A335 P11 pipes are very important in industry when there are high temperatures. They work very well in power generation, petrochemical processing, and oil and gas activities. This chromium-molybdenum alloy steel pipe works well in places where regular carbon steel doesn't, and it can function at temperatures up to 600°C (1112°F). A335 P11 pipe is important for practical safety and longevity in steam lines, boiler systems, heat exchangers, and refineries. It has great oxidation resistance and creep strength.

Understanding A335 P11 Pipe: Specifications and Properties

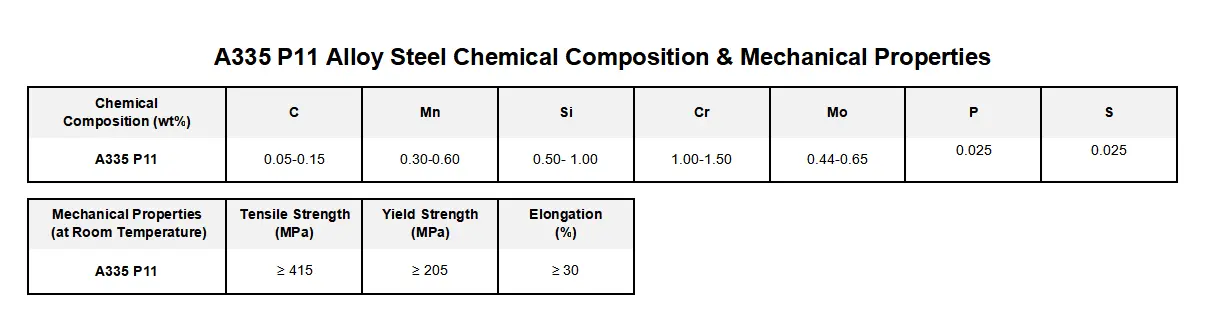

The A335 P11 pipe is a seamless alloy steel product that was designed for use in high-temperature conditions. This pipe was made according to ASTM A335 standards. It has chromium (1.00% to 1.50%) and molybdenum (0.44% to 0.65%), which make it much stronger and better able to fight corrosion than carbon steel options that are made in a more traditional way.

Chemical Composition and Mechanical Properties

The makeup of P11 alloy steel gives it very useful strong properties for tough working conditions. These pipes can handle a lot of heat and pressure. Their yield strength is 205-275 MPa and their tensile strength is 415–585 MPa. The chromium helps prevent oxidation and the molybdenum helps with creep strength at high temperatures. Heat processing methods, like normalizing at 900-950°C, make the material more efficient for better performance and stop embrittlement during service.

Size Range and Manufacturing Standards

These pipes can meet a range of project needs because they come in outer sizes from 1/4" to 24" (13.7-610 mm) and with wall thicknesses from Schedule 5s to XXS. You can choose lengths from 1 to 12 meters, and lengths can be made to fit certain needs. For projects that are worldwide, following the ASME B36.10/10M and EN 10216-1/10216-2 standards makes sure that the dimensions are right and the quality is the same. The seamless construction gets rid of welded parts that could weaken the structure under pressure.

Key Applications of A335 P11 Pipe in Industry

Power plants use A335 P11 pipes a lot in boiler systems, superheaters, and steam transport networks that have to work at high temperatures for long periods of time. These pipes are important to the petroleum industry because they are used for processing units, heat exchangers, and catalyst regeneration systems that have to work in very harsh conditions where there are high temperatures and materials that can damage the pipes.

Power Plant Applications

P11 pipes are used in very important systems like main steam lines, reheat piping, and economizer circuits in thermal power plants. Nuclear plants use these pipes in steam engines and secondary cooling systems where safety and dependability are very important. The pipes can stay structurally sound at temperatures over 500°C, which makes them necessary for efficient energy conversion.

