Understanding Socket Weld Flanges and Their Importance

What are Socket Weld Flanges?

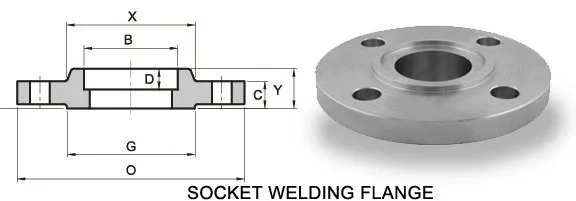

Socket weld flanges are specialized pipe fittings designed to create strong, permanent connections between pipes and other components in a piping system. These flanges feature a socket or recessed area into which the pipe is inserted and welded, creating a seamless and robust joint. Socket weld flanges are widely used in high-pressure and high-temperature applications due to their excellent sealing capabilities and resistance to leaks.

Benefits of Socket Weld Flanges

Socket weld flanges offer several advantages over other flange types, making them a popular choice in various industries. Some key benefits include:

- Enhanced leak resistance

- Improved structural integrity

- Reduced turbulence in fluid flow

- Compatibility with small-diameter pipes

- Suitability for high-pressure and high-temperature applications

These advantages make socket weld flanges ideal for use in critical systems where reliability and safety are paramount.

Applications of Socket Weld Flanges

Socket weld flanges find extensive use across various industries and applications, including:

- Oil and gas pipelines

- Chemical processing plants

- Power generation facilities

- Petrochemical refineries

- HVAC systems

- Water treatment plants

The versatility and reliability of socket weld flanges make them indispensable in these critical sectors, where maintaining system integrity is essential.

Factors to Consider When Matching Socket Weld Flange Size with Pipes

Pipe Outer Diameter (OD)

The most critical factor in matching socket weld flange size with pipes is the pipe's outer diameter (OD). The flange socket must be sized to accommodate the pipe OD precisely, allowing for a snug fit that facilitates proper welding. To ensure accuracy:

- Measure the pipe OD using a caliper or micrometer

- Consult pipe schedules and standards to verify nominal pipe sizes

- Consider any coatings or insulation that may affect the overall diameter

Accurate measurement of the pipe OD is crucial for selecting the appropriate socket weld flange size.

Flange Pressure Rating

The pressure rating of the socket weld flange must be compatible with the operating pressure of the piping system. Factors to consider include:

- Maximum allowable working pressure (MAWP) of the system

- Temperature fluctuations that may affect pressure ratings

- Safety factors and industry-specific requirements

Selecting a flange with the appropriate pressure rating ensures the integrity and safety of the entire piping system.

Material Compatibility

The materials of the socket weld flange and the pipe must be compatible to ensure a strong, corrosion-resistant connection. Consider the following:

- Chemical compatibility between flange and pipe materials

- Thermal expansion properties of both components

- Resistance to corrosion and erosion in the operating environment

Proper material selection is essential for creating a durable and long-lasting connection that can withstand the demands of the application.

Step-by-Step Guide to Matching Socket Weld Flange Size with Pipes

Measure the Pipe Outer Diameter

To accurately match the socket weld flange size with the pipe, follow these steps:

- Clean the pipe surface to remove any dirt, rust, or coatings

- Use a precision measuring tool like a caliper or micrometer

- Take multiple measurements around the pipe circumference

- Calculate the average OD to account for any slight variations

- Record the measurement in the appropriate units (inches or millimeters)

Accurate measurement is crucial for selecting the correct flange size and ensuring a proper fit.

Select the Appropriate Flange Size

Once you have the pipe OD measurement, follow these steps to select the right socket weld flange:

- Consult flange size charts or specifications from reputable manufacturers

- Match the measured pipe OD to the corresponding flange size

- Verify that the selected flange meets the required pressure rating

- Check the flange material compatibility with the pipe

- Consider any industry-specific standards or regulations

Selecting the correct flange size ensures a proper fit and optimal performance of the piping system.

Verify Fit and Compatibility

Before proceeding with installation, it's essential to verify the fit and compatibility of the socket weld flange with the pipe:

- Perform a dry fit by inserting the pipe into the flange socket

- Ensure the pipe sits flush against the socket bottom

- Check for any gaps or misalignments between the pipe and socket

- Verify that the flange face is perpendicular to the pipe axis

- Confirm that the flange rating and material meet project specifications

Proper verification helps prevent issues during installation and ensures the long-term reliability of the connection.

Conclusion

Matching the size of socket weld flanges with pipes is a critical process that requires attention to detail and adherence to industry standards. By carefully measuring the pipe outer diameter, selecting the appropriate flange size, and verifying compatibility, you can ensure a secure and leak-proof connection in your piping system. Remember to consider factors such as pressure ratings, material compatibility, and specific application requirements when making your selection. With the right approach, you can create robust and reliable piping connections that stand the test of time across various industries and applications.

FAQs

What is the main advantage of using socket weld flanges?

Socket weld flanges offer enhanced leak resistance and improved structural integrity, making them ideal for high-pressure and high-temperature applications.

How do I ensure proper sizing when matching socket weld flanges with pipes?

Accurate measurement of the pipe's outer diameter is crucial. Use precision tools like calipers or micrometers, and consult flange size charts from reputable manufacturers.

Are socket weld flanges suitable for all piping materials?

While socket weld flanges are versatile, it's essential to ensure material compatibility between the flange and pipe. Consult with experts or manufacturers for specific material recommendations.

Expert Socket Weld Flange Solutions | QinSteel

At QinSteel, we specialize in providing high-quality socket weld flanges and expert guidance for all your piping needs. As a leading manufacturer and supplier, we offer a wide range of socket weld flange solutions engineered to meet the most demanding industry standards. Our team of experienced professionals is ready to assist you in selecting the perfect flange for your application. Contact us at info@sxqinsteel.com to discuss your socket weld flange requirements and experience our commitment to excellence.

References

Smith, J. (2022). "Handbook of Piping System Design and Installation." Industrial Press.

Johnson, R. (2021). "Socket Weld Flange Selection Guide." Piping Engineering Journal, 15(3), 45-52.

American Society of Mechanical Engineers. (2023). "ASME B16.5: Pipe Flanges and Flanged Fittings."

Brown, T. (2020). "Best Practices for Socket Weld Flange Installation." Pipeline Technology Conference Proceedings.

International Organization for Standardization. (2022). "ISO 7005: Metallic flanges - Part 1: Steel flanges."

Wilson, E. (2021). "Materials Selection for Piping Systems in Corrosive Environments." Corrosion Engineering Journal, 28(2), 112-125.