A105 forged steel flanges are important parts of piping systems. They are made from carbon steel that meets ASTM A105 standards and are meant for industrial settings where there are high pressures and high temperatures. These flanges are made using closed-die forging, which makes them stronger than flanges that are cast. This makes them very important in the oil and gas, industrial, power generation, and water treatment industries. Forged steel flanges are great at sealing pipes because they have great tensile strength and thermal resistance. They are used in plumbing systems where safety and performance are very important.

Understanding A105 Forged Steel Flanges

Material Composition and Properties

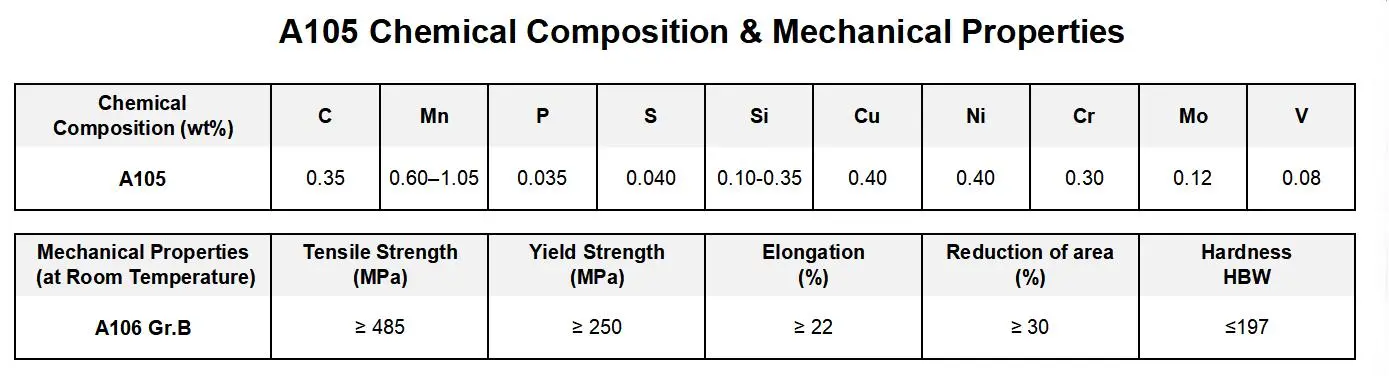

ASTM A105 carbon steel has a carefully balanced mix of chemicals that makes it perfect for forged flange uses. It usually has 0.35% or less carbon, 0.60% to 1.05% manganese, 0.035% or less phosphorus, and 0.040% or less sulfur. This exact science makes sure that it's easy to weld and that it stays very strong mechanically.

During forging, the steel is bent in a controlled way at high temperatures and pressures. This improves the grain structure and gets rid of flaws that are usually found in materials that are made from metal. This way of making things leads to better mechanical qualities. For example, tensile strength is between 70,000 and 95,000 psi, and yield strength is at least 36,000 psi.

Manufacturing Excellence Through Forging

Closed-die forging technology transforms raw steel billets into precision-engineered flanges through a series of controlled heating and shaping operations. The process starts by heating the steel to about 2100°F. Then, it is shaped in stages in specially designed dies that make the exact flange pattern that is needed.

This way of making things works a lot better than other ways of making them. During forging, a continuous grain flow is created through the flange body. This gets rid of any weak spots and makes sure that the stress is spread evenly when loads are applied. Also, forging makes the microstructure dense, which helps the metal survive wear and stress corrosion cracking.

Key Dimensions and Grades of A105 Forged Steel Flanges

Standard Size Ranges and Pressure Classifications

Flanges made from carbon steel that meet the A105 standards come in a wide range of sizes, from 1/2" to 60" (DN15 to DN1500). This makes them useful for a variety of pipe systems. Each of the pressure levels, ranging from 150lb to 2500lb, is made to safely handle certain pressures and temperatures.

Standard thickness plans show pipes from Sch5s to XXS, which gives people choices for different needs in wall thickness. The flange facing choices include raised face (RF), flat face (FF), ring type joint (RTJ), male and female (M&F), and tongue and groove (T&G) settings to meet different sealing needs.

Flange Types and Configurations

A105 material is very useful because it can be used to make many different kinds of flange types for different applications. Here are the most important settings that you can use:

- Weld Neck Flanges: These have a long, tapered hub that spreads stress very well and is perfect for high-pressure situations where resistance to wear is important.

- Slip-On Flanges: These are cheap forged A105 steel flanges for uses with lower pressure. The pipe slides into the flange bore before welding.

- Socket Welding Flanges: Made for pipes with smaller diameters; they make strong links using socket welding.

- Blind Flanges: These can be hub-shaped or flat and are used to seal the ends of pipes or holes in vessels.

- Threaded Flanges: make it possible to connect parts without soldering, which is good for uses where it's necessary to take things apart easily.

Engineers are able to choose the best flange type because these different configurations make it possible for them to take into account unique pressure needs, installation issues, and maintenance factors.

Comparing A105 Forged Steel Flanges with Alternative Materials

Performance Against Stainless Steel Options

There are a few important things to keep in mind when looking at carbon steel A105 flanges next to stainless steel ones, like A182 F304 or F316. Stainless steel flanges prevent rusting much better than A105 flanges, but A105 flanges are a great buy for situations where rust isn't a big problem or can be avoided with a protective coating.

The cost benefit of A105 material is especially important in big projects that need hundreds or thousands of flanges. Carbon steel flanges usually have about the same mechanical strength as similar stainless steel parts, but they cost 40% to 60% less.

