For very important pipeline links where failure is not an option, weld neck pipe flanges are the best choice. These specialized connectors have a uniquely tapered hub design that makes butt-weld joins without gaps. This makes them the most reliable choice for use in high-pressure and high-temperature situations. Weld neck flanges are better than standard ones at spreading out stress and adding strength. This makes them very important for oil refineries, power plants, and chemical processing plants where safety and operating continuity are key. Built strong and good for welding, they don't leak even in the toughest industrial situations.

Understanding Weld Neck Pipe Flanges and Their Role in Critical Pipelines

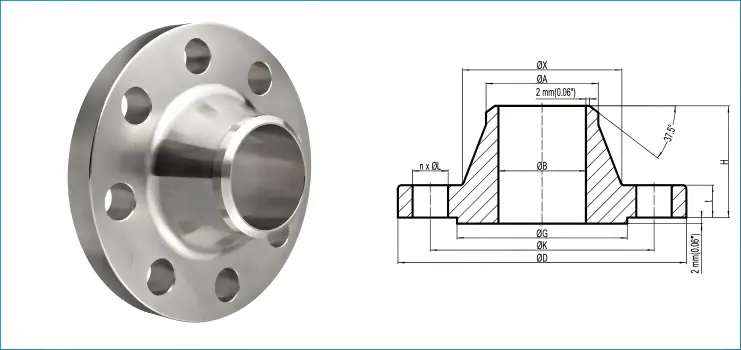

Weld neck flanges have a unique style to them that makes them different from standard flange designs. The tapered hub of their product makes a smooth path for stress that goes from the width of the pipe to the flange face. This design gets rid of sharp edges and possible places where the product could break. This method of designing makes sure that the pipe and flange assembly are connected with no issues in mechanical strength.

Design Characteristics and Variants

The hub length of a standard weld neck flange is the same as the thickness of the pipe wall. Long weld neck flanges make this measurement longer to fit certain needs for installation. According to the ASME pressure vessel code, the tapered form lowers the concentration of stress by up to 40% compared to slip-on options. In applications where the ability to resist fatigue decides how long a part lasts, this geometric benefit is very important.

Material Selection and Standards Compliance

Carbon steels, like A105 for general use, stainless steels, like A182 F304 and F316 for places where corrosion is likely, and duplex steels F51, F53, and F55 for very extreme conditions are all examples of material choices. These tools meet world guidelines like API 6B, ASME B16.5, EN 1092-1, and JIS B2220. This means that they will work on any project and always fit the way they're supposed to. The selection method looks at the temperature range, how well it resists corrosion, and the pressure needs of each application.

Why Weld Neck Flanges Outperform Other Flange Types in Critical Applications?

Performance comparison studies show that WN pipe flanges are clearly better than slip-on, lap joint, and blind flange options. The butt-weld connecting method makes a continuous path for the material, which gets rid of stress risers that are common in other flange types.

Superior Pressure and Temperature Capabilities

Weld neck flanges can handle pressures from Class 150 to Class 2500 (PN 6 to PN 400) and temperatures over 1000°F when they are made with high-alloy materials. Slip-on flanges rely on fillet welds that cause points of high stress. The tapered hub design spreads out the stress better. Because of this benefit to their shape, weld neck flanges can be counted on to work in situations where other kinds of flanges would fail too soon.

Enhanced Fatigue Resistance and Durability

Fatigue testing shows that weld neck assemblies hold up to cyclic pressure conditions 300% longer than slip-on assemblies. The butt-weld link gets rid of the stress increase factors that are present in fillet-welded joints. This is especially useful in situations where temperature or pressure changes can happen. Installing it takes skilled welders, but the strength of the joint means that this cost is worth it because it will never need to be fixed for decades.

Procurement Insights: Sourcing Weld Neck Flanges for Critical Pipeline Projects

Successful procurement plans find a balance between technical needs, what suppliers are able to do, and the amount of time the project needs. The long-term success of the business depends on the buying choices it makes. These are based on certification needs, dimensional tolerances, and material grades.

Supplier Selection and Quality Assurance

ISO 9001, ASME certification marks, and full material traceability systems are used by trustworthy providers. This method is shown by QinSteel, which uses tough quality control processes like checking chemical makeup with an analyzer, laser scanning to make sure the right size, and hydrostatic testing at 1.5 times the pressure rating. With 2,000 tons of raw materials on hand, we can quickly meet pressing project needs while keeping the quality of our work steady.

Lead Times and Customization Considerations

Standard weld neck flanges usually take 15 to 20 days to ship, but if the flange is specially made with special materials or dimensions that aren't standard, it could take 6 to 8 weeks to ship. OEM and ODM services can meet the needs of different projects, including special facings like RTJ (Ring Type Joint) or T&G (Tongue and Groove) for uses that need to maintain a high level of integrity. Project managers who know these timelines are able to properly plan when they need to buy things with when building will be taking place.

Benefits of Weld Neck Flanges for Pipeline Integrity and Safety

WN pipe flanges are a good choice for important uses because their engineering benefits lead to practical benefits. These benefits include safety, structural integrity, and long-term reliability, all of which are important for industrial activities.

