The A106 B pipe is a very important part of modern industrial plumbing systems. It works very well in situations with high heat and high pressure. Petroleum, chemical, and power generation businesses rely on this seamless carbon steel pipe, made to ASTM A106 Grade B standards for excellent performance and dependability. These pipes have become the most popular choice for very important building projects around the world. They are the strongest option, with a tensile strength over 415 MPa, and they keep working even when temperatures reach 425°C. Engineers and buying experts can make smart choices for their most difficult uses when they know all the benefits of A106 Grade B seamless pipes.

Overview of A106 Grade B Pipe

A106 Grade B pipes are the most important part of industrial piping systems. They follow the ASTM A106 standards for seamless carbon steel pipes designed for high-temperature service uses. These standards cover important dimensions from 1/8" to 80" (10.3 mm to 2032 mm), with thicknesses from Schedule 5 to XXS, which makes sure that a wide range of project needs are met.

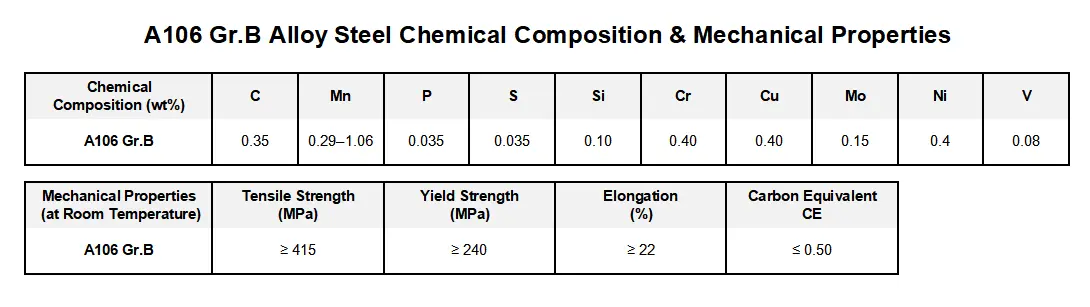

Chemical Composition and Mechanical Properties

The chemicals in ASTM A106 Grade B seamless pipes are required to follow strict industry standards. The carbon level can't go over 0.30%, and manganese must be between 0.29% and 1.06%. This exact mixture has a minimum tensile strength of 415 MPa and a yield strength of 240 MPa. These qualities have a direct effect on how well the pipe works in difficult industrial settings where the integrity of the structure cannot be weakened.

Manufacturing Process and Quality Assurance

Making seamless pipe gets rid of welded joints, which makes the wall thickness and mechanical features of the whole pipe structure the same. Methods of heat treatment used in production improve the grain structure and material properties. To meet strict operational needs in the oil and gas, power generation, and petrochemical industries, quality assurance methods use hydrostatic testing, ultrasonic inspection, and radiographic examination.

Technical Characteristics and Performance Advantages

A106 B seamless pipes have outstanding technical features that make them the best choice for industries where performance and dependability are a must. Engineers can choose the best piping option for their needs when they understand these factors.

Pressure and Temperature Resistance

These pipes are great at handling high-pressure systems. They can handle loads of up to 3,000 PSI without breaking. They can handle temperatures from −29°C to 425°C, so they are great for use in factories and power plants where thermal cycling happens all the time. This range of temperatures is higher than those of many other materials, which gives engineers faith in the long-term performance of the system.

Corrosion Resistance and Durability

Carbon steel does not fight corrosion as well as stainless steel, but A106 Grade B pipes work fine for many industrial settings. When needed, protective coatings and cathodic protection systems can make things more resistant to rust. The seamless construction gets rid of possible weak spots that are common in welded options. This makes the product more durable and lowers the need for upkeep.

Installation and Fabrication Advantages

Best methods for welding, bending, and installing keep the mechanical properties that make these pipes useful. Because the material is easy to machine, you can do very exact beveling, cutting, and threading. Different installation needs and ways to make a link are met by a range of end shapes, such as plain, beveled, threaded, and grooved.

Applications and Industry Uses

A106 Grade B seamless pipes are very important in many heavy businesses because they can handle very high and low temperatures and high pressure. These uses show how useful and dependable these pipes are, which is why they have become the standard in the business.

Oil and Gas Sector Applications

Transmission pipelines, processing equipment, and delivery systems all depend on A106 B seamless pipes for upstream, midstream, and downstream activities. Refineries use these pipes in distillation columns, heat exchanges, and steam systems where they need to work at high temperatures. The pipes are API standard compliant, which makes sure they can be used with fuel infrastructure that is already in place.

Power Generation and Energy Projects

Thermal power plants use these seamless pipes in their boiler systems, steam lines, and cooling loops, where temperature changes and high pressures are normal. Nuclear plants use A106 Grade B pipes in secondary cooling systems and other equipment where long-term dependability and traceability of the materials are very important. More and more, renewable energy projects need these lines for geothermal and concentrated solar power uses.

Chemical and Process Industries

A106 Grade B seamless pipes have precise dimensional limits and good chemical compatibility. Chemical plants, fertilizer makers, and specialty chemical manufacturers rely on them. The even wall thickness and steady mechanical qualities that seamless building offers are good for process piping systems. Because the material stays stable when it's heated and cooled, it can be used in batch processing processes.

Procurement and Supply Chain Considerations

To get A106 Grade B seamless pipes, you need to know how to find the best suppliers and judge them fairly. Strategic procurement choices affect the length of time and prices for projects, as well as the long-term success of operations.

