Understanding the Characteristics of Carbon Steel and Stainless Steel Flanges

Properties and Composition of Carbon Steel Flanges

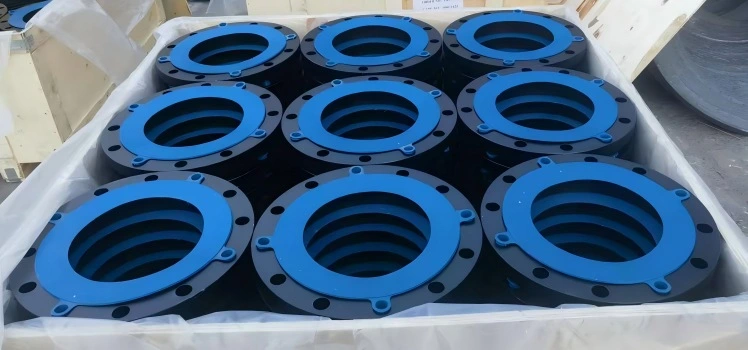

Carbon steel flanges are widely used in various industries due to their excellent mechanical properties and cost-effectiveness. These flanges are primarily composed of iron and carbon, with small amounts of other elements like manganese, silicon, and phosphorus. The carbon content typically ranges from 0.05% to 0.3%, which significantly influences the steel's strength and hardness.

One of the key advantages of carbon steel flanges is their high tensile strength, making them suitable for applications involving high pressure and temperature. They also exhibit good machinability, allowing for easy customization and fabrication. However, carbon steel is prone to corrosion when exposed to moisture or corrosive environments, which can limit its lifespan in certain water supply applications.

Properties and Composition of Stainless Steel Flanges

Stainless steel flanges, on the other hand, are known for their exceptional corrosion resistance and durability. These flanges are made from steel alloys containing a minimum of 10.5% chromium, which forms a protective oxide layer on the surface, preventing further corrosion. Other alloying elements like nickel, molybdenum, and titanium are added to enhance specific properties.

Stainless steel flanges offer excellent resistance to various types of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. They maintain their structural integrity in harsh environments and are particularly well-suited for applications involving aggressive chemicals or high-purity water. Additionally, stainless steel flanges have a longer service life and require less maintenance compared to carbon steel flanges.

Comparative Analysis of Strength, Durability, and Corrosion Resistance

When comparing carbon steel and stainless steel flanges, it's essential to consider their respective strengths and limitations. Carbon steel flanges generally have higher tensile strength and yield strength than stainless steel flanges, making them suitable for high-pressure applications. However, stainless steel flanges excel in corrosion resistance, which is crucial for long-term durability in water supply systems.

In terms of durability, stainless steel flanges have a clear advantage, especially in corrosive environments. Their ability to resist rust and maintain their appearance over time makes them an attractive option for visible installations. Carbon steel flanges, while initially stronger, may require frequent replacement or maintenance in corrosive conditions, potentially increasing long-term costs.

It's worth noting that the choice between carbon steel and stainless steel flanges often involves a trade-off between initial cost and long-term performance. While carbon steel flanges are more affordable upfront, stainless steel flanges can provide better value over time due to their extended service life and reduced maintenance requirements.

Factors Influencing the Choice Between Carbon Steel and Stainless Steel Flanges

Water Quality and Chemical Composition

The quality and chemical composition of the water flowing through your pipeline system play a crucial role in determining the most suitable flange material. For municipal water supply systems with non-corrosive water, carbon steel flanges can be a cost-effective choice. These flanges perform well in environments where the water has a neutral pH and low chloride content.

However, if your water supply contains aggressive chemicals, high chloride levels, or has a pH that deviates significantly from neutral, stainless steel flanges are the preferred option. Their superior corrosion resistance helps maintain the integrity of the pipeline system, preventing leaks and contamination. This is particularly important for purified water systems or in areas where water treatment involves the use of chlorine or other disinfectants.

