- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Weld Neck Pipe Flanges

Xi'an QinSteel Trading Co., Ltd | High-Performance Weld Neck Pipe Flanges for Demanding Industrial Systems

When you need leak-proof connections for high-pressure pipelines, Weld Neck Pipe Flanges deliver unmatched reliability. At Xi’an QinSteel, we specialize in manufacturing flanges that meet ASME B16.5, API 6A, and EN 1092-1 standards, backed by 15+ years of expertise in serving oil, gas, and power industries. Our GMP-certified facility combines advanced CNC machining with rigorous quality checks to ensure every flange withstands extreme temperatures and pressures.

Durable Weld Neck Flanges Built for Critical Applications

Our products are engineered to optimize stress distribution in piping systems, minimizing failure risks in corrosive or high-vibration environments. With sizes from ½" to 60" and pressure ratings up to Class 2500 (PN 400), they’re ideal for:

- Oil & Gas Pipelines: Offshore platforms, refinery transfer lines

- Power Plants: High-temperature steam systems

- Chemical Processing: Corrosion-resistant alloy solutions

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN 15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Custom sizes, RTJ/T&G facings, and coatings available via OEM/ODM services.

Why Our Weld Neck Flanges Outperform?

1. Global Compliance, Local Reliability

Every flange undergoes material traceability checks and non-destructive testing (NDT) to comply with API, ASME, and PED standards for Weld Neck Pipe Flanges.

2. Precision Engineering

Tapered hub designs reduce stress concentration, while smooth bore surfaces prevent turbulence in fluid flow.

3. Rapid Order Fulfillment

Leverage our 2,000-ton raw material inventory for urgent orders – bulk shipments ready in 15–20 days.

4. Corrosion Defense

Choose duplex steel (F51/F53) or Inconel coatings for sour gas or seawater applications.

Trusted by Global Partners

Industries We Serve:

- Oil & Gas: API 6A wellhead flanges with NACE MR-0175 compliance

- Petrochemicals: PTFE-coated flanges for acid transport

- Water Treatment: EN 1092-1 certified flanges for municipal systems

Quality Assurance Steps

1. Material Testing: Spectrometer verification of chemical composition

2. Dimensional Checks: Laser scanning for ASME B16.5 tolerances

3. Pressure Validation: Hydrostatic testing at 1.5x rated pressure

Quality Control

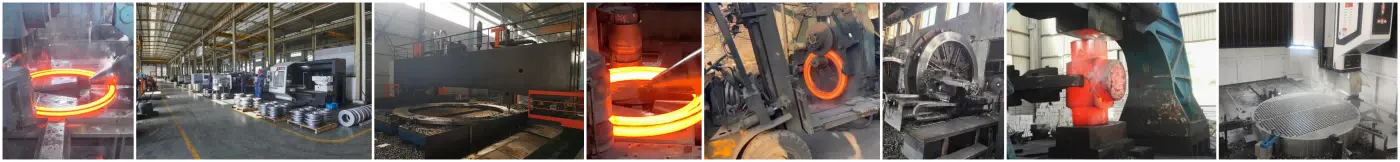

Factory Equipment

Shipping Packaging

FAQ: Your Weld Neck Flange Questions Answered

Q: Can you provide flanges for a Class 1500 hydrogen pipeline?

A: Yes. We recommend A350 LF2 material with RTJ facings – MOQ 10 units.

Q: Do you offer NACE certifications?

A: All sour service flanges include NACE MR-0175 test reports.

Q: How are flanges protected during shipping?

A: Wooden crates with VCI anti-corrosion paper and edge guards.

Q: What’s the lead time for 100 custom WN flanges?

A: 12–18 days with expedited production.

Contact Us

Email your specifications to info@sxqinsteel.com for Weld Neck Pipe Flanges:

- Instant pricing for bulk orders

- Material test certificates

- CAD drawings for custom designs

GMP-Certified | API/ASME-Compliant | ISO 9001:2015

Learn about our latest products and discounts through SMS or email