Supplier Certification and Quality Standards

ISO 9001, ASME, and other applicable foreign standards must be followed by certified manufacturers. The evaluation of production capabilities includes looking at the methods for quality control, the manufacturing capacity, and the testing facilities. Mill test certificates, documents that show where the material came from, and accounts of inspections by people not involved with the company all prove that a product is compliant.

Cost Optimization and Inventory Management

Pricing trends show the cost of materials, how much production capacity is being used, and demand patterns around the world. Buying in bulk can save a lot of money and make sure that there is always enough stuff on hand to keep projects going. Finding the right balance between the costs of having inventory and the risks of running out of stock is part of supply chain optimization, especially for applications on the critical path.

Logistics and Global Supply Chain

The time it takes to ship a package depends on the availability of the product, the time it takes to make it, and the means of transportation. International procurement plans are impacted by customs rules and paperwork that need to be filled out. Regional warehouse plans can help get things to people faster and give them extra stock for when they need it right away.

QinSteel: Your Trusted A106 Grade B Pipe Partner

Xi'An QinSteel Trading Co., Ltd has been in the world industrial piping business for twenty years and specializes in ASTM A106 Grade B seamless pipes that can be used in the most difficult situations. Our promise to quality and customer happiness has led to long-term relationships across the Americas, Africa, Europe, and Southeast Asia.

Comprehensive Product Range and Customization

Our large stock includes all common thicknesses from 5 to 80 inches and lengths from 1/8 inch to 80 inches, so we can meet your needs right away. Custom fabrication can make parts with non-standard sizes, special coatings, or custom marking needs. OEM/ODM services change our goods so that they can be used for certain technical specifications and project needs.

Our A106 B pipes have the following benefits:

- Material Excellence: This is high-quality carbon steel that complies with ASTM A106 and has the same mechanical qualities in every batch. The carbon level is 0.30% or less, and the manganese level is between 0.29% and 1.06%.

- Quality Control: Before shipping, these products are tested using hydrostatic, ultrasonic, and radiographic inspection to make sure they are intact and can work well.

- Global Compliance: ISO 9001, PED (EU), and CSA (Canada) certifications make sure that foreign projects are accepted and follow the rules everywhere.

- Excellence in the Supply Chain: With more than 10,000 metric tons of raw materials on hand in regional warehouses in the UAE, the US, and Germany, shipping times of 7 to 14 days are possible.

When procurement professionals are looking for important piping parts, these benefits make it easier to plan output and make sure that the right quality is met.

Value-Added Services and Support

Technical advice services help people choose the right materials and create specifications for certain uses. Third-party verification and help with paperwork are part of inspection support that can speed up the project approval process. Custom transportation plans take into account each project's unique delivery needs and installation timelines.

Conclusion

A106 Grade B seamless pipes have great performance qualities that make them necessary for industrial applications with high temperatures and pressures. They are the best choice for important piping systems because they have better mechanical properties, are made according to reliable manufacturing standards, and have been used successfully in many different industries. Engineers are sure that the system will work for a long time because of the pressure strength up to 3,000 PSI, the temperature capability up to 425°C, and the fact that it is made without seams. Strategic procurement partnerships with certified sellers make sure you get good products at reasonable prices and get full support that helps your projects succeed.

FAQs

What is the difference between smooth Grade A and Grade B A106 pipes?

A106 Grade B pipes have better mechanical qualities than Grade A pipes because they have higher yield strength (at least 240 MPa versus 205 MPa) and tensile strength (at least 415 MPa versus 330 MPa). Grade B is also better at resisting changes in temperature and works better for high-pressure situations in tough industrial settings.

Can you safely use A106 Grade B lines to carry fluids that eat away at materials?

A106 Grade B carbon steel resists corrosion fairly well, but how well it works with corrosive fluids depends on the chemicals involved and the situations under which they're used. Protective coats or other materials may need to be used in places where corrosion happens very quickly. It is a good idea to talk to materials engineers about certain service situations.

How can people make sure that suppliers are certified and meet high standards?

Buyers should ask for ISO 9001 certification, mill test records, and proof of compliance with ASME. Third-party inspection reports, records of material traceability, and building audit reports show even more proof. Before signing contracts to buy a lot of something, sample testing and pilot orders can show that the seller is capable.

Partner with QinSteel for Superior A106 B Pipe Solutions

With twenty years of experience in the field and a dedication to outstanding quality, QinSteel offers top-notch A106 B pipe options. Our wide range of products, shipping options, and expert support will help your project from specification to installation. We are a reliable A106 B pipe supplier and keep over 10,000 metric tons of approved materials on hand to meet the needs of projects with short schedules. Enjoy the benefits of working with a trustworthy producer who knows what you need for your important equipment. If you want to talk about your exact needs and get good price quotes for your project, email us at info@sxqinsteel.com.

References

American Society of Mechanical Engineers. "ASME B36.10M - Welded and Seamless Wrought Steel Pipe." ASME International Standards, 2018.

ASTM International. "ASTM A106 Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service." Annual Book of ASTM Standards, Volume 01.01, 2019.

American Petroleum Institute. "API 5L Specification for Line Pipe - Comparison with ASTM A106 Applications." API Publishing Services, 2020.

Industrial Piping Systems Handbook. "Carbon Steel Pipe Selection and Application Guidelines for Process Industries." McGraw-Hill Professional Engineering, 2017.

Materials Performance Institute. "High-Temperature Service Applications of Carbon Steel Seamless Pipes in Power Generation." Journal of Industrial Materials Science, Volume 42, 2021.

International Association of Oil & Gas Producers. "Pipeline Materials Standards and Specifications for Upstream Operations." IOGP Technical Guidelines, Report 435-2, 2019.