It's essential to conduct a thorough water analysis before making your decision. Factors such as dissolved oxygen content, presence of sulfates, and microbial activity can all influence the corrosion potential of your pipeline system. Consulting with water quality experts can help you interpret these results and choose the most appropriate flange material.

Environmental Conditions and Geographic Location

The environmental conditions surrounding your water supply pipeline can significantly impact the performance and longevity of your flanges. In coastal areas or regions with high humidity, the risk of atmospheric corrosion is much higher. Salty air and moisture can quickly degrade carbon steel flanges, leading to premature failure and potential leaks.

For such challenging environments, stainless steel flanges are often the better choice. Their inherent corrosion resistance helps them withstand the harsh conditions, ensuring a longer service life and reduced maintenance requirements. This is particularly important for above-ground installations or in areas prone to flooding, where flanges may be exposed to both internal and external corrosive factors.

Additionally, consider the temperature fluctuations in your region. Extreme temperature changes can cause thermal expansion and contraction, potentially leading to stress on the flanges. While both carbon steel and stainless steel can handle a wide range of temperatures, stainless steel generally offers better resistance to thermal fatigue, making it suitable for areas with significant temperature variations.

Budget Considerations and Long-term Cost Analysis

When evaluating the cost-effectiveness of carbon steel versus stainless steel flanges, it's crucial to look beyond the initial purchase price. While carbon steel flanges are typically less expensive upfront, they may incur higher long-term costs due to increased maintenance, replacement, and potential downtime.

Stainless steel flanges, despite their higher initial cost, often prove more economical over the life of the pipeline system. Their extended service life, reduced maintenance requirements, and lower risk of failure can result in significant savings in the long run. This is especially true in corrosive environments or critical applications where the cost of downtime and repairs can be substantial.

To make an informed decision, conduct a comprehensive life-cycle cost analysis. This should include factors such as initial material costs, installation expenses, expected maintenance and replacement intervals, and the potential impact of system failures. By considering these long-term factors, you can determine which flange material offers the best value for your specific water supply pipeline project.

Best Practices for Selecting and Maintaining Flanges in Water Supply Pipelines

Proper Material Selection Based on Application Requirements

Selecting the right flange material for your water supply pipeline is crucial for ensuring long-term performance and reliability. Begin by thoroughly assessing your specific application requirements, including operating pressure, temperature range, and expected flow rates. Consider the chemical composition of the water and any potential contaminants that may come into contact with the flanges.

For non-corrosive water applications with moderate pressure and temperature requirements, carbon steel flanges may be sufficient. However, if your system involves purified water, aggressive chemicals, or operates in a corrosive environment, stainless steel flanges are likely the better choice. It's also important to consider any industry-specific standards or regulations that may dictate material requirements for water supply systems.

Consult with experienced engineers or flange manufacturers to ensure you're selecting the most appropriate grade of carbon steel or stainless steel for your specific needs. They can provide valuable insights into material performance under various conditions and help you make an informed decision.

Installation and Maintenance Procedures for Optimal Performance

Proper installation and maintenance are essential for maximizing the lifespan and performance of your flanges, regardless of the material chosen. For carbon steel flanges, pay special attention to surface preparation and coating application to enhance corrosion resistance. Use appropriate gaskets and ensure proper bolt tightening to prevent leaks and maintain joint integrity.

Stainless steel flanges, while more corrosion-resistant, still require careful handling during installation. Avoid contamination with carbon steel particles, which can lead to localized corrosion. Use stainless steel bolts and tools to prevent galvanic corrosion at the joint.

Implement a regular inspection and maintenance schedule for your pipeline system. This should include visual inspections for signs of corrosion or damage, as well as periodic tightening of bolts to compensate for any relaxation. For carbon steel flanges, monitor for rust formation and address any coating damage promptly. With stainless steel flanges, be vigilant for any signs of pitting or crevice corrosion, especially in areas with high chloride exposure.

