Because they offer better pressure resistance, corrosion protection, and long-term reliability, AWWA C207 Class D flanges are used in municipal water systems for wastewater control and drinking water distribution. The AWWA C207 Class D flange standard makes sure that performance is consistent in a range of environmental conditions. This makes it the top choice for water authorities and infrastructure contractors who want reliable pipeline connections that meet strict city standards and operational needs.

Understanding AWWA C207 Class D Flanges: Specifications and Standards

The American Water Works Association (AWWA) created the C207 standard to make sure that there are clear rules for waterworks flanges used in city settings. This standard outlines the exact size, material, and performance needs that must be met for water transportation systems to work properly.

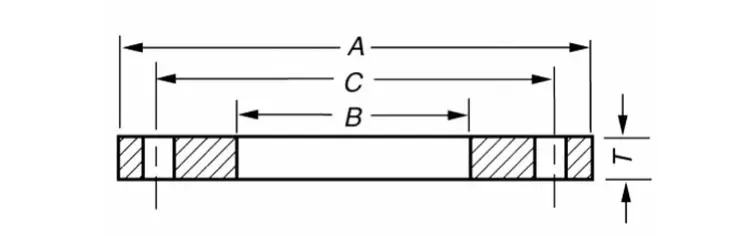

Technical Specifications and Dimensional Requirements

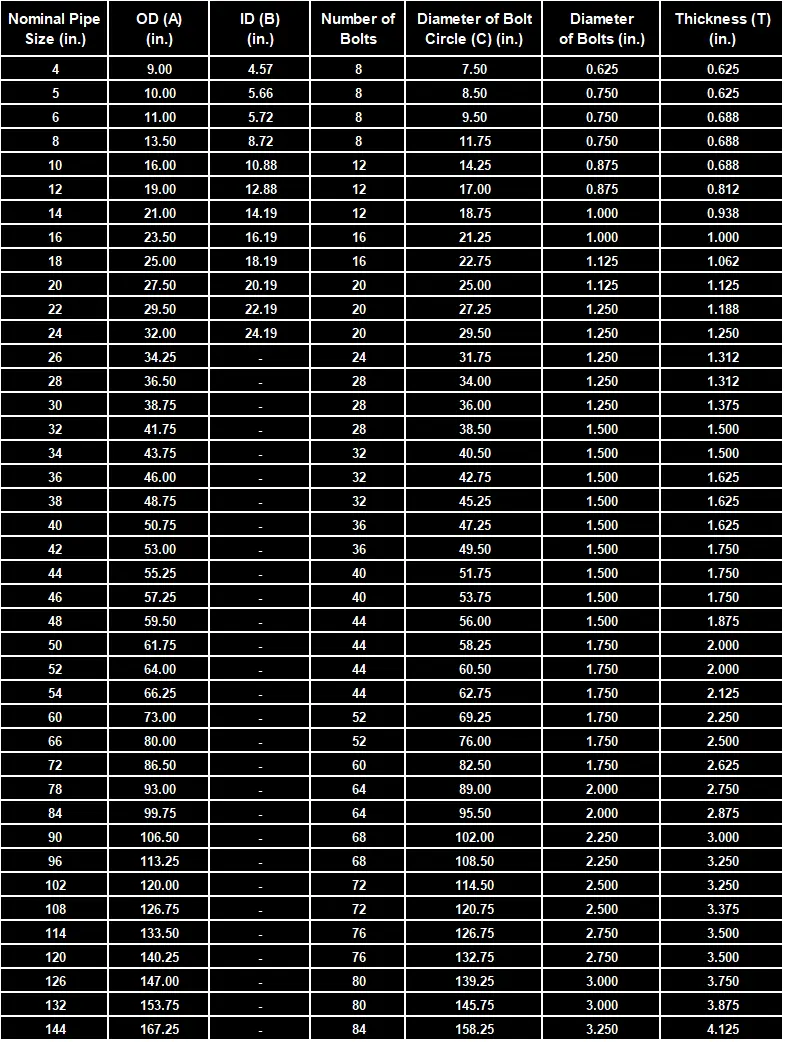

The AWWA C207 standard says that Class D flanges must be designed in a certain way so that they are not confused with flanges from other classes. These flanges can handle pressures from 175 to 250 PSI, so they can be used in water transport networks where the pressure is very high. The standard includes sizes with diameters from 4 inches to 144 inches, which makes it easier to fit different kinds of pipelines.

The dimensional accuracy in AWWA C207 makes sure that the pieces fit and line up correctly with steel water pipes. This makes the fitting easier and lowers the chance of having leaks. Flange thickness, facing measurements, and bolt patterns are carefully spelled out so that there is uniformity across projects and makers.

Material Composition and Coating Options

AWWA C207 Class D flanges use different materials to meet a range of environmental and operating needs. Carbon steel grades A105 and A36 are often used, as well as stainless steel grades A182 F304 and F316, which are better at resisting rust. These materials keep the structure intact so they can handle the pressure from fluids without breaking down because of the chemicals in the water.

