- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Blink Flanges

Blink Flanges: Precision Pipeline Solutions for Demanding Industries

When reliability matters in high-pressure systems, Blink Flanges deliver unmatched performance. As a leading manufacturer with 15+ years of expertise, we specialize in ASME, API, and EN-certified flanges trusted by oil refineries, chemical plants, and water treatment facilities worldwide. Our products combine rigorous quality control, global compliance, and scalable production to meet your project’s exact needs—whether you’re sealing a ½" laboratory line or a 144" offshore pipeline.

Engineered for Extreme Conditions

The products are precision-machined connectors designed to maintain integrity under pressures up to CLASS 2500 and temperatures ranging from -196°C to 800°C. Available in carbon steel, stainless steel (304/316/L), duplex, and super duplex materials, they’re built to resist corrosion, erosion, and stress cracking in aggressive environments like sour gas processing or marine installations.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Why Industries Choose Our Blink Flanges?

1. Corrosion Defense

Choose from 15+ materials including A350 LF2 for cryogenic applications or F55 super duplex for seawater resistance. All flanges undergo PMI testing to verify alloy composition.

2. Zero-Leak Guarantee

RTJ, RF, or FF facings are machined to 125-250 µin Ra smoothness, ensuring perfect seal alignment with gaskets and valves.

3. Rapid Customization

Need non-standard bore sizes? Require PTFE coating? Our OEM team can prototype custom Blink Flanges in 72 hours.

4. Global Compliance

Pre-certified with ASME Section IX, PED 2014/68/EU, and NACE MR0175—accelerating your project approvals.

Trusted in Critical Applications

- Oil & Gas: Wellhead connections, compressor stations

- Chemicals: Reactor vessel nozzles, acid transfer lines

- Water: Desalination plant intake systems

- Power: Steam turbine tie-ins

Quality Assured, Delivery Guaranteed

Every flange undergoes three checks:

1. Ultrasonic Testing: Detects subsurface defects

2. Dimensional Scan: Verifies ±0.1mm tolerance

3. Coating Inspection: Ensures 8-mil DFT protection

With 5,000+ tons of raw material in stock and 50 CNC machines, we ship 95% of orders within 30 days—packed in climate-controlled crates with ISO 2859-1 inspection reports.

Quality Control

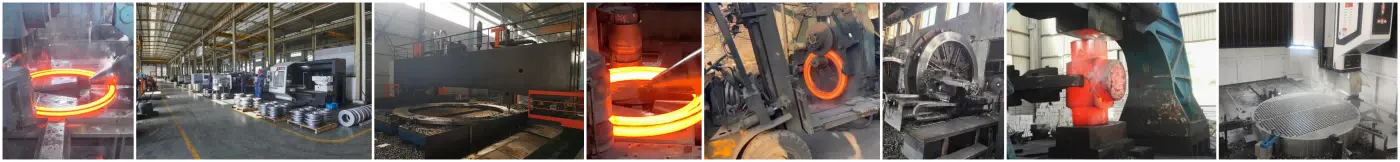

Factory Equipment

Shipping Packaging

FAQs: What Buyers Ask

Q: Can you match legacy flange designs from discontinued suppliers?

A: Yes! Send drawings for reverse-engineering.

Q: Do you provide traceable material certificates?

A: Full MTCs with heat numbers included.

Q: What's the MOQ for custom products?

A: Just 10 units for prototyping.

Q: How are flanges protected during ocean shipping?

A: VCI paper + desiccant capsules + steel-strapped pallets.

Contact Us

Email info@sxqinsteel.com for Blink Flanges:

- Same-day quotes with volume discounts

- Free material selection guide

- Live factory tour appointments

Serving ExxonMobil, Shell, and 200+ global partners since 2008.

Learn about our latest products and discounts through SMS or email