ASME B16.5 slip-on flanges pressure ratings are very important for procurement professionals who work in today's difficult manufacturing environment. In the oil and gas, power generation, and chemical processing businesses, these standard parts are used to connect pipes to each other. Choosing the right pressure rating affects the safety, efficiency, and reliability of the system in the short and long run. The pressure classes from Class 150 to Class 2500 each have a temperature-pressure relationship that helps find the safe working limits. When buying teams choose slip-on flanges for their projects, this all-inclusive guide goes over the technical details, pros and cons of different options, and real-world issues that they need to think about.

Understanding Pressure Ratings in ASME B16.5 Slip-On Flanges

Pressure ratings are important signs that help people choose slip-on flanges for piping uses. The choice affects both safety and the system's ability to work. These numbers show the most pressure a flange can handle at certain temperature ranges. This makes sure that it will always work properly. Standard pressure levels, from 150 to 2500, make clear which flange dimensions and material strengths are appropriate.

Temperature-Pressure Relationships

Flange grades are based on temperature and pressure working together in ways that are known to engineers. As the temperature rises, the pressure that can be safely used drops because materials lose strength when they get hotter. Class 150 flanges are usually used when pressure is low. They can handle 285 PSI at room temperature, but only 180 PSI at 400°F. In higher pressure classes, this opposite link becomes more clear. For example, Class 2500 flanges hold 6170 PSI at room temperature, but at 400°F, that number drops to 3705 PSI.

Material Grade Impact on Pressure Capacity

Key factors that have a big impact on the pressure number that can be reached are the grade of the material, the temperature at which it operates, and the thickness of the flange. Carbon steel grades such as A105 provide excellent strength for standard applications, while stainless steel variants like A182 F316 offer better corrosion protection in harsh environments. Duplex stainless steels, such as F51, F53, and F55, are stronger and better at resisting corrosion than other steels. This makes them a good choice for offshore and sour gas uses where standard materials might fail.

ASME B16.5 Slip-On Flange Design and Pressure Rating Standards

The ASME B16.5 standard carefully lays out the pressure classes, materials, measurements, and tolerances needed for slip-on flanges so that they can be safely used in a variety of industries. This makes things work together no matter where they are in the world, and it makes buying things easier for projects that work in multiple countries.

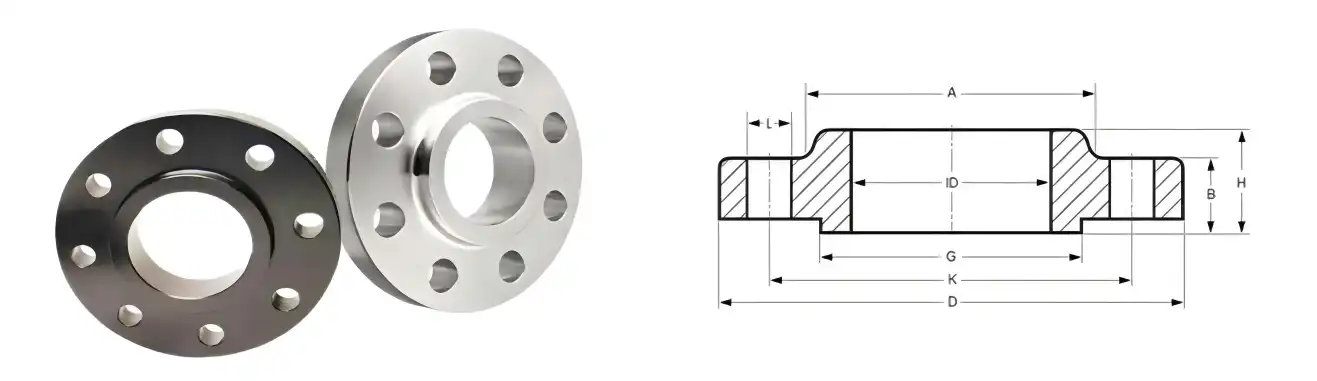

Dimensional Standards and Thickness Requirements

Flange thickness and adherence to dimensional standards are very important in getting the desired pressure ratings. Flanges that are thicker usually work with higher pressure classes because the wider material and better load spread make them stronger. For precise production, the standard sets exact measurements for hub thickness, ASME B16.5 SO flange diameter, and bolt circle diameter, and tolerances are kept within ±0.1mm. These physical controls make sure that the gasket is properly compressed and that the stress is evenly spread when pressure is applied.

