Choosing the right pipe material is very important for the success of an operation when it has to deal with very high or low temperatures and pressures in industrial settings. The A335 P22 pipe is a chromium-molybdenum alloy steel that was made to work well in very hot conditions. It works great in power generation, petrochemical, and refinery activities. This seamless pipe has the best mix of thermal stability, corrosion resistance, and mechanical strength. This makes it an essential choice for important infrastructure projects. Our in-depth study focuses on business-to-business procurement managers, engineers, distributors, and OEMs who need piping that can handle temperatures up to 580°C and keep its shape even when conditions are tough.

Understanding A335 P22 Pipe Specifications and Properties

Chrome-moly alloy pipes are based on the engineered qualities and carefully balanced chemical makeup of their materials. Understanding these standards helps people make smart choices about applications that use a lot of heat in a range of industries.

Chemical Composition and Alloy Elements

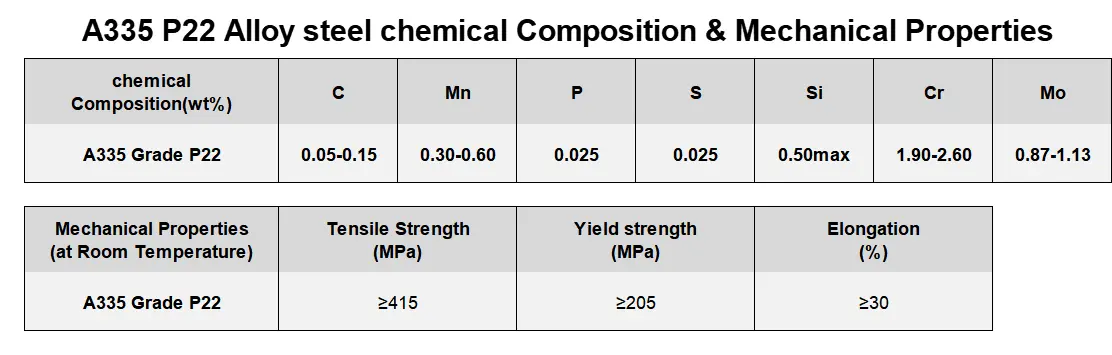

Chromium (2.0%-2.5%) and molybdenum (0.9%-1.1%) have been added to the A335 P22 pipe in carefully measured amounts. These two elements are primarily responsible for the pipe's better performance. Chromium improves resistance to rust and corrosion, and molybdenum makes metals stronger at high temperatures and resistant to creep. The amount of carbon is usually between 0.05% and 0.15%, which keeps the metal weldable and makes sure it is strong enough. Adding silicon and manganese helps with deoxidation and makes the general mechanical properties better. The carefully balanced composition makes sure that the best performance is achieved in both hydrocarbon processing settings and high-pressure steam applications.

Mechanical Properties and Heat Treatment

Our pipes without joints have a tensile strength of at least 415 MPa, and their yield strength specs meet the ASTM A335 standards. Normalization, tempering, and other heat treatments improve the grain so that it resists creep and stays stable in size. The controlled cooling rates during production ensure that the grain structure is the same all the way through the thickness of the pipe wall. These mechanical qualities allow dependable performance under long-term thermal stress without damaging the structure. From Schedule 10 to Schedule 160, different wall thicknesses can handle different pressure levels up to 3000 PSI.

Microstructure and Corrosion Resistance

Chrome-moly pipes have a ferritic-pearlitic microstructure that can stand up to oxidation and thermal cycles very well. This metallurgical structure stays stable at high temperatures and resists grain border precipitation, which can make the metal weaker. It resists corrosion better than carbon steel, especially in places where sulfur chemicals and acids are present. The alloy's make-up means that an oxide layer is formed on top of it, which stops it from breaking down any more during long periods of use.

Dimensions and Standards Compliance

To fit the needs of a variety of projects, this comes in a range of lengths and diameters. The outer diameter can be anywhere from 1/4" to 24" (13.7 mm to 610 mm), and the length can be anywhere from 1 m to 12 m. Following the standards means following the rules laid out in ASME B36.10/10M, EN 10216-1, and EN 10216-2. As part of the end preparations, a range of connection types are available, such as plain, beveled, threaded, and notched. International guidelines for dimensional tolerances make sure that the system can work with A335 P11 seamless pipes and parts that are already in place.

Comparing A335 P22 Pipe with Similar Alloys for High-Temperature Service

Choosing the right material involves carefully considering how it will work, how much it will cost, and how it will be used. Looking at the different grades of alloy makes it easier to find the best option for certain working conditions.

