- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

ASME B18.31.1M Bolt

Trusted Manufacturer of ASME B18.31.1M Bolts for Industrial Machinery

Global supplier of precision-engineered ASME B18.31.1M-compliant bolts, backed by GMP-certified production and scalable OEM/ODM solutions.

Precision ASME B18.31.1M Bolts Built for Demanding Industries

When you need bolts that meet rigorous industrial standards, ASME B18.31.1M Bolts deliver unmatched reliability. Designed for heavy machinery, energy infrastructure, and harsh environments, these high-strength fasteners combine strict dimensional accuracy with superior load-bearing capacity. Whether you’re assembling wind turbines or maintaining oil rigs, our bolts ensure long-term performance under extreme stress, vibrations, and corrosion.

Technical Specifications

| Parameter | Specification |

|---|---|

| Standard | ASME B18.31.1M |

| Diameter Range | M6 to M64 |

| Length Range | 20mm to 500mm |

| Thread Type | Metric Coarse/Fine, UNC, UNF |

| Strength Grade | Grade 8.8, 10.9, 12.9 |

| Tolerance | ±0.05mm (precision-machined) |

Material & Customization Options

- Materials: Alloy Steel (SAE 4140/4340), Stainless Steel (AISI 304/316), Carbon Steel (Grade 10.9+).

- Coatings: Zinc Plating, Hot-Dip Galvanizing, Dacromet, or Plain finishes for corrosion resistance.

- Custom Designs: Tailor thread specifications, coatings, and packaging to your project needs.

Why ASME B18.31.1M Bolts Are Essential for Your Projects?

1. Engineered for Extreme Conditions

From offshore platforms to wind farms, ASME B18.31.1M Bolts withstand high torque, temperature fluctuations, and fatigue. Grade 12.9 variants offer exceptional tensile strength for critical connections.

2. Global Compliance Made Simple

Pre-certified to meet ASME, ISO, API, and regional standards (e.g., PED, NACE MR0175), our bolts simplify approvals for international projects.

3. Faster Turnarounds, Lower Costs

With 50,000+ metric tons in stock, we ship standard specs in 7–15 days. Bulk pricing reduces costs without compromising quality.

Applications Across Industries

- Oil & Gas: Corrosion-resistant bolts for H2S environments, compliant with API 20E and NACE standards.

- Wind Energy: High-fatigue bolts tested per EN 14399 for turbine towers and nacelles.

- Mining & Construction: Heavy-duty fasteners for equipment exposed to abrasive conditions.

Why Partner With Us?

✅ GMP-Certified Production: Every batch undergoes 100% dimensional checks and material traceability.

✅ R&D Expertise: Prototype custom designs in 7 days using advanced CNC machining.

✅ Sustainable Practices: Eco-friendly coatings and recyclable packaging align with ESG goals.

✅ Global Logistics: Regional warehouses in the US, EU, and Middle East ensure JIT delivery.

Quality Control

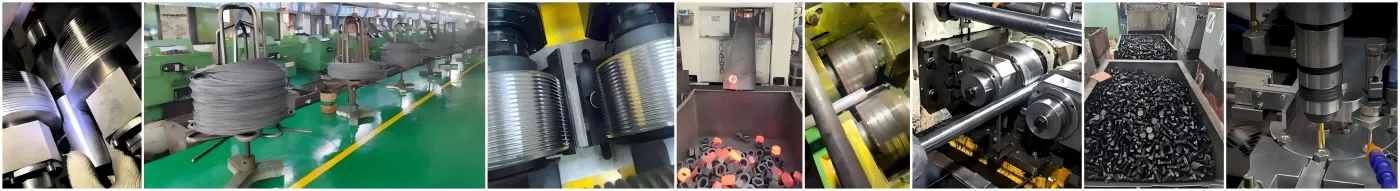

Factory Equipment

Shipping Packaging

FAQ

Q: Can you customize bolts beyond standard ASME B18.31.1M specs?

A: Absolutely! Our team adapts materials, threads, and coatings for unique requirements.

Q: How do you ensure corrosion resistance?

A: Coatings like hot-dip galvanizing are tested per ISO 9227 salt spray standards.

Q: What certifications do you provide?

A: We include material test reports (MTRs) and compliance certificates with every order.

Q: What's the MOQ?

A: 1,000 units for standard specs. No MOQ for custom projects—contact us for details.

Contact Us

📧 Email: info@sxqinsteel.com

Trusted by industrial leaders worldwide, our ASME B18.31.1M Bolts are your solution for durable, compliant fastening. Let’s engineer reliability together.

Learn about our latest products and discounts through SMS or email