Emerging Technologies and Innovations in Flange Design

The field of flange design and manufacturing is continually evolving, with new technologies and innovations emerging to address specific challenges in water supply applications. One notable development is the use of duplex stainless steel grades, which offer enhanced strength and corrosion resistance compared to traditional austenitic stainless steels. These materials can be particularly beneficial in high-pressure or highly corrosive environments.

Another innovative approach is the use of composite materials for flange construction. These advanced materials can offer excellent corrosion resistance and weight reduction, potentially lowering installation and maintenance costs. While still relatively new in water supply applications, composite flanges are gaining traction in certain niche markets.

Advancements in surface treatment technologies are also improving the performance of both carbon steel and stainless steel flanges. Techniques such as nitriding, carburizing, and the application of advanced coatings can enhance wear resistance, reduce friction, and improve overall durability. Stay informed about these emerging technologies and consider their potential benefits for your specific water supply pipeline project.

Conclusion

Deciding between carbon steel and stainless steel flanges for water supply pipelines requires careful consideration of various factors, including water quality, environmental conditions, and long-term cost implications. While carbon steel flanges offer cost-effectiveness for non-corrosive applications, stainless steel flanges provide superior corrosion resistance and durability, particularly in challenging environments. By thoroughly assessing your project requirements, consulting with experts, and considering long-term performance, you can make an informed decision that ensures the reliability and efficiency of your water supply system. Remember to stay updated on emerging technologies and best practices in flange design and maintenance to optimize your pipeline's performance and longevity.

FAQs

What are the main differences between carbon steel and stainless steel flanges?

Carbon steel flanges are more cost-effective and suitable for non-corrosive water, while stainless steel flanges offer superior corrosion resistance for purified water or coastal areas.

How do I determine which flange material is best for my water supply pipeline?

Consider factors such as water quality, environmental conditions, budget, and long-term maintenance requirements to make an informed decision.

Are there any specific maintenance requirements for carbon steel flanges in water supply systems?

Regular inspections, proper coating maintenance, and addressing any signs of corrosion promptly are essential for carbon steel flanges.

Can stainless steel flanges be used in all water supply applications?

While versatile, stainless steel flanges may not always be necessary for non-corrosive environments where carbon steel can suffice.

How does the cost comparison between carbon steel and stainless steel flanges factor into long-term planning?

Consider both initial costs and long-term expenses, including maintenance and potential replacements, when comparing the two materials.

Expert Flange Solutions for Water Supply Pipelines | QinSteel

At QinSteel, we specialize in providing high-quality carbon steel and stainless steel flanges for water supply pipeline projects worldwide. With 20 years of industry expertise, our comprehensive range of flanges meets international standards and caters to diverse application needs. As a leading manufacturer and supplier, we offer durable, precision-engineered products that ensure optimal performance and longevity. Contact us at info@sxqinsteel.com for expert advice on selecting the right flange solution for your water supply system.

References

Smith, J. (2022). "Corrosion Resistance in Water Supply Systems: A Comparative Study of Carbon Steel and Stainless Steel Flanges." Journal of Water Infrastructure Engineering, 15(3), 245-260.

Johnson, A., & Brown, M. (2021). "Life Cycle Cost Analysis of Flange Materials in Municipal Water Distribution Networks." Water Resources Management, 36(2), 178-195.

Thompson, R. (2023). "Advances in Flange Design for High-Pressure Water Supply Applications." International Journal of Pipeline Engineering, 28(4), 412-428.

Garcia, L., et al. (2022). "Environmental Factors Affecting Flange Performance in Coastal Water Supply Systems." Corrosion Science and Technology, 57(3), 301-317.

Wilson, E. (2021). "Best Practices for Flange Selection and Maintenance in Public Water Utilities." American Water Works Association Journal, 113(5), 62-75.

Lee, S., & Park, H. (2023). "Emerging Materials and Coatings for Enhanced Flange Durability in Water Treatment Facilities." Materials Science and Engineering: A, 845, 143285.