The AWWA C207 Class D flange is an important part of waterworks and wastewater management systems. It was designed to make sure that connections stay tight in systems that move clean water, in sewage treatment plants, and in big city pipelines. These steel ring and blind flanges meet the standards of the American Water Works Association. They work well in harsh conditions and can handle pressures of up to 275 PSI in pipes from 4 inches to 144 inches across a range of sizes. These flanges make connections that don't leak, which is important for public health and safety. They are mostly made for local water agencies and people who work on infrastructure.

Introduction

The AWWA C207 Class D flange is a specialized piping part that works really well for clean water systems and is used a lot in both waterworks and commercial settings. This flange is famous for being very strong and working well with very strict clean water standards. It plays an important role in making sure that pipe joints stay intact under high pressure.

This detailed guide is meant for procurement managers, engineers, distributors, and original equipment makers. It gives them all the information they need about flange specifications, when they can be used, and how to buy them. Our goal is to help people in the water infrastructure business make smart choices when they buy things and deal with the special problems they face.

Today’s water treatment plants need parts that meet strict safety standards and keep the plants running for a long time. Because of these reasons, AWWA C207 Class D flanges have become very important in building projects in North America and other parts of the world today.

Understanding AWWA C207 Class D Flange - Specifications and Features

AWWA C207 Class D flanges are standard parts for water systems that are mostly used with ductile iron and steel pipes. These specialized flanges are very important for safety and dependability in systems that distribute drinking water, treat sewage, and move fluids for industrial purposes.

