When procurement professionals look at piping options for important industrial uses, they need to know the differences between ASTM A106 Grade B and A53 pipes. The A106 B pipe is a seamless carbon steel option designed for use in settings with high temperatures and pressures. The A53 pipe, on the other hand, is more versatile because it comes in both welded and seamless forms. In tough industrial areas, these material standards have a direct effect on how well a project runs, how much compliance it costs, and how much it costs to own overall.

Introduction to A106 Grade B and A53 Pipes

The different material properties and manufacturing requirements for ASTM A106 Grade B and ASTM A53 pipes mean they have different uses in industry. A106 Grade B pipes, mostly without seams, are made to be used at high temperatures and with high pressures. On the other hand, A53 pipes come in both welded and seamless types in Grades A, B, and C. This gives you more options for general structural and piping needs.

Overview of ASTM A106 Grade B Pipe

ASTM A106 Grade B is a standard for a seamless carbon steel pipe that is meant to be used in high-temperature conditions. The material is made of carbon (no more than 0.30%) and manganese (0.29% to 1.06%), giving it outstanding mechanical qualities. These pipes have a tensile strength of at least 415 MPa and a yield strength of at least 240 MPa. This makes them a good choice for power generation facilities, petrochemical processing units, and oil plants where they will be subjected to high temperatures and pressures.

Overview of ASTM A53 Pipe

ASTM A53 includes more types of carbon steel pipes that come in welded and non-welded versions. These pipes are sorted into three grades: A, B, and C. Grade B is the most frequently requested version because it has balanced mechanical properties that make it good for general structural use. The specification allows for both electric resistance welded (ERW) and seamless manufacturing methods. This gives buyers the freedom to choose based on how they plan to use it and how much they want to spend.

Why Understanding the Differences Matters for Procurement?

Choosing the right pipe design has a direct effect on how well a project runs, whether it follows the rules, and how much it costs in the long run. Procurement choices affect the ease and speed of installation and upkeep needs across the entire asset lifecycle. Understanding these differences in materials allows you to make smart choices that find a balance between how well the technology works and how well it sells.

Technical Comparison: Material Specifications and Properties

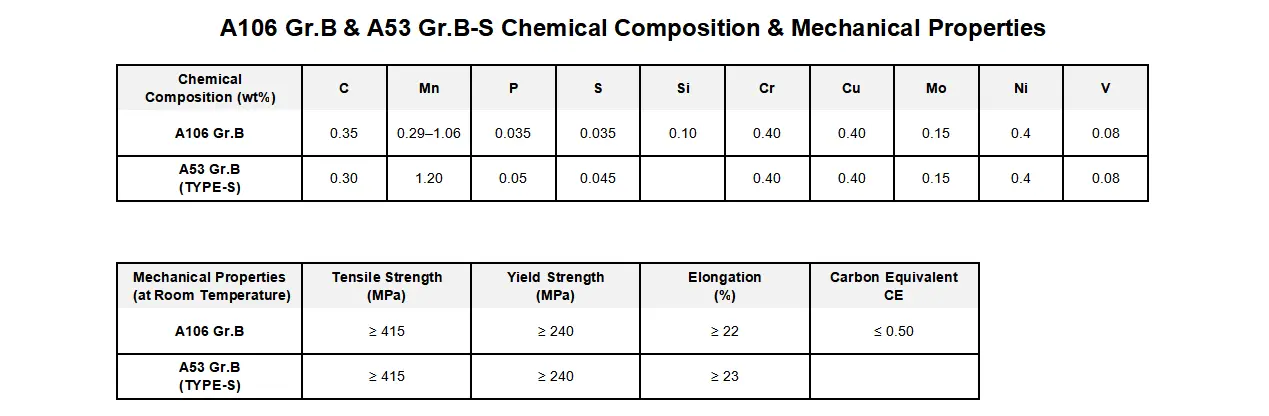

This part goes into great depth about the chemical and mechanical properties that make pipes of A106 Grade B and A53 different from each other. It shows how key alloying elements affect welding and performance, and it makes direct comparisons of strength and size standards.

Chemical Composition Differences

The different chemicals in A106 Grade B and A53 Grade B pipes make them work in different ways. A106 Grade B keeps a closer eye on the amount of silicon in it (at least 0.10%), which improves stability at high temperatures when compared to A53 standards. In A106 Grade B, the amount of phosphorus and sulfur can't be more than 0.035% for each. This makes it easier to weld and less likely to suffer from hot cracking during manufacturing.

