- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What to do if Socket Weld Flanges Show Signs of Leakage?

Nov 24 2025

If you notice signs of leakage in socket weld flanges, it's crucial to address the issue promptly to prevent further damage and ensure system integrity. The first step is to shut down the system safely. Next, carefully inspect the flange for visible damage or wear. Replace the aging gasket with a new, high-quality one suitable for your application. Before reinstalling, thoroughly check the welding joint for any gaps or imperfections. If necessary, consult a qualified welding professional to repair or reinforce the joint. Once repairs are complete, carefully reassemble the flange connection, ensuring proper alignment and tightening. Finally, perform a pressure test to verify the leak has been successfully resolved before returning the system to normal operation.

Understanding Socket Weld Flanges and Common Causes of Leakage

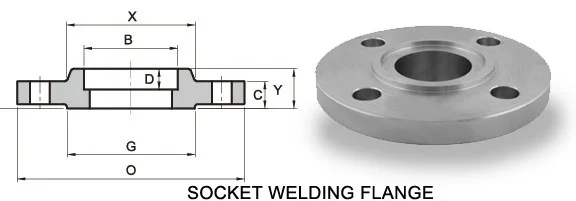

What are Socket Weld Flanges?

Socket weld flanges are crucial components in piping systems, particularly in high-pressure and high-temperature applications. These flanges feature a socket, or recessed area, into which the pipe is inserted and welded. This design provides a strong, leak-resistant connection that can withstand severe conditions in industries such as oil and gas, chemical processing, and power generation.

Common Causes of Socket Weld Flange Leakage

Several factors can contribute to leakage in socket weld flanges:

- Improper installation or welding techniques

- Thermal cycling and material fatigue

- Corrosion or erosion of the flange or pipe material

- Gasket failure or degradation

- Misalignment during assembly

- Excessive vibration or mechanical stress

Understanding these potential causes is essential for effective troubleshooting and prevention of future leaks.

Signs of Socket Weld Flange Leakage

Detecting leaks early can prevent costly downtime and potential safety hazards. Look out for these signs:

- Visible fluid or gas escaping from the flange joint

- Unusual sounds, such as hissing or whistling

- Unexplained pressure drops in the system

- Corrosion or discoloration around the flange area

- Accumulation of debris or residue near the connection

Regular inspections and maintenance of socket weld flange can help identify these issues before they escalate into major problems.

Step-by-Step Guide to Addressing Socket Weld Flange Leakage

Initial Safety Measures and System Shutdown

When dealing with socket weld flange leakage, safety should always be the top priority. Follow these steps to ensure a safe working environment:

- Alert all relevant personnel about the leak and the impending shutdown.

- Implement proper lockout/tagout procedures to isolate the affected area.

- Gradually depressurize the system following established protocols.

- Allow the system to cool down if it operates at high temperatures.

- Ensure proper ventilation in the work area to disperse any residual gases or vapors.

- Don appropriate personal protective equipment (PPE) before approaching the leak site.

By following these safety measures, you create a secure environment for inspection and repair work.

Inspection and Diagnosis of the Leak

Once the system is safely shut down, conduct a thorough inspection to identify the root cause of the leak:

- Visually examine the flange and surrounding area for signs of damage or corrosion.

- Check for misalignment between the flange and the pipe.

- Inspect the welding joint for cracks, gaps, or other imperfections.

- Examine the gasket for signs of wear, compression set, or chemical attack.

- Look for any foreign objects or debris that may have compromised the seal.

- Use non-destructive testing methods like dye penetrant or ultrasonic testing if necessary.

Accurate diagnosis is crucial for determining the appropriate repair strategy and preventing future leaks.

Repair and Replacement Procedures

Based on the inspection results, take the following steps to address the leak:

- If the gasket is damaged, replace it with a new one suitable for your application.

- Clean the flange faces thoroughly to ensure a proper seal.

- If the welding joint shows signs of failure, consult a certified welder for repairs.