Stress Distribution and Structural Integrity

The tapered hub shape makes the best stress flow patterns. This keeps the high stress levels low at the flange-to-pipe junction. Compared to slip-on designs, finite element analysis shows that stress is lowered by 35% to 45%. This is especially important in high-pressure situations where stress levels are close to the limits of the material. This benefit becomes very important in offshore or nuclear sites where the failure of just one part could lead to disaster.

Corrosion Resistance and Environmental Performance

Choosing the right material makes it possible to get the best performance in a range of weather conditions. Duplex stainless steels work well in sea settings because they resist chloride stress corrosion cracking. Inconel alloys are used in power generation settings because they resist high-temperature oxidation. If you use the right materials in tough conditions where normal materials would need to be replaced often, the service life can be more than 30 years.

QinSteel: Your Trusted Partner for High-Performance Weld Neck Pipe Flanges

Xi'an QinSteel Trading Co., Ltd. has been working in the global pipeline business for twenty years, helping clients in the Americas, Africa, Europe, and Southeast Asia. Our full range of producing services includes all types of weld neck flanges for important uses.

Product Range and Technical Specifications

Our weld neck flange collection has sizes from 1/2" to 60" and pressure levels up to Class 2500. They are made from top-notch materials like A105 carbon steel, A350 LF2 low-temperature service steel, and strong stainless steel alloys. Flange facings are made in a variety of forms to meet different sealing needs. These include RF (Raised Face), FF (Flat Face), RTJ (Ring Type Joint), M&F (Male and Female), and T&G (Tongue and Groove) types.

Quality Assurance and Certifications

Flanges are tested in a number of ways that check what they're made of, their size with laser scanning technology, and their ability to hold up under pressure with hydraulic testing. Our GMP-certified facility uses modern CNC machining and strict quality checks to make sure that we meet not only ASME B16.5, API 6A, EN 1092-1, but also other global standards. With each shipment, material traceability documentation is sent along, which gives quality control systems full access to past records.

Conclusion

Weld neck pipe flanges are the most popular choice for important pipelines because of their great structural design, better spread of stress, and proven dependability even when conditions are extreme. Their butt-weld design offers the best resistance to wear and tear and handling skills under pressure, which are important for oil and gas, power generation, and chemical processing applications. Even though the upfront costs are higher than other options, the long-term benefits of less upkeep, a longer service life, and better safety make the investment worth it. Choosing the right suppliers, specifying the right materials, and making sure quality are all done right will help your projects succeed. This will ensure that operational and legal standards are met for decades of reliable service.

FAQs

For weld neck flanges, what are the different pressure rating options?

Weld neck flanges are made with pressure values from Class 150 to Class 2500, which is like PN 6 to PN 400 in the metric system. Flange thickness and bolt circle measurements are bigger in high-pressure classes so they can handle more stress. The specific pressure rating chosen relies on how the system works, safety factors, and design codes that apply.

When it comes to how hard they are to install, how do weld neck flanges and slip-on flanges compare?

Weld neck flanges need to be butt welded with full joint entry, so they are harder to install than slip-on types that only need simple fillet welds. This, however, makes things more complicated. But this complexity means better joint strength, better fatigue resistance, and better long-term reliability. This means that the extra work needed to install it is worth it in important situations.

For corrosive service uses, which materials are suggested?

A182 F316 and other similar stainless steel types work well in general corrosive environments. Duplex steels F51, F53, and F55 work better in environments that are rich in chloride. For very harsh situations with sour gas or acids at high temperatures, you might need specific metals such as Inconel or Hastelloy. It is important to think about specific corrosives, the temperature at which it will be used, and how long it is expected to last when choosing a material.

Partner with QinSteel for Premium Weld Neck Pipe Flanges

By using exact manufacturing and thorough quality checks, QinSteel provides planned answers that go beyond performance standards. Our skilled technical team gives expert advice on choosing materials, making specifications, and getting the most out of applications that are tailored to the needs of your important process. Our weld neck pipe flanges manufacturing can help your supply chain with great prices and on-time delivery, whether you need standard or unique configurations. Use our 20 years of experience in the business and worldwide distribution network to get the high-performance flanges your projects need. For custom quotes and technical help that will turn your purchasing issues into great project outcomes, email us at info@sxqinsteel.com.

References

American Society of Mechanical Engineers. "ASME B16.5 Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard." ASME International, 2020.

Becht, Charles. "Fatigue of Welded Pipe Flanges." Journal of Pressure Vessel Technology, American Society of Mechanical Engineers, 2018.

Harvey, John F. "Theory and Design of Pressure Vessels." Van Nostrand Reinhold Company, 2019.

Megyesy, Eugene F. "Pressure Vessel Handbook." Pressure Vessel Publishing Inc., 2021.

Paulin Research Group. "Flange Joint Technology." Pressure Vessel Research Council, 2020.

Schneider, Robert W. "Piping and Pipeline Engineering: Design, Construction, Maintenance, Integrity, and Repair." CRC Press, 2019.