Material Specifications and Strength Properties

Because of their different strength and ability to fight rust, materials like carbon steel, stainless steel, and alloy steel each affect the ability of a structure to withstand pressure in their own way. Carbon steel A105 has a minimum tensile strength of 70,000 PSI, but stainless steel A182 F304 has 75,000 PSI and is also more resistant to rust. A182 F11 chromium-molybdenum steel is a specialty alloy that works better at high temperatures because it keeps its power when the temperature rises, unlike carbon steel which would weaken.

Comparing Pressure Ratings: Slip-On Flanges vs. Other Types

Because of how they are built, slip-on flanges usually have lower pressure values than weld neck flanges. This affects how well each type works in different pressure situations. This review shows buyers the pros and cons of different flange types so they can choose the best one for their needs.

Structural Design Differences

Weld neck flanges are made with a hub, which makes them stronger for systems with high pressure and high temperature. Slip-on flanges are easier to install and cheaper for systems with mild pressure. The slip-on design has a concentrated stress at the base of the hub because of how it's made, which limits the amount of pressure it can handle compared to the gradual shift in weld neck designs. But this drawback is canceled out by needing less welding and having shorter construction times.

Facing Types and Sealing Performance

Slip-on flanges often provide balanced performance for pressure handling with more flexibility compared to lap joint and threaded flanges. Flanges can have raised face (RF), flat face (FF), or ring-type joint (RTJ) facings. These are very important to how well the flange can seal and how much pressure it can take. RTJ facings give the best pressure ratings by sealing metal to metal. RF facings work well with standard gaskets in most industrial settings.

Practical Considerations for Buyers: Selecting Slip-On Flanges by Pressure Ratings

When procurement experts choose slip-on flanges, they have to think about a lot of things, including the pressure ratings. It is very important to make sure that flange pressure values are in line with the way the system actually works. This avoids over- or under-specification, which can affect both the safety and the cost of a project.

System Operating Conditions Analysis

The right flange class is based on knowing the link between pressure and temperature in your case. Systems that work at 600 PSI and 300°F need to be thought about differently than ones that work at 150 PSI and room temperature. It is common for safety factors to be between 1.5 and 4.0. The exact number depends on how important the application is and on the rules of the business. Because of the possible effects of failure, chemical processing plants usually need higher safety factors. On the other hand, water treatment plants may be able to get by with normal safety gaps.

Cost-Effectiveness and Budget Optimization

Cost-effectiveness is an important thing to keep in mind when looking at price differences caused by material selection and pressure class. It costs more to make the tighter specs and more material that higher pressure classes need. It's common for Class 150 flanges to be 30% to 40% cheaper than similar Class 300 ones. On the other hand, Class 2500 flanges can be 300% to 400% more expensive than Class 150 ones. Material selection also affects the price. For example, stainless steel flanges are 200% to 300% more expensive than carbon steel ones, and flanges made of specialty metals are even more expensive.

Supplier Evaluation Criteria

To make sure that ASME B16.5 slip on flanges are reliable and meet the standards, buyers should focus on providers with known certifications and strict quality control. ISO 9001, API 6A, ASME B16.5, and NACE MR0175 for sour service are important certifications. NACE MR0175 is an example of an approval that is special to the industry. While keeping these certificates, QinSteel offers full material traceability and a three-step inspection process that includes checking the materials, ensuring machining accuracy, and performing pressure testing at 200% of the rated pressure.

How to Verify and Ensure Proper Installation Based on Pressure Ratings?

It is still very important to keep the accuracy of the pressure numbers during installation in order to keep the system safe and working. If you put it correctly, the engineered pressure capacity will stay intact and it will work in tough industrial settings for a long time.

Installation Best Practices

Using the right amount of power and the right gasket helps keep pressure loads from leaking or breaking flanges. ASME PCC-1 guidelines must be followed when determining bolt torque. These guidelines set out torque patterns and values depending on flange size, pressure class, and bolt material. Evenly adding the bolts keeps the gasket from extruding and makes sure the seal stays in place even when the pressure changes. In systems where the temperature changes a lot, thermal expansion and temperature cycling must be kept in mind.

Maintenance and Inspection Protocols

After installation, regular checks that focus on flange changes, obvious wear, or gasket breakdown help the service last longer and find possible risks early on. It depends on how the equipment is used when inspections are needed, but areas with high pressure or chemicals that can eat away at materials need more frequent checks. Gasket extrusion, bolt corrosion, and flange face damage should be looked at during a visual inspection. Leak detection under operating pressure supports sealing integrity.