- Address any corrosion issues by cleaning and applying appropriate protective coatings.

- If the flange itself is damaged beyond repair, replace it with a new, high-quality socket weld flange.

- Ensure proper alignment during reassembly using alignment tools if necessary.

- Tighten bolts in a star pattern to the recommended torque specifications.

After completing the repairs, perform a pressure test to verify the integrity of the connection before returning the system to service.

Preventive Measures and Long-Term Solutions for Socket Weld Flange Integrity

Implementing a Regular Maintenance Schedule

Proactive maintenance is key to preventing socket weld flange leakage. Develop a comprehensive maintenance plan that includes:

- Regular visual inspections of all flange connections

- Periodic non-destructive testing to detect hidden flaws

- Scheduled gasket replacements based on manufacturer recommendations

- Monitoring of system parameters such as pressure and temperature

- Keeping detailed records of inspections, repairs, and replacements

By staying ahead of potential issues, you can significantly reduce the risk of unexpected leaks and extend the lifespan of your piping system.

Proper Installation and Welding Techniques

Many leakage issues can be traced back to improper installation. Ensure your team follows these best practices:

- Use only qualified welders with experience in socket weld flange installation

- Follow proper welding procedures and parameters as specified by industry standards

- Ensure proper fit-up and alignment before welding

- Implement effective quality control measures, including weld inspections

- Use appropriate filler materials compatible with the base metals

- Allow for proper cooling and stress relief after welding

Investing in proper installation techniques can save significant time and resources in the long run.

Selecting the Right Materials and Components

Choosing high-quality materials and components is crucial for long-term reliability:

- Select socket weld flanges made from materials suitable for your specific application

- Use gaskets designed for the operating conditions (temperature, pressure, and chemical compatibility)

- Consider upgrading to more corrosion-resistant alloys in challenging environments

- Ensure all components meet or exceed relevant industry standards (e.g., ASME, API)

- Work with reputable suppliers who can provide material certifications and quality assurance

By investing in quality materials and components, you can significantly reduce the likelihood of leaks and extend the service life of your piping system.

Conclusion

Addressing socket weld flange leakage requires a systematic approach that prioritizes safety, thorough inspection, and proper repair techniques. By following the steps outlined in this guide, you can effectively resolve leakage issues and minimize downtime. Remember that prevention is key – implementing regular maintenance, ensuring proper installation, and selecting high-quality materials will go a long way in maintaining the integrity of your piping system. Stay vigilant, prioritize safety, and don't hesitate to consult experts when needed. With the right approach, you can keep your socket weld flanges leak-free and your operations running smoothly.

FAQs

How often should socket weld flanges be inspected?

Regular inspections should be conducted at least annually, with more frequent checks in high-stress or corrosive environments.

Can I reuse a gasket after disassembling a socket weld flange?

It's generally not recommended to reuse gaskets, as they may have deformed or degraded during use.

What are the advantages of socket weld flanges over other types?

Socket weld flanges offer excellent leak resistance and are ideal for high-pressure, high-temperature applications.

Expert Socket Weld Flange Solutions for Leak Prevention | QinSteel

At QinSteel, we specialize in high-quality socket weld flanges designed for optimal performance and leak prevention. With 20 years of industry expertise, our comprehensive range of flanges and fittings meets international standards and caters to diverse applications. As a trusted supplier and manufacturer, we offer durable, precision-engineered products that ensure reliability in critical systems. Contact us at info@sxqinsteel.com for expert advice and solutions tailored to your specific needs.

References

ASME B16.11: Forged Fittings, Socket-Welding and Threaded

API 6A: Specification for Wellhead and Christmas Tree Equipment

Fluid Sealing Association: "Gasket Installation Procedures"

American Welding Society: "Welding Handbook, Volume 4: Materials and Applications, Part 1"

NACE International: "Corrosion in the Petrochemical Industry"

Pipe Flanges and Flanged Fittings: ASME B16.5

Learn about our latest products and discounts through SMS or email