any material, the longer service life and lower need for upkeep usually make up for the higher original cost.

Comparison with Carbon Steel Alternatives

A106 Grade B and other standard carbon steel pipes don't work as well at high temperatures as chromium-molybdenum metals do, so they can only be used in services below 450 °C. The A335 P11 pipe resists creep and rust better than others, so it lasts much longer in high-temperature settings. Even though carbon steel is cheaper at first, for systems that run at high temperatures, alloy steel pipes have a longer lifespan and are more reliable, so they usually have lower lifecycle costs.

Seamless versus Welded Manufacturing Impact

Seamless manufacturing gives you better chemical consistency than welding methods. This is especially important for metal steels because changes in the makeup can change how the material performs. The lack of weld gaps makes sure that there are no weak spots and that the pipe's mechanical features are the same all the way around. This benefit of making comes in handy when reliable performance is needed beyond what welding building can offer. This is especially true in high-pressure situations.

QinSteel: Your Trusted Partner for Premium A335 P11 Pipe Solutions

For the last twenty years, Xi'an QinSteel Trading Co., Ltd. has been making and delivering high-quality A335 P11 and P22 pipes for difficult industrial uses. Our wide range of products includes seamless alloy steel pipes in sizes from 1/4" to 24" (13.7 mm to 610 mm) with wall thicknesses from Schedule 5s to XXS. This helps meet the needs of different projects in a variety of industries.

Using modern rotary cutting technology to make our A335 P11 pipes guarantees that each one has the same chemical makeup and mechanical qualities all the way through. The smooth design gets rid of weak parts and makes the service much more reliable, even under high-pressure circumstances. Our seven-step proof process, which includes spectrometry analysis of raw materials, exact heat treatment at 900-950°C, and thorough non-invasive testing to make sure the performance standards are met, helps us keep strict quality control.

Quality verification is still the most important part of how we make things. Every batch has to pass a lot of tests, such as hydraulic testing at 1.5 times the design pressure, checking wall thickness with ultrasound, and finding surface flaws with eddy currents. Our goods meet global standards such as ASTM A335, ASME SA335, EN 10216-1, and EN 10216-2. EN 10204 3.1/3.2 mill test certificates give full material tracking paperwork.

Our global transportation network makes sure that deliveries are always on time with stores in the UAE, the US, and Singapore that are placed there for a reason. Our supply chain management keeps prices low and wait times short at 10-15 days for pressing orders because we have more than 15,000 tons of product ready to ship. Custom engineering services meet the unique needs of the power generation and petroleum businesses with custom sizes, protected coats, and more thorough testing methods.

Conclusion

Knowing the chemicals that make up A335 P11 and P22 pipes helps people choose the right materials for commercial uses at high temperatures. The P11 grade has a carefully measured metal content that makes it work very well at a low cost. The P22 grade has even better performance for tougher service conditions. A good look at both the chemical makeup of the material and the needs of the business makes sure that the best material is chosen to match performance, dependability, and cost. With new technologies and quality assurance methods in production, these chromium-molybdenum alloy steels keep on serving important building uses where normal materials can't meet the needs of performance.

FAQs

A335 P11 and P22 pipes: what are the main chemistry changes between them?

P11 has 0.44-0.65% molybdenum and 1.00-1.50% chromium, but P22 has higher amounts of both chromium and molybdenum, with 1.90-2.60% chromium and 0.87-1.13% molybdenum. Because of these changes, P22 has better high-temperature strength and rust protection, so it can work at temperatures up to 650°C, while P11 can only work up to 600°C.

How does chemical composition influence the heat resistance of these pipes?

When there is more chromium, it makes safe oxide layers that don't scale or oxidize at high temperatures. By stopping carbide formation and fixing the microstructure, molybdenum improves resistance to creep. The equal makeup in both grades keeps the structure intact during heat cycles, which is common in power plants and refineries.

Can I use A335 P11 pipes as a cost-effective alternative to P22 for my high-temperature application?

This relies on the way you are currently working. P11 works really well at temperatures up to 600°C and is 15-25% cheaper than P22. But if your application has temperatures over 580°C, harshly acidic settings, or needs to last a long time, the better makeup of P22 may make it worth the extra cost because it is more reliable and cheaper to maintain.

Partner with QinSteel for Superior A335 P11 Pipe Solutions

Are you ready to make your high-temperature piping systems work better with top-of-the-line A335 P11 pipe options? QinSteel's large stock and technical knowledge make sure you get the right materials for your important projects. We make our seamless alloy steel pipes to both ASTM and ASME standards. They are the most reliable choice for power generation, petroleum, and industrial processing systems. Talk to our technology experts about your project needs and get fair, custom quotes. To learn more about our full range of A335 P11 pipe manufacturing skills and find out how our focus on quality can help your project succeed, email us at info@sxqinsteel.com.

References

American Society for Testing and Materials. "Standard Specification for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service." ASTM A335/A335M-19.

Harvey, John F. "Theory and Design of Pressure Vessels." 2nd Edition. Van Nostrand Reinhold Company, 1985.

Bhadeshia, H.K.D.H. and Honeycombe, Robert. "Steels: Microstructure and Properties." 3rd Edition. Butterworth-Heinemann, 2006.

Metals Handbook Committee. "Properties and Selection: Irons, Steels, and High-Performance Alloys." ASM International Handbook Volume 1, 10th Edition, 1990.

Viswanathan, R. "Damage Mechanisms and Life Assessment of High-Temperature Components." ASM International, 1989.

Smith, William F. and Hashemi, Javad. "Foundations of Materials Science and Engineering." 4th Edition. McGraw-Hill Education, 2006.