Protective coats are very important for making flanges last longer. Hot-dip galvanizing, epoxy coatings, and fusion-bonded epoxy processes keep things from rusting in places that are bad for metal. These coating systems are especially useful for protecting structures in wastewater situations where hydrogen sulfide and other harmful chemicals can make materials break down faster.

Why AWWA C207 Class D Flanges Are Preferred in Municipal Water Pipelines?

Due to a number of strong benefits that help make the system more reliable and lower the cost of running it, water companies always choose Class D flanges for their public works projects.

Superior Pressure Handling and Structural Integrity

A lot of the time, municipal water systems have to deal with very high hydraulic pressures, which is especially true in places with tall buildings and in pump station discharge lines. In these difficult settings, Class D flanges do a great job of keeping the seal tight, even when there are changes in pressure and quick hydraulic changes that happen a lot in water systems.

These flanges are built strong so that they can be safely used without worrying about failure. Water officials value this dependability because it means that service won't be interrupted for thousands of customers, and they won't have to pay a lot of money to fix pipes or damage people's property.

Long-Term Durability and Maintenance Benefits

AWWA C207 Class D pipe flanges are designed with life in mind rather than saving money on the first purchase. These flanges usually need very little upkeep and last for decades. This helps city operators stay within their budget.

The corrosive quality of treated water and wastewater is something that material selection and coating systems take into account. The standard's focus on resistance to corrosion means that things don't have to be replaced or fixed as often, which lets utility companies use their resources on other important building needs.

Compatibility with Existing Infrastructure

In the past few decades, many city water systems have changed by adding different kinds of pipes and flanges. Class D flanges work very well with steel pipelines that are already in place. This makes it easier to add on to or improve the system without having to make a lot of changes to the network that is already there.

Comparing AWWA C207 Class D Flanges with Alternatives: Making the Right Choice

Understanding the differences between flange standards helps buying teams make good choices that take performance needs and budget into account.

Class D versus Class E Flanges

The AWWA C207 standard covers both Class D and Class E flanges, but they are used for different purposes. Class E flanges usually deal with uses that have less pressure. They might have different ways of doing bolts or measurements. Class D flanges have better strength and higher pressure ratings, which makes them a better fit for major transmission lines and areas with high-pressure distribution.

The pressure-handling abilities and assembly needs of these classes are directly affected by their material thicknesses and bolt configurations. When choosing between these choices, engineering teams must keep in mind safety factors and system operating pressures.

AWWA C207 versus ANSI Standards

ANSI flanges are used a lot in industry, but they might not have the exact features that city water systems need. AWWA C207 flanges are made for water and wastewater uses. Their design takes into account water chemistry, pressure cycling, and environmental exposure.

These standards have different material and testing needs. AWWA C207 focuses more on resistance to corrosion over time and stability of dimensions under thermal cycle conditions that are common in water distribution systems.

Procurement Insights for AWWA C207 Class D Flanges

To successfully get waterworks flanges, you need to know about the quality standards, market dynamics, and supplier skills that affect the budgets and timelines of projects.

Supplier Selection and Quality Assurance

Looking at a supplier's manufacturing skills, quality certifications, and history with municipal projects can help you figure out if they're qualified. ISO 9001 certification shows basic quality management, and AWWA compliance testing and other certifications show special skill in making waterworks goods.

Quality validation should have proof of material certificates, reports of dimensional inspections, and records of coating thickness. These quality steps make sure that the work meets the project's requirements. This lowers the chance of having to install in the field, which can cause delays in finishing the project.

Pricing Factors and Lead Time Considerations

AWWA C207 Class D pipe flanges' prices depend on a number of things, such as the cost of materials, the size and finish needed, and how many flanges are ordered. Buying in bulk can save a lot of money, especially for big jobs that need a lot of different sizes and types of flanges.

For normal setups, lead times are usually between 15 and 30 days, but custom specs might mean longer lead times. Planning buying activities early in the project helps avoid critical path delays and lets you check the quality before installation starts.

Installation Best Practices and Maintenance Tips for AWWA C207 Class D Flanges

In city water systems, proper installation and regular upkeep greatly affect the long-term performance of flange connections.

Installation Procedures and Common Challenges

To make sure that flange joints don't leak, you need to be careful about how the surfaces are made, which gasket is used, and how the bolts are tightened. The surface check should make sure that the finish is right and there is no damage that could weaken the seal. The material used for the gasket has to work with the water pressure and chemistry.

Bolt tightening uses certain torque patterns to make sure that the gasket is evenly compressed and the flange does not bend. Cross-pattern tightening in several stages helps get the right setting. This keeps stress from building up in one place, which can cause early failure.

Preventive Maintenance and Inspection Protocols

Regular inspection plans help find problems before they cause the system to fail. Just looking at the coating, the bolts, and the gasket can let you know early on when upkeep is needed. Finding leaks around flange joints should be a part of regular system check-ups.

Coating touch-ups and re-tightening the bolts may need to be done every so often, especially during the first service time as gaskets settle and thermal cycling happens. Keeping detailed records of maintenance work helps find the best times to do inspections and spot trends that might show there are problems with the whole system.

