In the oil and gas business, weld neck pipe flanges are very important for making sure that high-pressure pipeline systems stay connected. When these specialized tapered hub flanges are welded to pipes, they make connections that don't leak and can handle even the most extreme situations. They are necessary for important uses where safety and operating integrity can't be compromised because they are strongly built and very strong.

Understanding Weld Neck Pipe Flanges: Definition, Types, and Uses

What Is a Weld Neck Pipe Flange?

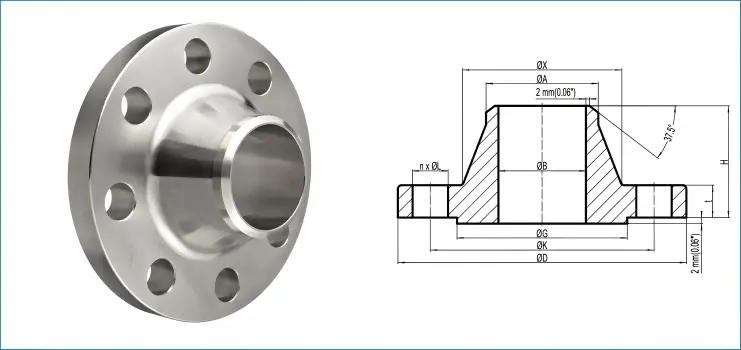

A weld neck pipe flange is made of cast steel and has a long, tapered hub that connects the flange to the pipe by going from the pipe's outer diameter to the flange's bolt circle diameter. This special design gets rid of all the sharp corners that could become stress concentration points and makes a smooth way for even stress distribution. The flange has a hole that is the same size as the inside diameter of the pipe it connects to so that the flow stays smooth.

Flanges are usually made from good materials like carbon steel (A105, A36), alloy steel (A182 F11), and stainless steel types (F304, F316, F51, F53, F55). Forging improves the grain structure of the material, giving it better mechanical qualities than casted options. QinSteel makes sure that the correctness of the dimensions and the integrity of the materials follow strict ASME B16.5 and API standards.

Types of Weld Neck Pipe Flanges

There are different kinds of weld neck flanges, each made for a certain purpose and way of installing. The business knows about these different types. Standard weld neck flanges are set up in the most usual way, with a hub length that is about the same as the pipe's nominal wall thickness. Long weld neck flanges make this hub longer so that it can be used for special welding needs or to connect to a vessel nozzle.

Lightweight weld neck flanges are great for situations where it's very important to reduce weight because they keep the strength of the structure while losing weight. When you choose between forged and cast flanges, it has a big effect on performance. Forged flanges are better at resisting wear and keeping their structure stable when they are loaded in a way that happens a lot in oil and gas operations.

Common Uses of Weld Neck Flanges in Oil & Gas

Oil and gas activities need parts that can handle very high and low temperatures, corrosive environments, and high pressure. Weld neck flanges are great for high-pressure pipeline systems where the pressure can go over 2,500 PSI. This makes them very important for wellhead connections, manifold systems, and key transfer lines. Their strong design can handle the thermal cycling that happens in systems for steam injection and refining processes that use very high temperatures.

These flanges are very important for offshore platforms because they can keep their shape even when they are used in situations that change because of wave action and thermal expansion. The safe weld makes sure that the joint won't come apart like it could with mechanical links in these difficult settings.

Key Dimensions, Pressure Ratings, and Standards for Weld Neck Pipe Flanges

Weld Neck Pipe Flange Dimensions: What You Need to Know

For good flange performance and system compatibility, dimensional accuracy is very important. Sizes from 1/2 inch to 24 inches are covered by standard measurements in ASME B16.5. For larger sizes up to 60 inches, ASME B16.47 is used. Key dimensional features are the hub length, flange thickness, diameter of the bolt circle, and key bore diameter that has to be the same as the pipe's diameter.

The hub's tapered shape meets certain physical needs. The hub gets thicker from the end of the pipe to the flange face. This controlled shape makes sure that stress is evenly spread out and the welding area is clear. For projects that are done in more than one country, European standards such as EN 1092-1 offer different ways of measuring things. This means that the measurements must be carefully checked to make sure they will work together.

Pressure Ratings and Their Industrial Significance

Pressure numbers tell you the highest working pressure that WN pipe flanges can have at certain temperatures. The ASME system uses pressure classes from 150 to 2500, and each class shows the different amounts of pressure the system can handle at different temperatures. At room temperature, Class 150 flanges can handle pressures up to 285 PSI, but Class 2500 flanges can take forces over 6170 PSI.