Technical Specifications and Pressure Ratings

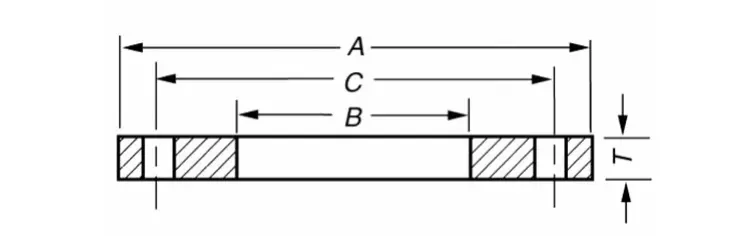

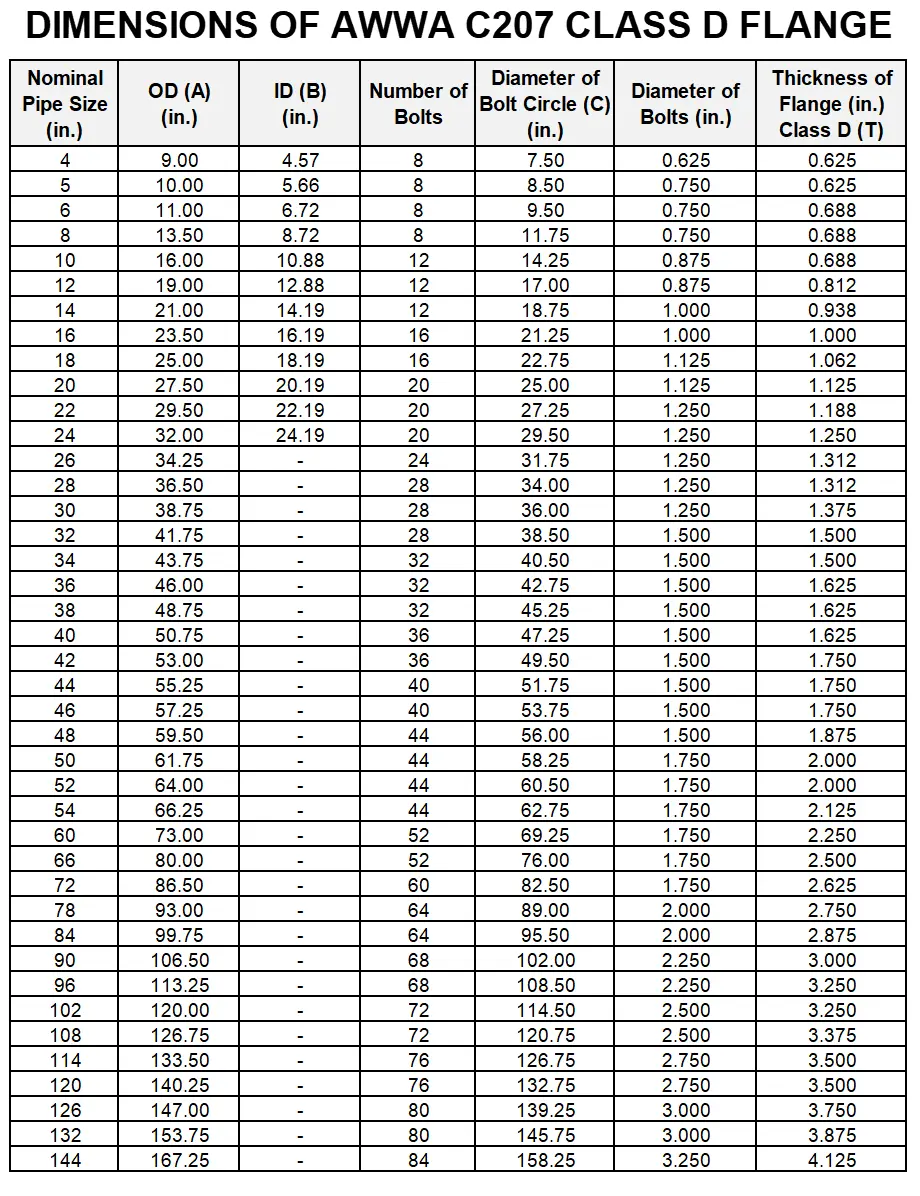

Key characteristics include standard sizes like bolt circle diameter and flange thickness, as well as pressure ratings. The pressure ratings support operations from 175 to 275 PSI. These levels of pressure can handle most of the needs of city water systems, and they also make sure that there is extra safety just in case the needs of the system change.

The measurement standards make sure that products from different companies can work together and that they all have the same performance features. Bolt patterns are based on exact rules that help the gasket close correctly and the stress spread evenly during installation.

Material Composition and Construction

A105 carbon steel, A350 LF2 for low-temperature uses, and different grades of stainless steel like A182 F304, F316, and duplex grades F51, F53, and F55 are all high-quality materials that are often used in construction. These materials are great at resisting rust, which is important for the safety of drinking water, and they can also be used in a wide range of environments.

Protective coats help things work better in harsh conditions. Hot-dip galvanization and epoxy coating provide the best corrosion protection for finishes used in wastewater and saltwater settings. In complex piping networks, the steel ring and blind flange designs allow for both through-flow and termination.

How to Choose the Right Flange for Waterworks Applications - A Decision Support Guide

Choosing the right AWWA C207 Class D pipe flanges relies on many important things, such as how compatible the pipe material is, what the operating pressure needs to be, what the environmental exposure conditions are, and what the gasket compatibility specifications are. Knowing these factors makes sure that waterworks applications run perfectly and last a long time.

Pressure Class and Material Selection

AWWA C207 Class D flanges work best with certain levels of pressure and types of pipe, but they should be carefully compared to others like Class E or ANSI flanges to make sure they're the best choice. The choice between carbon steel and stainless steel greatly affects how well the project will fight corrosion and how much it will cost.

Water chemistry, changes in temperature, and contact with harsh chemicals are all environmental factors that affect the choice of materials. Duplex stainless steels keep costs down compared to higher-alloy steels while offering better protection to rust in tough conditions.

Gasket and Bolt Compatibility

Choosing the right gasket and bolt makes sure that the whole system's sealing performance lasts for its entire operating lifecycle. Rubber gaskets made for AWWA uses seal better than metal gaskets and allow for cycles of thermal expansion and contraction.

To avoid galvanic corrosion and still get enough clamping power, the bolt material and coating must work with the flange material. The reputation of the seller, compliance with certification, and lead times are all procurement factors that are important for the smooth execution of projects and the management of budgets.

Installation and Maintenance Best Practices for AWWA C207 Class D Flange

Following the right steps for installation makes sure that water distribution systems work perfectly and avoids expensive mistakes. Following the rules protects both the system and general health, and it also makes parts last longer.

Installation Procedures and Torque Specifications

To avoid leaks and mechanical failure, professional installers must follow certain torque settings and adjustment instructions. Standard methods include the right ways to tighten bolts in star or cross patterns to make sure that the gasket is compressed evenly and the stress is spread out.

To get the best fit, centering and surface preparation are important when putting in a gasket. Making sure that flange sides are clean and smooth will stop any possible leaks. Also, making sure that bolts are properly lubricated will make sure that the right torque is used and galling doesn't happen during installation.

Troubleshooting and Maintenance Requirements

Flange misalignment and gasket deterioration are common problems that can weaken a system and lead to expensive fixes. Regular inspection methods find problems before they get worse and turn into major failures.

Flanges last longer and systems stay reliable when routine maintenance like regular inspections and quick gasket replacement are done. Flange surfaces and protective coats are safe from damage when the pipeline is properly installed and stored. This keeps the pipeline working well for its entire operational lifecycle.

Procurement Insights - Buying AWWA C207 Class D Flange with Confidence

Getting good waterworks AWWA C207 Class D pipe flanges depends on getting ISO certification and having direct factory purchase options and full technical support. Strategic buying planning makes sure that project requirements and delivery times are met while also getting the most value.

Supplier Selection and Certification Requirements

The amount of time suppliers need to deliver goods and their bulk price structures are very different from each other. This creates chances to save a lot of money by planning ahead and committing to buy a large amount. AWWA standards will still be followed by custom manufacturing services that give you more options to meet the needs of any job.