QinSteel: Your Trusted Partner for Municipal Water Infrastructure

Xi'an QinSteel has become a top maker and worldwide supplier of AWWA C207 Class D flanges. The flanges are used by city water departments and building contractors in North America, Europe, Africa, and Southeast Asia. Having made flanges for twenty years means we have the experience to take on a wide range of projects around the world, from water systems for cities to huge plants that turn seawater into drinking water.

Comprehensive Product Range and Customization Capabilities

Our AWWA C207 Class D flanges come in steel ring and blind styles. They are made from high-quality materials like A105, A350 LF2, A36, and many different types of stainless steel, such as A182 F304, F316, and duplex alloys F51, F53, and F55. We are able to meet the needs of different applications while still following AWWA standards thanks to this wide range of material choices.

From 4 inches to 144 inches, there are all the sizes that city water pipelines need. No matter if you need standard setups for distribution networks or flanges with big diameters for main transmission lines, our manufacturing can meet the needs of your project. Both the raised face (RF) and flat face (FF) choices can be used in a variety of ways to make sure they fit with the pipelines that are already in place.

Quality Assurance and Rapid Delivery

Our GMP-certified factory keeps a close eye on the production process to make sure everything is high quality. Before shipping, each plate is checked for dimensions, hydrostatically tested, and checked for surface quality. If you meet the AWWA, ANSI, ISO 9001, CE, and WRAS standards, you won't have to wait during the tender filing and approval processes.

We can send bulk orders in 15 to 30 days because we have more than 10,000 tons of raw materials on hand and efficient ways of making goods. Our OEM/ODM services let you change a lot of different things, like bolt patterns, thickness, and protective coatings. Our engineering support can give you a price within 72 hours of getting your technical drawings.

Conclusion

AWWA C207 Class D flanges are trusted by city water systems because they can handle pressure, protect against rust, and stay reliable over time. These specialized parts are made with care to deal with the specific problems of water distribution and garbage management. They do this by using carefully thought-out materials, protective coatings, and exact standards for size. Municipal operators and ratepayers count on the money spent on good flanges because they lower maintenance costs, make the system last longer, and make it more reliable. As the needs of our infrastructure keep growing, choosing flange options that are known to work becomes more and more important for long-term water management and protecting public health.

FAQs

How are AWWA C207 Class D flanges not like regular industrial flanges?

AWWA C207 Class D flanges are designed to be used in city water and wastewater systems. They have better resistance to corrosion, are made to fit perfectly on water pipes, and can handle the right amount of pressure for these systems. Not like regular industrial flanges, these are made with materials and finishes that can handle water chemistry and work well in city settings for decades.

Can AWWA C207 Class D flanges be used in water treatment plants for uses that have to deal with high pressure?

Yes, Class D flanges can handle pressures up to 250 PSI, so they can be used in high-pressure situations like pump discharge lines, main transmission pipes, and piping systems for treatment plants. The strong build and exact manufacturing tolerances make sure that it works well even when the pressure changes, which is typical in citywide water systems.

How do the choices of materials impact the length of AWWA C207 Class D flanges' lifespans?

The choice of material has a big effect on how long flanges last and how much they need to be maintained. Carbon steels, like A105, are very strong and cheap for normal uses. Stainless steels, like F316, fight corrosion better in harsh conditions. No matter what the base material is, protective coatings like hot-dip galvanizing or epoxy systems can make the service life longer, especially in wastewater or coastal situations where the risk of corrosion is higher.

Partner with QinSteel for Your Municipal Water Infrastructure Needs

QinSteel offers dependable AWWA C207 Class D flange solutions with full quality guarantee and shipping options to meet every need. As a well-known maker with decades of waterworks experience, we know how important these parts are to the stability of public infrastructure. Our global supply chain makes sure that project sites around the world get their orders on time, and our technical team gives expert advice on choosing the best flange for your needs. Have a great time on your next water infrastructure job, and see how the difference is made by quality engineering and customer-focused service. If you want to talk about your AWWA C207 Class D flange supplier needs with us, you can email info@sxqinsteel.com. Here's why local governments rely on our most important infrastructure options.

References

American Water Works Association. "AWWA C207-22 Standard for Steel Pipe Flanges for Waterworks Service." Denver: AWWA, 2022.

Thompson, Robert J. "Materials Selection for Municipal Water Infrastructure: A Comprehensive Analysis of Flange Performance in Corrosive Environments." Journal of Water Infrastructure Engineering, Vol. 48, No. 3, 2023.

National Association of Water Companies. "Best Practices for Municipal Pipeline Component Procurement and Installation." Washington: NAWC Technical Publications, 2022.

Chen, Maria L., and David K. Patterson. "Comparative Study of Waterworks Flange Standards: Performance Analysis in North American Municipal Systems." Water Management Technology Review, Vol. 15, No. 2, 2023.

International Water Association. "Global Standards for Water Distribution System Components: Implementation Guidelines for Developing Infrastructure." London: IWA Publishing, 2022.

Stevens, Michael A. "Economic Analysis of Flange Selection in Large-Scale Water Infrastructure Projects." Municipal Engineering Quarterly, Vol. 29, No. 4, 2023.