- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

ASME B36.10 Pipe

ASME B36.10 Pipe Manufacturer | Global Supplier for High-Volume Procurement

Looking for ASME B36.10 pipes that meet strict industrial standards while offering flexibility for your project needs? At Xi’an QinSteel, we specialize in manufacturing pipes that deliver precision, durability, and compliance. Whether you’re working on high-pressure oil and gas systems, petrochemical plants, or power generation infrastructure, our ASME B36.10-certified pipes are engineered to exceed expectations. With a global inventory and rapid delivery, we ensure your projects stay on track without compromising quality.

Product Description

The products are essential for industrial systems requiring dimensional accuracy and structural reliability. Our pipes are available in seamless or welded constructions, catering to diverse pressure and temperature demands. Designed for applications like oil refineries, LNG terminals, and steam distribution networks, they combine strict adherence to ASME standards with customizable features like threading, bevelled ends, and protective coatings.

Specifications

| Parameter | Details |

|---|---|

| Standards | ASME B36.10/10M, ISO 9001, PED |

| Sizes | 1/8" to 80" (10.3mm – 2032mm) |

| Wall Thickness | Sch5s to XXS |

| Materials | Carbon Steel, Alloy Steel, Stainless |

| Pressure Rating | Up to 5000 PSI (Customizable) |

| Length | 1m – 12m |

Material Specifications

- Carbon Steel: ASTM A106 Gr.B, A53 Gr.B (ideal for high-temperature environments).

- Low-Temperature Steel: ASTM A333 Gr.6/Gr.11 (suited for cryogenic applications).

- Alloy Steel: ASTM A335 P11/P22/P91 (excellent for extreme heat and pressure).

Why Our ASME B36.10 Pipes Stand Out?

✅ Precision Engineering: Every pipe meets ASME B36.10 tolerances for outer diameter, wall thickness, and straightness.

✅ Dual Manufacturing Options: Choose seamless for high-pressure systems or welded for cost-efficient general use.

✅ Global Compliance: Certifications include ISO, PED, and NACE, ensuring suitability for EU, Middle Eastern, and North American projects.

✅ Custom Solutions: OEM/ODM services for non-standard sizes, coatings, or threading.

Applications

- Oil & Gas: Transmission pipelines, refinery process lines.

- Power Generation: High-pressure steam lines, boiler systems.

- Petrochemicals: Corrosive fluid transport, heat exchangers.

Why Choose Xi’an QinSteel?

1. Expert R&D Team: Over a decade of experience optimizing ASME B36.10 pipe designs for harsh environments.

2. Fast Turnaround: Large stock of common sizes; bulk orders ship in 15–30 days.

3. End-to-End Quality Control: From material sourcing to final inspection, we ensure zero defects.

4. Logistics Assurance: Secure packaging and global shipping partnerships.

Quality Assurance

Every batch undergoes rigorous testing, including hydrostatic exams, ultrasonic testing, and chemical analysis. Mill Test Certificates (MTC) and full material traceability are provided.

Quality Control

Factory Equipment

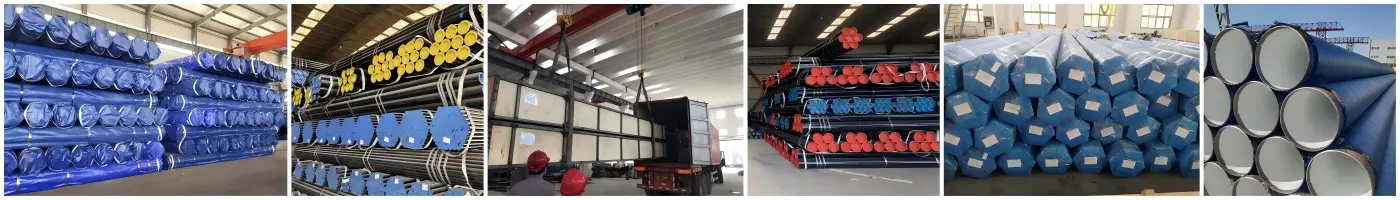

Shipping Packaging

FAQ

Q: Can you supply pipes for sour service (H₂S environments)?

A: Yes! We offer ASTM A333 Gr.6 pipes with NACE MR0175 compliance.

Q: Do you support urgent orders?

A: Stocked items ship in 7 days. Contact us for expedited production.

Q: What packaging do you use?

A: Anti-rust coatings, wooden crates, and waterproof wrapping to prevent transit damage.

Q: Is customization available for pipe ends?

A: Absolutely—we provide bevelled, threaded, or grooved ends per your specs.

Contact Us

Need a reliable partner for ASME B36.10 pipes? Email us at info@sxqinsteel.com for samples, quotes, or technical support. Let’s build your next project together!

Learn about our latest products and discounts through SMS or email