- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Mild Steel Plain Washers

Trusted Manufacturer & Global Supplier of Mild Steel Plain Washers

At Xi'an QinSteel Trading Co., Ltd, we specialize in high-volume production of Mild Steel Plain Washers engineered for precision and durability. With over [X] years of industrial expertise, our washers meet global standards while offering unmatched customization for machinery assembly needs.

Why Mild Steel Plain Washers Matter in Your Projects?

The products are essential for distributing load, reducing friction, and protecting surfaces in fastening systems. Made from grades like F436, 1035, or 1045 mild steel, they balance strength and affordability for industries ranging from automotive to construction.

Technical Specifications at a Glance

| Parameter | Details |

|---|---|

| Sizes | M5–M100 (Metric), 5/16"–4" (Imperial) |

| Materials | F436, 1035, 1045, 1060, 1070 Steel |

| Standards | ASME B18.21.1, ASTM F436/F844 |

| Coatings | Plain, Zinc, Phosphate, Black Oxide, Hot-Dip Galvanized |

| Hardness | HRB 70–85 (Custom Heat Treatment Available) |

Key Benefits of Choosing Our Washers

1. Precision Fit: CNC-machined to ±0.1mm tolerances for seamless integration with bolts.

2. Corrosion Resistance: Optional zinc or phosphate coatings extend lifespan in harsh environments.

3. Cost Efficiency: Bulk pricing for orders over 50,000 units without compromising quality.

4. Global Compliance: Pre-certified for RoHS (EU), ASTM (NA), and IATF 16949 (automotive).

Where Mild Steel Plain Washers Excel?

- Heavy Machinery: Mild Steel Plain Washers distribute clamping force in agricultural/construction equipment.

- Automotive Assembly: Prevent bolt loosening under vibration in engines/chassis.

- Renewable Energy: Secure fasteners in wind turbine/solar panel installations.

- OEM Projects: Custom sizes/coatings for hydraulic systems or specialized tools.

Why Partner With Us?

🏭 Manufacturing Excellence

- GMP-Certified Facilities: 20+ automated stamping lines ensure batch consistency.

- Agile Customization: Modify inner/outer diameters, thickness, or coatings in 10k+ MOQ batches.

- Traceable Materials: Full ASTM/DIN mill test reports provided.

🌍 Global Reach, Local Speed

- Regional Warehouses: Stocked inventory in EU/NA/Asia for ≤15-day delivery.

- Secure Packaging: Anti-rust VCI films + reinforced cartons prevent transit damage.

🔍 Rigorous Quality Control

- 3-Stage Inspections: Dimensional checks, hardness testing, and coating adhesion audits.

- Certifications: ISO 9001, RoHS, REACH, and OEM-specific compliance.

Quality Control

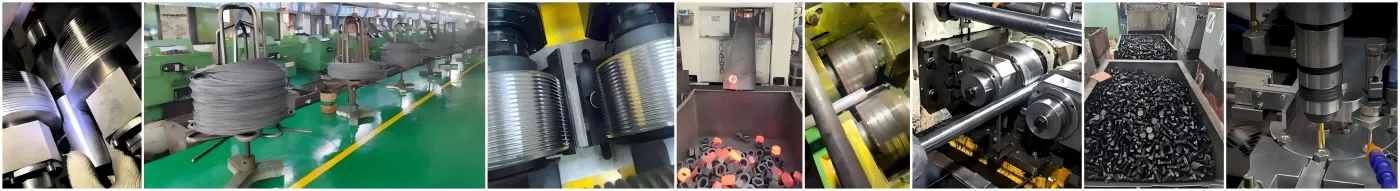

Factory Equipment

Shipping Packaging

FAQs: Your Questions, Answered

Q: Can I get samples before placing a bulk order?

A: Yes! We offer free standard samples. Custom samples ship within 3 working days.

Q: Do you support urgent OEM orders?

A: Absolutely. Our large inventory and JIT channels ensure 10–14-day lead times for 100k+ units.

Q: How do you prevent corrosion in uncoated washers?

A: We use vacuum-sealed packaging with moisture-absorbing desiccants for long-term storage.

Q: Are your products compliant with automotive standards?

A: Yes, we hold IATF 16949 certification and provide PPAP documentation upon request.

Contact Us

Need Mild Steel Plain Washers tailored to your project? Our R&D team is ready to help:

📧 Email: info@sxqinsteel.com

Learn about our latest products and discounts through SMS or email