Mechanical Properties Breakdown

The differences in mechanical properties show us how each specification can work better. A106 Grade B has better tensile strength (at least 415 MPa) than A53 Grade B (at least 400 MPa), but both have the same yield strength standard of 240 MPa or more. The elongation properties of A106 Grade B make it more ductile, which helps with temperature cycling and mechanical stress. Because of these qualities, A106 B seamless pipes are especially good for boiler tubes, superheater tubes, and high-pressure steam lines.

Dimensional Standards and Tolerances

ASTM A106 and A53 standards have different physical requirements that affect how easy it is to make the parts and how suitable they are for different uses. A106 pipes follow the ASME B36.10M standards with less flexibility for wall thickness, which makes sure they always work under pressure. Because seamless A106 pipes don't have longitudinal welds, there are no possible weak spots. The dimensional stability of the pipes means that the strength is the same all the way through the pipe wall.

Performance and Application Suitability

A106 Grade B and A53 pipes have different operational ranges. These ranges are based on performance measures like pressure ratings, temperature resistance, and how well the pipes fight corrosion. Understanding these features helps procurement workers find the right materials for the right jobs.

Pressure Ratings and Temperature Resistance

A106 B pipe is great for high-pressure situations, with working pressures of up to 3,000 PSI based on the thickness of the wall and the temperature. The seamless construction gets rid of weaknesses at the weld seam, so it can be used in pressure services where dependable performance is very important. The temperature resistance ranges from -29°C to 425°C, which works for very hot and very cold conditions in the power production and process industries. A53 pipes usually work in applications with lower pressure and temperature limits that depend on the grade and wall thickness standards.

Corrosion Resistance and Durability

Both standards show that they can protect carbon steel applications from corrosion, but the conditions in which they are used have a big impact on how well they work. A106 Grade B's controlled chemistry makes it better able to fight scaling and oxidation at high temperatures. Protective coatings and surface treatments can help things last longer in settings where they can get damaged by chemicals. When choosing materials, the conditions they will be used in and how easy they will be to maintain should be kept in mind.

Welding and Installation Considerations

Because the chemicals and production processes are not the same, A106 Grade B and A53 pipes need different welding methods. A106 Grade B needs to be preheated for thicker parts, and it keeps certain interpass temperature limits to avoid cracking. Because there are no joints to worry about, seamless A106 pipes make field welding easier since you don't have to think about how the weld seam is oriented or how the heat-affected zone interacts with welds that are already there.

Procurement Considerations: Cost, Availability, and Lead Time

Good procurement depends on looking at price trends, source reliability, and logistical factors. A106 B seamless pipes made from ASTM A106 Grade B usually cost more than A53 pipes because they need to perform better and must be made without seams.

Price Comparison and Market Analysis

Right now, A106 Grade B is more expensive than A53 options because of the special ways they are made and better performance. Strategies for buying in bulk can make sure that each unit doesn't cost too much and that there is enough stock on hand for the needs of the project. Changes in regional prices rely on how much can be made, the cost of shipping, and how much demand there is in the area. These factors affect how people decide to buy things.

Supplier Landscape and Quality Assurance

Top producers keep long certification programs that make sure they can track the source of their materials and meet quality standards. QinSteel shows this dedication by getting ISO 9001 certification, following the PED rules for the European market, and getting CSA permission for use in Canada. For every production batch, our quality control methods include hydrostatic testing, ultrasonic inspection, and radiographic examination. This makes sure that the performance is always reliable in important applications.

Lead Time Optimization

Delivery times depend on how complicated the specifications are, how many items are needed, and which areas have the items in stock. Because there are set ways of doing things in A106 Grade B, standard sizes have shorter lead times and special sizes may have to wait longer. QinSteel keeps more than 10,000 metric tons of strategic inventory on hand so that regional delivery centers can quickly meet the needs of urgent projects.

How to Choose Between A106 Grade B and A53 Pipe: A Procurement Guide

This methodical way of doing things helps buying experts look at what a project needs and find a balance between how well the project can be done technically and how much it will cost. Choosing the right materials for a job not only gets the best long-term results for the money spent, but it also lowers the risk of having to make costly repairs.

