- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

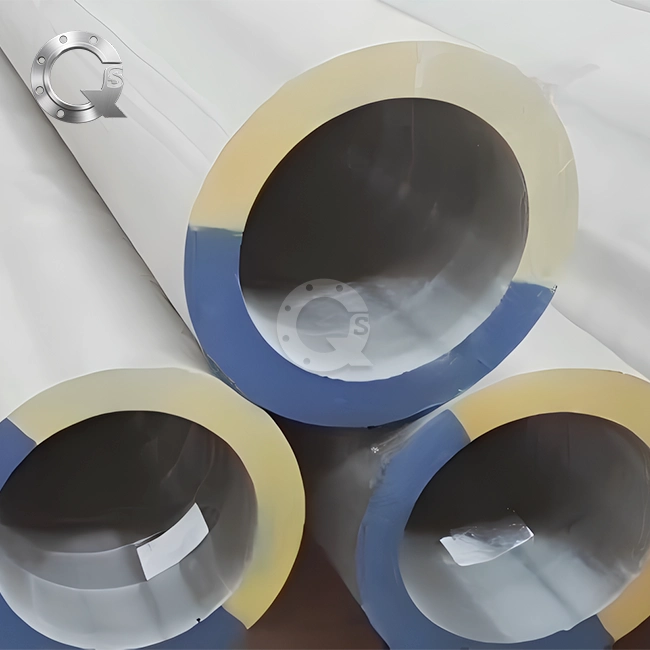

Socket Weld Pipe Flanges

Xi 'An QinSteel Trading Co., Ltd | Premium Socket Weld Pipe Flanges Manufacturer & Global Supplier

When you need reliable, high-pressure pipeline solutions, Socket Weld Pipe Flanges from Xi'an QinSteel deliver unmatched performance. Engineered to ASME B16.5, API 6A, and EN 1092-1 standards, our flanges ensure leak-proof connections in oil and gas systems. With ISO 9001, API 6A, and PED certifications, we combine precision manufacturing with global compliance to keep your projects on track.

Product Description

The products create secure, permanent joints in high-pressure piping systems. Their unique socket design allows easy alignment and welding, minimizing turbulence and maximizing flow efficiency. Ideal for oil and gas pipelines, petrochemical plants, and offshore platforms, these flanges withstand extreme temperatures (from -29°C to 425°C) and pressures up to CLASS 2500.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN 15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Material Excellence

Choose from carbon steel (A105/A350 LF2), stainless steel (F304/F316), or duplex alloys (F51/F53) for Socket Weld Pipe Flanges. All materials come with full traceability and Mill Test Reports (MTRs). Need a custom grade? Our R&D team can develop specialized alloys for corrosive or high-temperature environments.

Why Our Socket Weld Pipe Flanges Stand Out?

✅ Zero-Defect Guarantee: Every flange undergoes hydrostatic testing, dimensional checks, and surface finish inspections.

✅ Global Compliance: Pre-validated for API, ASME, EN, JIS, and GOST standards.

✅ Customization Ready: Modify bore sizes, facing types (RF/RTJ/FF), or coatings (PTFE, galvanized) with MOQs as low as 50 units.

✅ Rapid Delivery: 85% of orders ship within 15 days, with emergency stock available for 72-hour dispatch.

Trusted in Critical Applications

- Oil & Gas Transmission Lines: API 6A-certified flanges for wellheads and manifolds.

- Refinery Systems: High-temperature-resistant A182 F316 flanges.

- Hydraulic Systems: Precision-machined surfaces for vibration resistance.

Why Choose Xi'an QinSteel?

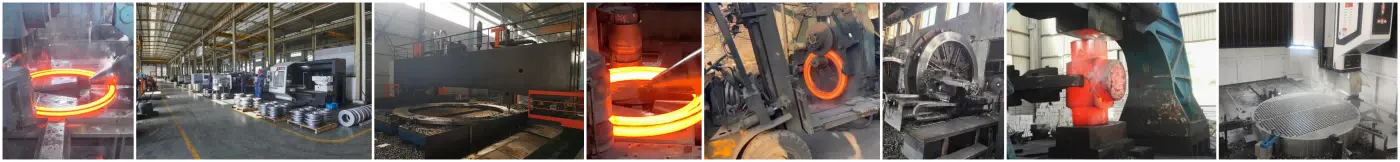

🔧 GMP-Certified Production: Our 15,000㎡ facility uses CNC machining for micron-level accuracy.

🌍 Global Logistics: Regional warehouses in the EU, North America, and Middle East reduce lead times.

📦 Damage-Proof Packaging: Industrial crates with anti-rust VCI films and shock-absorbent padding.

💡 24/7 Engineering Support: From prototype design to installation guidance, we’re your partner.

Quality Assurance Process

1. Material Verification: Cross-check MTRs against ASTM/ASME specs.

2. Dimensional Accuracy: Laser scanning ensures compliance with B16.5 tolerances.

3. Pressure Testing: Hydrostatic tests at 1.5x rated pressure.

4. Surface Inspection: No pitting, cracks, or uneven finishes.

Quality Control

Factory Equipment

Shipping Packaging

FAQs

Q: Can you provide API 6A documentation for audits?

A: Yes! We include test certificates, MTRs, and NDE reports with every shipment.

Q: What's the lead time for 1,000 custom flanges?

A: Custom orders take 25–30 days. In-stock items ship in 7–10 days.

Q: Do your flanges work in sour gas environments?

A: Absolutely. We offer NACE MR0175-compliant options.

Q: How do you prevent transit damage?

A: Flanges are individually wrapped, then secured in wooden crates with edge protectors.

Q: Can I order samples?

A: Yes—request samples via email for quality approval.

Contact Us

Need Reliable Socket Weld Pipe Flanges?

📧 Email: info@sxqinsteel.com

Learn about our latest products and discounts through SMS or email