- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

A335 P11 Pipe

Xi 'An QinSteel Trading Co., Ltd – Your Trusted Partner for Premium A335 P11 Pipes

When your project demands A335 P11 Pipe solutions that withstand extreme heat and pressure, you need a partner who combines material science expertise with precision manufacturing. Our chromium-molybdenum alloy steel pipes are engineered for critical applications in power generation, refineries, and petrochemical systems, delivering unmatched performance under temperatures up to 600°C (1112°F).

Why A335 P11 Pipes?

The product is a seamless, high-temperature alloy steel pipe designed for environments where standard carbon steels fail. With a chromium content of 1.00-1.50% and molybdenum (0.44-0.65%), it offers superior oxidation resistance and creep strength, making it ideal for:

- Power plant steam lines

- Oil and gas refinery piping

- High-pressure boiler systems

- Petrochemical processing units

Technical Specifications

| Parameter | Specification |

|---|---|

| Outer Diameter | 1/4" – 24" (13.7–610mm) |

| Wall Thickness | Sch5s to XXS (3–50mm) |

| Length | 1m – 12m (customizable) |

| Standards | ASTM A335, ASME SA335 |

| Temperature Range | -29°C to 600°C |

| Pressure Rating | Customizable per project needs |

Key Advantages of Our A335 P11 Pipes

✅ Seamless Reliability

Eliminate weak joints with pipes manufactured using advanced rotary piercing technology, ensuring uniform strength for high-pressure service.

✅ Global Compliance

Pre-certified to ASTM, ASME, ISO, and EU PED standards, with full traceability via mill test reports (EN 10204 3.1/3.2).

✅ Optimized Inventory

15,000+ tons of ready-to-ship stock across our UAE, USA, and Singapore hubs, reducing lead times to 10-15 days for urgent orders.

✅ Custom Engineering

Tailor dimensions, coatings (FBE, 3LPE), or testing protocols (hydrostatic, ultrasonic) for specialized refinery or power plant needs.

Built for Extreme Conditions

Our A335 P11 Pipe chromium-molybdenum alloy steel pipes undergo proprietary heat treatment to enhance microstructural stability, ensuring:

- Tensile strength ≥ 415 MPa

- Yield strength ≥ 205 MPa

- Hardness ≤ 197 HB

- Impact-tested for -29°C low-temperature environments

Why Choose Xi 'An QinSteel?

1. End-to-End Certification

Every batch includes ISO 9001, API 5L, and NACE MR0175 certifications, pre-validated for Middle Eastern, European, and North American projects.

2. Rapid Response Logistics

Strategic regional warehouses and JIT programs guarantee on-time delivery, even for last-minute MRO purchases.

3. 24/7 Technical Support

Our metallurgy experts provide weld procedure specifications (WPS) and failure analysis to keep your operations running smoothly.

Quality Assurance

We enforce a 7-step quality protocol:

1. Raw material spectrometry analysis

2. Seamless pipe forming via rotary piercing

3. Normalizing heat treatment (900-950°C)

4. Eddy current testing (ECT) for surface flaws

5. Hydrostatic testing at 1.5x design pressure

6. Ultrasonic testing (UT) for wall thickness uniformity

7. Final dimensional inspection

Quality Control

Factory Equipment

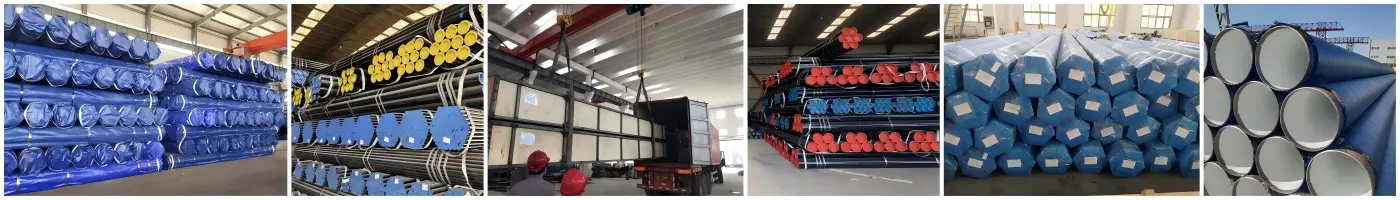

Shipping Packaging

FAQs

Q: Can you provide the products for sour service environments?

A: Yes! We offer NACE MR0175-compliant pipes with enhanced sulfide stress cracking resistance.

Q: What’s the MOQ for customized lengths?

A: 5 tons (negotiable for repeat clients). Custom lengths up to 18m available.

Q: Do you offer anti-corrosion coatings?

A: Absolutely. Choose from FBE, 3LPE, or galvanized coatings for harsh chemical exposure.

Q: How do you ensure on-time delivery to remote sites?

A: Our partnered logistics network covers air, sea, and land freight with real-time GPS tracking.

Contact Us

Email: info@sxqinsteel.com

Submit your A335 P11 Pipe specifications by 5 PM CST for a same-day quote with certification details and lead times.

Xi 'An QinSteel Trading Co., Ltd – Engineering Excellence in Every Pipe Since 2008.

Learn about our latest products and discounts through SMS or email