The selection method has to keep both operating temperature and pressure in mind because flange pressure ratings go down as temperature goes up. Oil and gas uses usually need at least a Class 600 rating to handle high-pressure work and make sure there are enough safety margins. The PN (Pressure Nominal) rating method used in European standards puts similar types of pressure ratings in groups from PN 6 to PN 400.

Relevant Industry Standards and Certifications

Following industry guidelines makes sure that flanges are safe, high-quality, and can be used with flanges from other companies. API 6A has strict rules about materials, testing, and marking for the flanges on wellhead and Christmas tree tools. ASTM standards tell flange manufacturers about the different kinds of steel grades and their material specifications, chemical makeup, and mechanical qualities.

Quality certifications show that these standards were followed by means of test certificates for materials, records on dimensional inspections, and paperwork for non-destructive testing. QinSteel uses a lot of different methods to make sure their products are high quality. For example, they use spectrometers to check that the chemicals in the metal are correct and do hydrostatic tests at 1.5 times the rated pressure to make sure the structure is sound.

Comparing Weld Neck Pipe Flange to Other Flange Types: Making Informed Choices

Weld Neck vs Slip On Flange: Strength and Application Differences

Weld neck and slip-on flanges are different in how they connect to pipes and how they spread stress. Through the tapered hub, weld neck flanges connect to the pipe's outer diameter. This forms a single metal path that spreads the stress equally. Slip-on flanges slide right over the pipe and are welded at two places. This can create spots where stress builds up.

Because of this structural benefit, weld neck flanges are better for uses with high pressure and high temperature. Slip-on flanges are cheaper and easier to install, but in tough oil and gas settings, they can't handle metal wear or maintain structural strength like weld neck flanges can.

Material Selection: Stainless Steel vs Carbon Steel for Weld Neck Flanges

The cost, how well it resists rust, and how well it holds up under stress are all factors in choosing the right material. For normal use, carbon steels like A105 are a great combination of strength and cost-effectiveness. For sour gas service and exposure to seawater, though, stainless steels are better because they fight corrosion more. Duplex stainless steels (F51, F53, F55) are strong and resistant to rust, making them useful for the most difficult tasks.

Carbon steel works well for "sweet" service and dry gas uses, but stainless steel is better for places where hydrogen sulfide, chlorides, or organic acids are present.

Installation, Benefits, and Best Practices for Weld Neck Flanges in Oil & Gas

How to Install Weld Neck Pipe Flanges Correctly

Carefully getting ready for both the flange hub and the end of the pipe is the first step in doing it right. Following the welding procedure specs, the pipe needs to be cut square and beveled. During fit-up, the flange face must stay perpendicular to the pipe axis and keep the right gap spacing for full weld penetration.

Qualified welding process specifications (WPS) that take into account the grades, thickness, and service conditions of the material must be followed when welding. Some common mistakes made during installation are not getting the fit just right, using the wrong welding settings, and not doing enough post-weld heat treatment when it is needed. These mistakes can damage the structure of the joints and cause them to fail in service before their expected time.

Key Benefits Driving Weld Neck Flange Adoption

WN pipe flanges are better than others because they are made and designed better. The main effects are:

- Better stress distribution: The tapered hub gets rid of sharp changes that cause stress to build up in certain areas, which extends the part's wear life when the load changes cyclically.

- Ability to handle high pressure: The strong design can take pressures up to Class 2500 (6170 PSI) without losing its leak-proof shape.

- Resistance to heat: Forged construction holds up to very high and very low temperatures, from cryogenic temperatures to 1500°F, based on the material chosen.

- Longer service life: Better metallurgy and stress distribution lead to longer operating life with less need for maintenance.

These benefits lead to less downtime, lower maintenance costs, and better safety margins in important oil and gas uses.

Procurement Guide: Buying Weld Neck Pipe Flanges for Oil & Gas Projects

Where to Buy: Trusted Suppliers and Manufacturers

It is important to look at a supplier's manufacturing capabilities, quality processes, and experience in the business when choosing one that is reliable. Reputable manufacturers consistently deliver on their promises, use ISO 9001 for quality control, and have API Q1 and ISO 9001 certifications. QinSteel's 20 years of experience in the business and GMP-certified facility show buyers what they should expect from good suppliers.

If a project needs special materials, non-standard sizes, or unique facing designs, it is important to have OEM and custom manufacturing options. The seller can fully trace materials and provide detailed testing records, which guarantees that the project specifications and rules are followed.