A335 P22 vs P11 and P91 - Performance and Usage Differences

P11 has less chromium in it (1.0%-1.5%) than P22 does, so it is weaker and easier to oxidize at high temperatures. P91 has much better resistance to creep with 8.0% to 9.5% chromium and more vanadium added to it, but it is much more expensive. P22 is a great middle-ground option for uses that need reasonable high-temperature performance. It also isn't as expensive as the more advanced grades. P11 can only work at about 500°C, but P22 works well up to 580°C, and P91 goes up to 650°C for special uses.

A335 P22 vs Carbon Steel and Stainless Steel Pipes

A106 Grade B carbon steel pipes have lower upfront costs but don't work well at temperatures above 400°C. Stainless steel types need more money to buy and may have problems with carbide precipitation at some temperature ranges, but they are much better at resisting corrosion. Chrome-moly alloy pipes are a cheap and effective choice for uses with medium to high-temperature needs. They also keep good weldability and machinability features. The financial benefit becomes important in big projects where the cost of materials affects the ability of the project to be completed.

Selecting the Best Pipe for High-Temperature Applications

The operating temperature, pressure needs, fluid makeup, and long-term cost should all be part of the selection factors. P22's ability to resist high temperatures and corrosion would help a petrochemical plant that processes fuels at 550°C. P22 pipes are great for economizers and lower-temperature superheaters in power plants that use systems with superheated steam. To find the total cost of ownership, the decision matrix should have the projected service life, installation needs, maintenance schedules, and original material cost.

Procurement Insights: How to Source Quality A335 P22 Pipe Globally

To procure successfully, you need to know about quality standards, foreign supply networks, and logistics. Strategic buying makes sure that materials are always on hand for projects, and it also helps with cost and delivery time planning.

Where to Buy: Trusted Suppliers and Manufacturers

QinSteel is one of the well-known global companies that offers approved chrome-moly alloy pipes with full quality records. ISO 9001, ASME authorization, and Pressure Equipment Directive compliance are all examples of foreign certifications that should be looked at when evaluating suppliers. The evaluation of production capacity makes sure that project timelines can be met, and the capability of expert support offers useful help in the course of choosing materials and developing specifications. Our inventory of 15,000 metric tons helps us meet the needs of quick shipping for important projects across Europe, Asia, and the Americas.

Pricing, MOQ, and Bulk Order Discounts

The cost of materials, how hard it is to make things, and desire around the world can be seen in today's market prices. Depending on the size and other details of the pipe, the minimum order quantity is usually between 5 and 10 tons. Orders over 50 tons get volume discounts, and long-term supply deals give even more discounts. To get the best results in buying, price talks should look at the overall value of the project, when it needs to be delivered, and the terms of payment. When the market is volatile, prices must be able to change so that buyers and sellers are safe from sudden changes.

Logistics, Lead Times, and Export Regulations

Standard production lead times rely on specifications and the number of items ordered, and they usually take between 15 and 30 days. Mill test certificates, material traceability reports, and compliance declarations for foreign shipping requirements are all part of export documentation. Packaging uses VCI film that prevents corrosion and wooden boxes for protection so that no damage happens during shipping in different weather conditions. When you know how customs and import rules work, you can avoid delays and extra costs when buying things from other countries.

Application Areas and Performance of A335 P22 Pipe in Industry

Chrome-moly A335 P11 seamless pipes are useful and dependable for many different kinds of industrial tasks, as shown by their performance in the real world. Understanding specific use cases helps people feel good about the choices they make about materials and how they will work.

Typical High-Temperature Applications

In power generation plants, these pipes are used in boiler economizers, low-temperature superheaters, and main steam lines where the temperature can get as high as 580°C. Petrochemical companies use them to make sure that the process piping, connections for heat exchangers, and piping systems for reactor vessels all work. Refineries use these in hydrocracking units, reformation systems, and networks for high-pressure steam. Marine uses include LNG carrier piping systems where it is very important that they are reliable and not too heavy. The material's ability to keep its mechanical properties under high heat and prevent different kinds of corrosion is useful for every application.

Advantages in Corrosion and Heat Resistance

Field performance data shows that it lasts longer than carbon steel options in places where the temperature is high. In hydrocracker uses where carbon steel had to be changed out every 7 to 8 years, a big refinery said that P22 pipes lasted 15 years. Chromium naturally resists oxidation, and molybdenum makes the material work better in settings that have sulfur in them. Better protection to corrosion and heat means that maintenance needs much less often. These benefits in performance lead to less downtime, lower maintenance costs, and better working reliability in many areas of industry.