QinSteel's ASME B16.5 Slip-On Flange Solutions

QinSteel's main business is making and delivering precision-engineered slip-on flanges designed for customers in the industry around the globe. We offer a wide range of certified flanges made of different materials, such as A105 carbon steel, A350 LF2 low-temperature carbon steel, and high-quality stainless steel grades A182 F304, F316, and F51, F53, and F55. Our flanges meet all standard pressure classes from Class 150 to Class 2500.

Product Range and Capabilities

We offer slip-on flanges in sizes from ½" to 24" with a variety of facing choices, such as RF, FF, RTJ, M&F, and T&G. Each flange is tested for quality, which keeps the dimensional tolerances within ±0.1mm and the pressure tests at 200% of the rated capacity. For non-standard uses, we offer OEM/ODM customization and sampling services to help customers make up their minds.

Quality Assurance and Certifications

We help global sourcing projects with technical knowledge and quick service because we are committed to strict quality control, customization, and on-time delivery. Our factory is ISO 9001 certified, ASME B16.5 compliant, and has API 6A approval. With every shipment, material traceability paperwork is sent to make sure that all of the contents meet both global standards and customer requirements.

Conclusion

Understanding pressure values in ASME B16.5 slip-on flanges gives procurement teams the power to make smart choices that find a balance between safety, performance, and cost. The best flange specifications for each project are based on the link between the pressure class, temperature limits, choice of material, and the needs of the application. If you install and take care of things correctly, they will keep their designed pressure ratings for the whole time they are in service. Projects will be successful and long-term operating reliability will be ensured if certified suppliers are used who offer technical support, quality documentation, and customization options.

FAQs

How much pressure can a normal ASME B16.5 slip-on flange handle?

ASME B16.5 slip-on flanges can handle up to 6170 PSI at room temperature, with a pressure value of Class 2500. This, though, is a lower limit at higher temperatures; it drops to about 3705 PSI at 400°F. The real maximum pressure relies on the material grade, the temperature at which it works, and the safety factors your application needs.

How do slip-on flanges' pressure ratings change when the temperature changes?

Due to weaker material strength at higher temperatures, pressure rates are greatly affected by changes in temperature. According to known temperature-pressure graphs, the pressure that is safe drops as the temperature rises. At 400°F, class 150 flanges can only take 180 PSI, even though they are designed for 285 PSI at room temperature. At higher temperatures and pressure classes, this inverse link is easier to see. This makes it very important to think about temperature when operating safely.

In high-pressure situations, can I use a slip-on flange instead of other kinds of flanges?

Slip-on flanges work well for uses with moderate pressure, but they aren't as good as weld neck flanges in systems with high pressure. Slip-on flanges are easy to install and save money, but their design causes stress concentrations that lower the amount of pressure they can handle. Weld neck flanges usually have better pressure ratings and structural integrity for uses over Class 600 or with very important high-pressure service.

Partner with QinSteel for Premium ASME B16.5 Slip-On Flange Solutions

QinSteel offers slip-on flanges that are precisely made to meet your exact needs for pressure rating with quality and dependability that never wavers. We are a trusted ASME B16.5 slip-on flange manufacturer with over 20 years of experience in the field. We offer a full range of options from standard setups to custom specs. Our global supply system makes sure that projects in the Americas, Africa, Europe, and Southeast Asia get their deliveries on time. For technical help, tailored quotes, and the cost of large orders, email info@sxqinsteel.com.

References

American Society of Mechanical Engineers. "ASME B16.5-2020: Pipe Flanges and Flanged Fittings NPS 1/2 Through NPS 24 Metric/Inch Standard." ASME International, 2020.

Bickford, John H. "Gaskets and Gasketed Joints: Second Edition." Marcel Dekker, Inc., 1998.

Brown, W.F. and Srawley, J.E. "Fracture Toughness Testing Methods for Pressure Vessel Steels." Journal of Engineering for Industry, ASME Transactions, 1966.

Harvey, John F. "Theory and Design of Pressure Vessels: Fourth Edition." Van Nostrand Reinhold, 1991.

Jawad, Maan H. and Farr, James R. "Structural Analysis and Design of Process Equipment: Third Edition." John Wiley & Sons, 2006.

Megyesy, Eugene F. "Pressure Vessel Handbook: Fourteenth Edition." Pressure Vessel Publishing, Inc., 2008.