- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

ASTM A105 Steel Flanges

Xi 'An QinSteel Trading Co., Ltd – Professional ASTM A105 Steel Flanges Manufacturer & Global Supplier

ASTM A105 Steel Flanges are the backbone of high-pressure piping systems, engineered to withstand extreme temperatures and demanding industrial environments. At Xi 'An QinSteel, we specialize in manufacturing carbon steel flanges that meet rigorous ASME, API, and EN standards, ensuring reliability for oil & gas, petrochemical, and power generation projects worldwide.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN 15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Material & Manufacturing Excellence

- Material: ASTM A105 carbon steel, heat-treated for enhanced tensile strength (up to 70 ksi) and impact resistance.

- Certifications: Compliant with ASME B16.5, API 6A, PED 2014/68/EU, and ISO 9001.

- Surface Options: RF, FF, RTJ finishes; anti-corrosion coatings (galvanized, XT-coating).

Why ASTM A105 Steel Flanges Stand Out?

✅ Unmatched Durability

Designed for sour service (H2S environments) and cryogenic conditions, our flanges undergo Charpy impact testing and ultrasonic inspection to prevent leaks under stress.

✅ Global Compliance

Pre-certified for GCC (Qatar CQC), EU (PED), and ASEAN markets, reducing approval delays for your projects.

✅ Rapid Customization

Need non-standard bore sizes or Spectacle Blind Flanges? Our OEM/ODM services deliver tailored solutions in 10–15 days.

Applications

- Oil & Gas: Offshore platforms, refinery pipelines.

- Power Plants: High-temperature steam lines, nuclear cooling systems.

- Water Infrastructure: Pump stations, treatment plants.

Why Choose Xi 'An QinSteel?

🔧 15K+ Ready-to-Ship Flanges

From Class 150 slip-ons to Class 2500 weld necks, our ASTM A105 Steel Flanges stock ensures 24/7 delivery for urgent orders.

🔧 Precision Without Compromise

Advanced CNC machining guarantees ±0.01mm dimensional accuracy, ensuring leak-proof performance.

🔧 Full Traceability

Every batch includes MTCs (Material Test Certificates) with heat numbers and chemical analysis.

Quality Assurance

- Testing: Hardness (Rockwell B), hydrostatic pressure, and PMI (Positive Material Identification).

- NDE: Liquid penetrant and radiographic testing for defect-free flanges.

Shipping & Packaging

- Secure Transit: Export-grade crates with moisture-resistant coating and edge protectors.

- Global Reach: FOB/CIF shipments to Middle East, Europe, Americas, and Asia-Pacific.

Quality Control

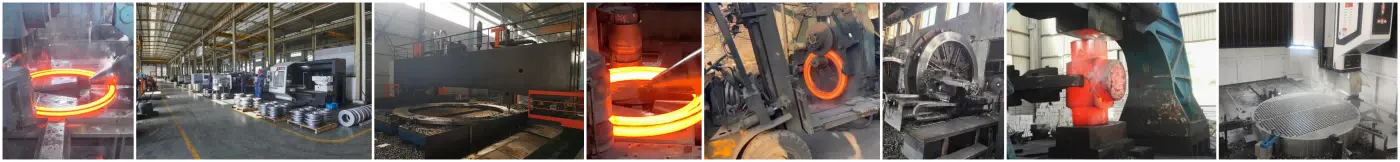

Factory Equipment

Shipping Packaging

FAQs

Q: Are your ASTM A105 flanges suitable for sour gas applications?

A: Yes! We offer NACE MR-0175 compliant options with normalized heat treatment for H2S resistance.

Q: Can I order small quantities for a prototype pipeline?

A: Absolutely. We support low MOQ orders and provide free samples for quality verification.

Q: How do you ensure flange durability in coastal environments?

A: Our XT-coating technology adds 3x corrosion protection vs. standard galvanizing.

Q: What’s the lead time for 500 Class 300 weld neck flanges?

A: In-stock items ship within 48 hours. Custom orders take 7–10 days.

Contact Us

Email: info@sxqinsteel.com

Let's Build Your ASTM A105 Steel Flanges Pipeline's Foundation – Stronger, Safer, Sooner.

Learn about our latest products and discounts through SMS or email