Defining Project Requirements

The test starts by figuring out the situations in which it will have to work, such as the highest pressure, the temperature range, and the effects of the environment. Chemical compatibility, mechanical loading, and regulatory compliance standards set the most basic rules for material evaluation. Keeping a record of these factors makes it possible to correctly compare A106 Grade B to A53.

Performance Evaluation Criteria

While taking the price and availability into account, the weighting factors should focus on the most important performance features. A106 Grade B standards are usually better for high-pressure applications, but A53 alternatives may be used for general structural purposes. A106 pipes are worth the high price in important service uses where the effects of failure are bad because they can be made without seams.

QinSteel: Your Trusted A106 B Pipe Manufacturer

QinSteel specializes in manufacturing premium ASTM A106 Grade B seamless pipes backed by rigorous quality assurance and global certification compliance. Our wide range of products comes in sizes from 1/8" to 80" (10.3 mm to 2032 mm) and with wall thicknesses from Schedule 5S to XXS, meeting a variety of needs in different industries.

The carbon content in our seamless carbon steel pipes is kept at a maximum of 0.30%, and the manganese level is between 0.29% and 1.06%. This makes the pipes work better than others. The way it's made guarantees a tensile strength over 415 MPa and a yield strength over 240 MPa. These beat tough industry standards for important uses.

Quality assurance includes hydraulic pressure testing, ultrasonic inspection, radiographic examination, and other tests. Full material certification is given to every production batch. This shows the chemical makeup, mechanical qualities, and compliance with dimensions. ISO 9001, PED, and CSA approvals all show that our sites are ready for business in markets around the world.

Conclusion

Understanding the important differences between A106 Grade B and A53 pipes gives procurement workers the power to make choices that improve project performance and save money. The seamless structure and controlled chemical composition of A106 B pipe make it work better in high-temperature, high-pressure settings. A53 pipes are useful for a range of general structural and moderate pressure uses because they are flexible to make and cheap to use. To make sure a long-term project goes well, the working conditions, performance needs, and commercial factors must be carefully looked at when choosing a material.

FAQs

Is it possible to use A106 Grade B pipe instead of A53 pipe without making any other changes?

A106 Grade B usually has better mechanical qualities and is made without seams, so it can be used instead of A53 Grade B in most cases. But before making a replacement, its project's needs, cost, and pressure grades should be checked. A106 Grade B's better performance may give extra safety gaps in very important uses.

For A106 Grade B pipe, what are the most important checking tests?

Standard inspection needs hydrostatic pressure testing, ultrasonic examination for internal flaws, dimensional verification, and chemical makeup analysis. Radiographic inspection, hardness testing, and impact testing are extra tests that may be done based on the needs of the application and the directions from the customer.

What are the differences between A106 Grade B and A53 lines when it comes to welding?

A106 Grade B usually needs to be preheated for parts that are thicker than a certain amount and has tighter interpass temperature controls because of controlled chemistry. The way that someone welds, such as how much heat is used, how fast it cools, and if heat is applied after welding, can change depending on the thickness and material that is being used. Both sets of instructions mostly use the same welding materials and methods, but they change them to fit different science needs.

Contact QinSteel for Expert A106 B Pipe Solutions

Are you ready to find high-quality A106 B pipe options for your next job? QinSteel can meet your important piping needs because they have been in the business for 20 years and have a large inventory. Our seamless pipes are used successfully in oil and gas, power generation, and chemical processing uses around the world. Get in touch with our technical team if you need a unique quote, want to buy a lot and get the best price, or want to get your order quickly. To see all of our A106 B pipe specifications and possibilities, email us at info@sxqinsteel.com.

References

ASTM International. "Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service." ASTM A106/A106M-19a.

ASTM International. "Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless." ASTM A53/A53M-20.

American Society of Mechanical Engineers. "Process Piping: ASME Code for Pressure Piping, B31." ASME B31.3-2020.

Metals Handbook Committee. "Properties and Selection: Irons, Steels, and High-Performance Alloys." ASM International Handbook Volume 1.

Beavers, J.A. and Thompson, N.G. "External Corrosion of Oil and Natural Gas Pipelines." Corrosion: Fundamentals, Testing, and Protection, ASM Handbook Volume 13A.

Kiefner, J.F. and Maxey, W.A. "Pipeline Integrity Management Systems: A Practical Approach." American Gas Association Operations Section Proceedings.