- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

AWWA C207 Class D Flange

AWWA C207 Class D Flange Manufacturer & Global Supplier

Trusted by municipal water authorities and infrastructure contractors worldwide, Xi’an QinSteel specializes in high-volume production of AWWA C207 Class D Flanges designed for waterworks, sewage systems, and large-scale pipeline projects. With GMP-certified manufacturing and just-in-time inventory, we deliver compliant, durable solutions tailored to your project needs.

What Are AWWA C207 Class D Flanges?

The products are engineered for secure, leak-proof connections in high-pressure water transmission and wastewater systems. These steel ring and blind flanges meet strict AWWA C207 standards, ensuring durability in corrosive environments and compatibility with steel pipelines from 4" to 144". Ideal for municipal projects, they’re built to withstand pressures up to 275 PSI while offering RF/FF facing options.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN 15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Why Our Flanges Stand Out?

Built for Demanding Water Systems

- AWWA C207 Class D Certified: Guaranteed compliance with pressure, dimension, and material standards.

- Corrosion-Resistant Options: Choose hot-dip galvanized or epoxy-coated finishes for wastewater/saline environments.

- Broad Size Range: From 4" for localized networks to 144" for main supply lines.

- Dual Facing Flexibility: RF (Raised Face) or FF (Flat Face) configurations to match existing pipeline setups.

Speed Meets Precision

- Fast Turnaround: 15–30 days for bulk orders, backed by 10,000+ tons of raw material stock.

- OEM/ODM Support: Customize bolt patterns, thickness, or coatings—submit your drawings for a quote within 72 hours.

Applications

- Municipal water distribution networks

- Pump stations in irrigation systems

- Valve assemblies for wastewater treatment plants

- Infrastructure upgrades and retrofits

Why Partner With Xi'an QinSteel?

Expertise You Can Trust

- 20+ Years in Flange Manufacturing: 500+ global projects completed, from North American utilities to Middle Eastern desalination plants with AWWA C207 Class D Flange.

- End-to-End Compliance: Pre-certified with AWWA, ANSI, ISO 9001, CE, and WRAS—no delays during tender submissions.

- Rigorous Quality Checks: Every flange undergoes dimensional inspection, hydrostatic testing, and surface quality audits.

Hassle-Free Global Logistics

- Damage-Proof Packaging: Waterproof pallets with steel strapping.

- Regional Warehouses: 7-day delivery to NA, EU, and MENA regions.

Quality Control

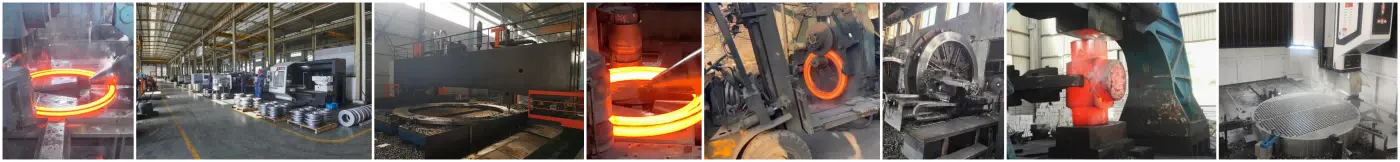

Factory Equipment

Shipping Packaging

FAQ

Q: Can you provide flanges for non-standard pipeline configurations?

A: Yes! Our engineering team adapts dimensions, bolt holes, and coatings to your specs.

Q: What certifications do your products hold?

A: All flanges include AWWA/ANSI compliance. CE, WRAS, and UL certifications are available upon request.

Q: What's the lead time for 1,000 units?

A: Typically 15–20 days. Contact us for expedited options.

Q: Do you support small orders for repairs?

A: Absolutely—no strict MOQ.

Q: How do you ensure corrosion resistance?

A: We offer hot-dip galvanizing (up to 86μm thickness) or epoxy coatings per ASTM A123.

Contact Us

Ready to Streamline Your Water Project?

Email: info@sxqinsteel.com

Request a quote for AWWA C207 Class D Flanges today—samples and technical drawings available!

Learn about our latest products and discounts through SMS or email