Advantages Over Cast and Welded Alternatives

Forged A105 flanges work better than cast steel or welded flange options. The forging process gets rid of the holes and impurities that are common in cast materials. This makes the mechanical properties more reliable and improves reliability when the material is loaded and unloaded repeatedly.

When metal is forged, the grains all line up in the same direction. This makes the metal tougher, which is very important for uses that have to deal with thermal cycles or mechanical vibration. Forged A105 steel flanges are the most popular choice for important uses because this strength leads to longer service life and less need for upkeep.

Procurement Guide: How to Buy the Right A105 Forged Steel Flange

Quality Assurance and Certification Requirements

If you want to get carbon steel flanges, you need to pay close attention to quality standards and licensing requirements. All flanges should meet the ASME B16.5, B16.47, API 6A, or EN 1092-1 standard based on how they will be used and what people in the area like.

Mill test certificates, material traceability records, and dimensional inspection certificates are all very important papers. For very important uses, extra tests may be needed to make sure that the parts are reliable. These tests could be ultrasound examination, magnetic particle inspection, or hardness verification.

Supplier Evaluation and Selection Criteria

Choosing the right source isn't just about price; there are a lot of other things to think about too. Long-term project success depends on the ability to make things, the way quality is controlled, delivery performance, and expert support services. Suppliers should show that they follow ISO 9001 quality management standards and keep the right licenses for the places they want to sell to.

During the procurement process, think about suppliers that offer a wide range of services, such as making custom products, quick delivery, and expert support. Being able to give samples for testing and approval can greatly lower the risks of a project and make sure that it works with current systems.

Practical Applications and Industry Use Cases of A105 Forged Steel Flanges

Oil & Gas Industry Applications

The oil and gas industry is the biggest buyer of A105 forged flanges. They use them in upstream drilling activities, midstream transportation systems, and downstream refining facilities. The flanges need to be able to handle pressures over 1,000 psi and keep seals that don't leak in places with hydrogen sulfide, fuels, and other difficult materials.

Forged flanges are strong and reliable, which makes them especially useful for offshore platforms. If a part on an offshore platform fails, it could have terrible effects on the environment and on safety. Being able to set your own size and pressure rating provides the best performance in special situations.

Power Generation and Industrial Applications

Power companies depend on high-pressure steam systems that use A105 flanges to connect important parts like boilers, turbines, and heat exchangers. Forged carbon steel can handle high temperatures and thermal shock, so these flanges are great for uses that work with temperatures up to 800°F.

These flanges are used in the pipes of chemical plants that work with different chemicals and solvents. The material's ability to apply protective coatings and work with other materials makes it last longer in slightly corrosive environments while still being cheaper than alloys that are rare or hard to get.

Conclusion

Due to their exceptional mix of strength, dependability, and affordability, A105 forged steel flanges continue to be the cornerstone of industrial piping systems in many different industries. When parts are made by forging instead of casting or welding, they get better mechanical qualities. This makes them the best choice for high-pressure situations where safety and performance are very important. Procurement workers need to know about material properties, dimensional standards, and application requirements so they can make good choices that help their projects meet both performance and budget goals.

FAQs

What requirements are met by A105 forged steel flanges?

A105 forged steel flanges meet the ASTM A105 standards for material and a number of measurement standards, including ASME B16.5, B16.47, API 6A, EN 1092-1, and JIS B2220 for dimensions. These guidelines make sure that no matter the purpose or location, there is consistent quality, accuracy in size, and dependable performance.

Can you use A105 forged steel flanges in places where things get corrosive?

A105 carbon steel has great mechanical qualities, but it doesn't hold up against rust as well as stainless steel does. Protective coatings or galvanizing can make things last longer in slightly corrosive settings. For uses that involve very corrosive materials, stainless steel types such as A182 F316 might be a better choice.

How long in advance do you usually have to order special A105 forged steel flanges?

The amount of time you have to wait for custom A105 flanges is usually between 15 and 25 days for normal changes, based on how many flanges you want and how hard the changes are. Flanges of standard size that are in stock can often be sent out in 3 to 5 business days. It can take 4 to 6 weeks to make and try custom complex designs.

Partner with QinSteel for Premium A105 Forged Steel Flanges

QinSteel makes the best A105 forged steel flanges for tough industrial uses in the oil and gas, power generation, and chemical processing sectors. We can make products of all sizes, from 1/2" to 60," with pressure values up to 2,500 lb. All of our products are certified for quality by organizations around the world. We can be trusted to help with your projects because we have been exporting goods for 20 years and have stores in the region for quick delivery. As a reliable producer of A105 forged steel flanges, we offer great prices on bulk orders, custom OEM solutions, and full expert support. Email us at info@sxqinsteel.com to talk about your needs and learn how our high-quality flanges can help your project succeed.

References

American Society of Mechanical Engineers. "ASME B16.5 Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard." ASME Press, 2020.

ASTM International. "ASTM A105/A105M Standard Specification for Carbon Steel Forgings for Piping Applications." Annual Book of ASTM Standards, 2021.

Brozda, Jacek. "Engineering of Steel Forgings." Materials Science Forum, Vol. 426-432, Trans Tech Publications, 2019.

American Petroleum Institute. "API 6A Specification for Wellhead and Christmas Tree Equipment." API Publishing Services, 2018.

European Committee for Standardization. "EN 1092-1 Flanges and Their Joints - Circular Flanges for Pipes, Valves, Fittings and Accessories." CEN Brussels, 2018.

Singh, Rajesh Kumar. "Forged Steel Components in High Pressure Applications: Material Selection and Performance Analysis." Journal of Pressure Vessel Technology, Vol. 142, Issue 3, 2020.