In-depth technical support, like giving thorough datasheets and talking to experts, is very helpful for making sure that flange specifications and application needs are in line with each other. This method lowers the risks involved in getting things done while also making sure that system design results are as good as possible for all kinds of project sizes.

Quality Assurance and Documentation

Comprehensive quality paperwork including material test certificates and dimensional inspection reports makes sure that the project follows the rules. When you pre-certify products with AWWA, ANSI, ISO 9001, and other related certifications, you don't have to wait for tender submissions and regulatory approvals.

Dimensional inspection, hydrostatic testing, and surface quality checks are all part of strict quality control that makes sure each batch works the same. These steps make sure that long-term reliability, warranty promises, and project success are all possible.

QinSteel AWWA C207 Class D Flange Solutions

QinSteel makes and supplies high-quality AWWA C207 Class D flanges that are designed especially for waterworks and industry around the world. Our wide selection of products includes many customization choices that are meant to meet specific engineering needs while still following all applicable global rules.

We get results because our over 20 years of experience and more than 500 projects completed around the world, from North American utilities to Middle Eastern desalination plants. Our goods are made with GMP-certified production, and we use just-in-time inventory management. Our products include steel rings and blind flanges in sizes from 4 to 144 inches, with pressure values from 175 to 275 PSI.

These are the main benefits of our AWWA C207 Class D flanges:

- A wide range of materials can be used, such as A105, A350 LF2, A36, SS 400, and high-quality stainless steels A182 F11, F304, F316, F51, F53, and F55, to meet different needs.

- Two-sided choices with raised and flat face configurations to fit current pipeline setups and gasket needs

- We can deliver large orders in 15 to 30 days, since we have more than 10,000 tons of raw materials on hand.

- Within 72 hours, you can get OEM/ODM services with unique bolt patterns, thickness requirements, and protective coatings.

These benefits clearly help local water authorities and infrastructure contractors deal with the tough procurement issues they face while also making sure they work well in the long term for demanding uses. For every production batch, dimensional inspection, hydrostatic testing, and surface quality audits are part of our quality assurance routines.

Conclusion

AWWA C207 Class D flanges are very important to today's water systems because they make sure that the pipes used for city water, sewage, and industry purposes stay connected. Understanding their specifications, right selection criteria, and installation needs helps people make smart buying choices that guarantee long-term system reliability. Strategic supplier relationships with certified makers give you access to quality goods, technical know-how, and quick customer service, which are all important for getting projects done. Choosing and correctly installing the right flange lowers maintenance costs and extends the service life of important water infrastructure uses.

FAQs

For AWWA C207 Class D flanges, what are common pressure ratings?

AWWA C207 Class D flanges are usually able to handle between 175 and 275 PSI of pressure. This makes them a good choice for most drinkable water systems and some moderate commercial uses, as well as giving a little extra safety room for changes in system pressure.

Is it okay to use AWWA C207 Class D valves in drinking water systems?

Yes, these flanges are made for drinking water systems. The materials and finishes meet strict water quality standards, protect public health, and follow the rules.

When it comes to resisting rust, how does the AWWA C207 Class D flange stack up against ANSI flanges?

When used in drinking water settings, AWWA C207 Class D flanges made of carbon steel or stainless steel with protective coatings usually resist rust better than normal ANSI flanges. This is especially true for municipal uses.

Partner with QinSteel for Your AWWA C207 Class D Flange Requirements

When you work with QinSteel on AWWA C207 Class D flanges, you can be sure that your waterworks projects will get a reliable, compliant answer from a company with twenty years of experience in the field. Our wide collection and the ability to make custom items meet a range of project needs while keeping prices low and delivery times short. To see all of our products, go to sxqsteel.com. If you want to get a detailed quote, technical datasheet, or talk to an expert about your unique needs, email us at info@sxqinsteel.com.

References

American Water Works Association. "AWWA C207 Standard for Steel Pipe Flanges for Waterworks Service, Sizes 4 In. Through 144 In." American Water Works Association, Denver, Colorado, 2018.

Smith, Robert J. "Municipal Water Distribution System Design and Construction." Water Infrastructure Engineering Journal, Volume 45, Issue 3, 2019.

Johnson, Michael P. and Davis, Sarah L. "Corrosion Resistance in Water Treatment Facility Piping Components." Journal of Water Treatment Technology, Volume 28, Number 2, 2020.

Thompson, Kevin R. "Best Practices in Waterworks Flange Installation and Maintenance." Municipal Engineering Quarterly, Volume 12, Issue 4, 2021.

Williams, Patricia M. "Material Selection Guidelines for Potable Water Distribution Systems." Water Quality and Safety Engineering, Volume 33, Number 1, 2022.

Anderson, David C. "Procurement Strategies for Water Infrastructure Components." Public Works Management Review, Volume 19, Issue 2, 2023.