Pricing Overview and Bulk Ordering Tips

Flange prices depend on the size, pressure number, and material grade. It's common for carbon steel flanges to be 30–50% cheaper than similar stainless steel ones. On the other hand, flanges made of rare alloys may be 300–500% more expensive than those made of more common metals. Class 150 flanges are the cheapest choice, and costs go up steadily with higher pressure levels.

Ordering in bulk can cut the cost of each item by 15% to 25% while making sure that the quality and shipping schedules stay the same. Early procurement planning helps suppliers make the most of their production schedules and material sourcing. This leads to better prices and shorter lead times for project completion.

Xi'an QinSteel: Your Trusted Weld Neck Pipe Flange Manufacturer

Xi'an QinSteel Trading Co., Ltd is a top manufacturer and seller of high-performance weld neck pipe flanges. They serve the oil and gas industries with quality and reliability that never wavers. Our wide selection of products includes many different sizes (from ½" to 60"), pressure grades (from Class 150 to Class 2500), and face types (RF, FF, RTJ, M&F, and T&G).

We make CNC machining and strict quality control part of our modern production process so that every flange meets or goes beyond global standards like API 6A, EN 1092-1, and ASME B16.5. With a 2,000-ton stock of raw materials and efficient ways of making things, we meet strict quality standards and send large orders in 15 to 20 days.

Quality assurance is the most important part of our work. It includes a lot of different tests, like checking the chemical makeup with an analyzer, verifying the dimensions with laser scanning, and testing in hydrostatic pressure at one and a half times the rated pressure. Our promise to do great work has won the trust of partners around the world, including in the Americas, Africa, Europe, and Southeast Asia.

Conclusion

For tough oil and gas uses where pressure, temperature, and safety needs are higher than what standard flange types can handle, weld neck pipe flanges are the best choice. They are important to pipeline systems because they are better at spreading out stress, can handle high pressure, and last a long time. Engineers and procurement professionals who know about technical specifications, how to install equipment, and how to buy what they need can make choices that guarantee the success of their projects and the reliability of their operations.

FAQs

Why are weld neck pipe flanges the best choice for oil and gas uses with high pressure?

Weld neck flanges have a tapered hub shape that spreads stress evenly across the connection. This stops stress concentration spots that could cause failure. When this design is used with forged construction, they can handle pressures up to Class 2500 (6170 PSI) and stay leak-proof even when conditions are high.

Can slip-on or threaded flanges be used in place of weld neck flanges?

No, these flange types can't be used in place of one another because they join and handle pressure in different ways. Weld neck flanges are stronger than slip-on flanges, which have lower pressure levels and are easier to weld. Each kind has its own unique uses that depend on pressure, temperature, and how it needs to be set up.

How can I make sure that a weld neck pipe flange supplier's quality certificates are real?

Make sure that your suppliers have the right credentials by looking at their ISO 9001 quality management certification, their API Q1 monogram (if they work with oil and gas), and their material test certificates that show the chemical makeup and mechanical features of the materials. If you ask for it, honest suppliers will give you full traceability paperwork and records of third-party inspections.

Contact QinSteel for Premium Weld Neck Pipe Flanges

Are you ready to find solid weld neck pipe flanges for your next job? QinSteel has a full range of solutions at great prices, with fast delivery and expert technical help. Our skilled team offers personalized prices based on your exact needs to make sure your oil and gas applications run as well as possible. Our OEM/ODM services provide perfectly planned answers that meet the most difficult requirements, whether you need standard setups or one-of-a-kind designs. To talk about your needs for a weld neck pipe flanges provider and to see how QinSteel's quality and service are different, email us at info@sxqinsteel.com.

References

American Society of Mechanical Engineers. "ASME B16.5: Pipe Flanges and Flanged Fittings: NPS 1/2 Through NPS 24 Metric/Inch Standard." ASME Press, 2020.

American Petroleum Institute. "API Specification 6A: Specification for Wellhead and Christmas Tree Equipment." 21st Edition, API Publishing Services, 2019.

Bickford, John H. "Gaskets and Gasketed Joints, Second Edition." CRC Press, 2016.

Escoe, Keith A. "Piping and Pipeline Assessment Guide Volume 1: Piping Fundamentals, Codes, and Standards." Gulf Professional Publishing, 2018.

Singh, Kanchan. "Pressure Vessel Design Manual, Fifth Edition." Butterworth-Heinemann, 2018.

Nayyar, Mohinder L. "Piping Handbook, Eighth Edition." McGraw-Hill Education, 2019.