Oil & Gas Sector Usage

Refineries use A335 P11 pipes in systems for catalytic cracking, crude distillation, and hydrotreating, all of which are ways of handling hydrocarbons at very high temperatures. Upstream activities use these pipes in thermal processing tools and better oil recovery systems. The pipes don't break down in sulfur and stay strong under the repeated temperature changes that are usual in refinery operations.

Chemical Processing Applications

It is very important that P11 pipes are used in chemical plants for systems that control temperature and prevent rust. These pipes are used in systems that make ammonia or process urea at fertilizer production plants. The pipes can be counted on to work in harsh chemical settings because they are resistant to hydrogen embrittlement and stress corrosion cracking.

Comparing A335 P11 Pipes with Alternatives: Making an Informed Choice

To choose the right material for pipes, you need to know how well they work and how much they cost. A335 P11 seamless pipes are a middle-ground choice between carbon steel and higher-alloy options. They work well in applications with moderate to high temperatures.

P11 versus P22 Comparison

A335 P22 pipes can work at temperatures as high as 650°C because they have more chromium (2.25%) and molybdenum (1.00%) than P11 pipes. But P11 pipes are cheaper for uses that don't need to be able to handle very high temperatures. P11 works well for most power plants and refineries. It also welds more easily and costs less than P22.

Alloy Steel versus Stainless Steel Analysis

While stainless steel lines are much better at resisting corrosion, they are also much more expensive than P11 alloy steel. P11 pipes are great at handling high temperatures and thermal transfer when corrosion isn't too bad. P11 has less nickel in it, which lowers the cost of the material and keeps the performance good enough for most commercial uses. Stainless steel is only needed when there is a lot of rust.

Procurement Essentials - Finding and Buying A335 P11 Pipes

When you buy something, you need to work with qualified makers who have strict quality standards and give you all the paperwork you need. Traceability of materials, testing certifications, and adherence to global standards make sure that project requirements are always met.

Supplier Selection Criteria

ISO 9001, API, and ASME are all signs that A335 P11 pipe suppliers know how to make good pipes. Material test papers (EN 10204 3.1/3.2) back up claims about a material's chemical makeup and its mechanical properties. To make sure the quality is high, suppliers should give a report on mill tests, proof of heat treatment, and the results of tests that don't damage the object.

Pricing Factors and Lead Times

The price of pipe varies based on its width, how thick its walls are, how long it needs to be, and how many pipes are ordered. Changes in the market that affect the prices of chromium and molybdenum also affect the fluctuation of prices. From inventory, standard sizes usually have shorter lead times (10–15 days), but it may take 6–8 weeks to make special sizes. Long-term deals and buying in bulk often get you better prices and make sure you always have supplies.

Installation, Maintenance, and Troubleshooting of A335 P11 Pipes

Proper installation and upkeep of a pipe system will keep it working for a long time and prevent it from breaking too early. To make sure that everything works well for as long as it is supposed to, welding methods, support design, and testing rules all need to be done by people who know what they are doing.

Welding and Installation Guidelines

P11 pipe welding needs to be heated to 150–200 °C before and after welding to ease stresses and restore the properties of the material. Qualified welding methods name the right filler materials. ER80S-B2 is usually used to match the composition. Thermal expansion must be taken into account when setting the distance between supports. At the same time, make sure that the distance does not allow for too much buildup of stress. Proper alignment and fit-up stop welding mistakes that weaken the stability of the system.

Inspection and Maintenance Protocols

If you check it often with radiography, ultrasonic tests, and a visual exam, you can find problems before they cause a failure. Thickness tracking keeps an eye on how fast corrosion happens and predicts how much longer the service life will be. Protective coatings and rust inhibitors make pipes last longer in harsh conditions. Keeping records of maintenance and inspection tasks helps follow the rules and keeps reliability engineering programs running.

QinSteel's Premium A335 P11 Pipe Solutions

With twenty years of experience in the field, QinSteel provides complete A335 P11 seamless pipe solutions designed for very important uses at high temperatures. Our seamless manufacturing method uses advanced rotary piercing technology to make sure that the whole pipe body has the same wall thickness and better mechanical properties.