QinSteel: Your Trusted Partner for A335 P22 Pipe Solutions

After twenty years in the business, QinSteel has become a top global provider of high-quality alloy steel pipes and complete plumbing solutions. Our promise to excellence makes our manufacturing methods and customer service always get better.

About Our Company

QinSteel is a top company that exports complete pipeline system solutions to customers in the Americas, Africa, Europe, and Southeast Asia. Our GMP-certified facility uses advanced metallurgical knowledge and responsive technical help to make sure that the best materials are chosen and installation is guided. We are committed to high quality, as shown by our EN standards compliance, ASME authorization, and NACE MR0175 approval for sour gas service. The business keeps important relationships with top steel mills and puts money into new testing tools and quality control systems.

Our A335 P22 Pipe Product Range and Custom Services

The A335 P22 pipe in our collection ranges from 1/4" to 24" in diameter, and the walls can be anywhere from Schedule 5S to Schedule 160 thick. Custom services include cutting to length, unique end preparations, and changes to heat treatment in order to meet the needs of certain projects. Quality control steps include hydraulic pressure checks, ultrasonic testing, and thorough hardness checks. Mill Test Certificates (EN 10204 3.1) are given for every shipment. OEM and ODM services follow global rules while still being able to meet your exact needs. Before making the choice to buy a lot of something, sample services let you test the material.

Supporting Your Procurement and Technical Needs

During all stages of a project, committed technical support helps with choosing materials, creating specifications, and giving advice on how to put things. Our customer service is available 24/7, so no matter what time zone our customers are in, they can reach us and get help in a variety of languages. Flexible order processing can handle different shipping times while keeping up with quality standards and paperwork needs. After-sales service includes getting advice on technical issues, making sure replacement parts are available, and providing ongoing help to build long-term relationships with customers. Competitive prices and dependable delivery help get projects done on time and within budget.

Conclusion

Chrome-moly alloy pipes are the best choice for reliable performance in tough situations in high-temperature industrial settings. When chromium and molybdenum are balanced in a mixture, they give great thermal stability, protection to corrosion, and mechanical strength while still being cheaper than high-end alloy options. Procurement managers and engineers around the world can be sure that their projects will go well because QinSteel has a wide range of products, technical knowledge, and can serve people all over the world. Because we are committed to quality, have reasonable prices, and offer quick customer service, we are the best partner for important piping applications in a wide range of industries.

FAQs

What is the hottest temperature at which A335 P22 pipes can work?

A335 P22 pipes can safely work at temperatures up to 580°C (1076°F). This makes them a good choice for power production and petrochemical services at medium to high temperatures.

What are the costs and performance levels of A335 P22 and P91, and how do they relate to each other?

P22 is very cost-effective, resists corrosion well, and has decent mechanical qualities for most uses. P91, on the other hand, is much more expensive but much stronger at high temperatures. The choice relies on the temperature needs and the budget.

Can you use A335 P22 pipes for building that is welded?

Yes, these pipes are used a lot in welded systems and are great for weldability. Following the right steps for welding and doing a post-weld heat treatment are important for keeping the mechanical properties and making sure it works in the long run.

Partner with QinSteel for Premium A335 P22 Pipe Solutions

QinSteel offers great value because of our wide A335 P22 pipe collection, knowledge of the field, and ability to get goods to people around the world. As a trusted manufacturer, we offer reasonable prices, quick delivery, and extensive technical support to make sure your high-temperature projects are successful. All of our seamless lines meet global standards, and they can be customized to fit your exact needs. Are you ready to improve your procurement strategy with piping options that are always high-quality? If you want to talk about your project needs and how our knowledge can help your business, email us at info@sxqinsteel.com.

References

American Society of Mechanical Engineers. ASME SA-335 Standard Specification for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service. New York: ASME Press, 2023.

Boyer, Howard E. Atlas of Creep and Stress-Rupture Curves for High-Temperature Alloys. Materials Park: ASM International, 2019.

Davis, Joseph R. Heat-Resistant Materials: Properties and Applications in Power Generation and Petrochemical Industries. Cleveland: ASM International, 2022.

Metals Handbook Committee. Properties and Selection of Ferritic Alloy Steels for High-Temperature Applications. 10th Edition, Volume 1. Materials Park: ASM International, 2021.

Viswanathan, R. Damage Mechanisms and Life Assessment of High-Temperature Components in Power Plants. Materials Park: ASM International, 2020.

Wright, Ian G. High-Temperature Corrosion and Materials Applications in Power Generation Systems. Materials Park: ASM International, 2018.