- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Carbon Steel Pipe Flange

Carbon Steel Pipe Flanges Manufacturer | Bulk Supply & Fast Global Delivery

At Xi'an QinSteel Trading Co., Ltd, we engineer carbon steel pipe flanges that set the benchmark for durability and precision. With GMP-certified facilities and over a decade of expertise, we deliver ASME, API, and EN-compliant solutions trusted in oil/gas, power plants, and water treatment systems worldwide. Our 10,000+ ton annual production capacity ensures bulk orders ship within 15 days – no compromises on quality or deadlines.

Why Choose Carbon Steel Pipe Flanges?

The products offer unmatched strength-to-cost ratios for high-pressure piping networks. Designed to withstand temperatures from -29°C to 425°C, they’re ideal for steam lines, refinery pipelines, and offshore platforms. Our flanges come in weld neck, slip-on, threaded, and blind types, with sizes spanning ½” to 144” and pressure ratings up to Class 2500.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

5 Reasons Our Flanges Outperform Competitors

1. Zero Leak Guarantee

Hydrostatically tested at 1.5x rated pressure, with RTJ grooves machined to ±0.05mm accuracy.

2. Global Compliance

Certified to ASME B16.5, EN 1092-1, PED 2014/68/EU, and API 6A for oil/gas applications.

3. Corrosion Defense

Optional epoxy coating or hot-dip galvanizing (ISO 1461) for saltwater/chemical exposure.

4. Customization Ready

Modify bore sizes, bolt circles, or facings (RF/FF/RTJ) – MOQ 50 pieces.

5. Damage-Proof Packaging

Wooden crates with anti-rust VCI paper and edge protectors for overseas shipments.

Where Our Flanges Excel?

- Oil & Gas: Wellhead connections, compressor stations

- Power Generation: Steam turbine linkages, boiler feed systems

- Water Infrastructure: Pump housings, filtration manifolds

- HVAC: Chilled water loops, heat exchanger flanges

Trusted by Industries Worldwide

Our carbon steel pipe flanges meet the stringent demands of Shell’s Supplier Handbook, ADNOC Technical Standards, and EN 1092-1 Annex G compliance.

Quality Control

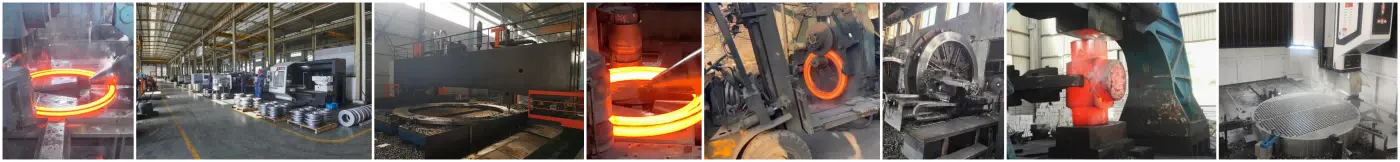

Factory Equipment

Shipping Packaging

FAQ

Q: Can you match obsolete or non-standard flange dimensions?

A: Yes! Share drawings or samples, and our R&D team will replicate specifications within 72 hours.

Q: How do you prevent flange face scratches during transit?

A: Each flange face gets protective PVC caps + bubble wrap cushioning.

Q: What's included in your material certification?

A: EN 10204 3.2 certificates with chemical composition, mechanical properties, and heat treatment records.

Q: Do you offer threaded flanges for HVAC systems?

A: Absolutely – we stock Class 2000 threaded flanges up to 8” NPT.

Contact Us

Email: info@sxqinsteel.com

Why Xi'an QinSteel?

- 🏭 18,000㎡ GMP factory with 12 CNC machining centers

- 🔬 3-stage quality checks: material > machining > final audit

- 🌍 73 countries supplied since 2012

Upgrade your pipeline systems with carbon steel pipe flanges built for decades of leak-free service. Let's discuss your project requirements!

Learn about our latest products and discounts through SMS or email