Technical Excellence and Quality Assurance

Our factory uses a strict 7-step quality procedure that includes analyzing raw materials, seamless forming, normalizing heat treatment, and full testing. Every pipe is checked for surface defects with eddy current testing, for strength with hydrostatic testing at 1.5 times the pressure it was designed for, and for thickness with ultrasound testing. This methodical way of doing things makes sure that tough industrial uses always get the same high quality and dependability.

Global Supply Chain Capabilities

QinSteel keeps important stock in distribution areas across the UAE, USA, and Singapore so that they can quickly ship materials for urgent project needs. Ready-stock items in our over 15,000-ton inventory have much shorter wait times than made-to-order items. Specialized coatings like FBE and 3LPE, changes to the dimensions of parts, and more thorough testing suited to the needs of each individual project are all part of custom engineering. Our transportation network spans the globe and helps with the smooth integration of the supply chain for projects across the globe.

Conclusion

A335 P11 pipes are a very important way to get solid performance and cost-effectiveness in high-temperature industrial settings. Knowing their details, uses, and how to get them helps people make smart choices about projects in power generation, petrochemicals, and oil and gas. These chromium-molybdenum alloy steel pipes work better than carbon steel pipes and cost less than higher-alloy pipes, making them the better choice in every way. Choosing the right suppliers, installing correctly, and following upkeep rules will make sure your system works well and lasts a long time. QinSteel's all-around A335 P11 pipe solutions use both technical skill and global supply chain knowledge to help make sure that projects in a wide range of industries do well.

FAQs

What is the safe temperature range for A335 P11 pipes?

A335 P11 pipes can easily handle temperatures from -29°C to 600°C (-20°F to 1112°F). Their ability to work over a wide range of temperatures makes them good for power plant steam systems, refinery processing units, and petrochemical uses that need to be able to handle high temperatures for a long time.

When used in high-temperature situations, how does A335 P11 stack up against carbon steel?

A335 P11 is much better than carbon steel in high-temperature settings because it has chromium and molybdenum, which make it stronger against creep, rust, and temperature changes. Carbon steel quickly loses its strength at temperatures over 400°C, but P11 stays strong even at temperatures up to 600°C.

When I buy A335 P11 pipes, what approvals should I look for?

For example, compliance with ASTM A335, approval stamps from ASME, ISO 9001 quality management certification, and API licensing are all important qualifications. Also, ask for mill test papers (EN 10204 3.1/3.2) and paperwork that shows where the material came from to make sure the work is done correctly and follows the rules.

Partner with QinSteel for Your A335 P11 Pipe Requirements

With twenty years of experience in the field, QinSteel is ready to help you with your high-temperature piping needs using top-quality A335 P11 pipe options. No matter if you need normal sizes or custom shapes, our technical experts will help you choose the best materials for your needs. As a reliable A335 P11 pipe manufacturer, we offer a range of services, such as precise cutting, surface treatments, and speeding up shipping times to meet important project deadlines. To talk about your needs and see how dedicated we are to quality, reliability, and customer happiness, please email us at info@sxqinsteel.com.

References

American Society of Mechanical Engineers. "ASTM A335/A335M Standard Specification for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service." West Conshohocken: ASTM International, 2019.

Davis, Joseph R. "ASM Specialty Handbook: Heat-Resistant Materials." Materials Park: ASM International, 1997.

Viswanathan, Ramin, and John Shingledecker. "Life Assessment Technology for Fossil Power Plants." Palo Alto: Electric Power Research Institute, 2016.

Boyer, Howard E. "Atlas of Creep and Stress-Rupture Curves." Materials Park: ASM International, 1988.

Cerjak, Horst, and Pavel Mayr. "Creep Resistant Steels." Cambridge: Woodhead Publishing Limited, 2008.

Thurlbeck, Stephen D. "High Temperature Characteristics of Stainless Steels." Nickel Development Institute Technical Series, 1994.