Understanding A105 Carbon Steel Flanges: Properties and Applications

Composition and Material Properties of A105 Carbon Steel

A105 carbon steel is a low-carbon steel alloy known for its strength and versatility. It typically contains 0.35% carbon, 0.60% manganese, and small amounts of other elements like silicon, phosphorus, and sulfur. This composition gives A105 carbon steel excellent mechanical properties, including high tensile strength and good ductility.

The material's ability to withstand moderate pressures and temperatures makes it suitable for various industrial applications. A105 carbon steel can maintain its structural integrity at temperatures up to 350℃ (662℉), making it ideal for many pipeline and processing systems.

Common Industrial Applications for A105 Carbon Steel Flanges

A105 carbon steel flanges find wide use across numerous industries due to their reliability and cost-effectiveness. Some common applications include:

- Oil and gas pipelines

- Water treatment facilities

- Chemical processing plants

- Power generation systems

- HVAC systems

- General industrial piping

These flanges are particularly well-suited for projects that require moderate pressure ratings and don't involve highly corrosive materials or extreme temperatures.

Advantages of Using A105 Carbon Steel Flanges

Choosing A105 carbon steel flanges for your industrial applications offers several benefits:

- Cost-effectiveness: A105 carbon steel is relatively inexpensive compared to other flange materials, making it an economical choice for large-scale projects.

- Durability: These flanges offer excellent strength and resistance to wear, ensuring long-lasting performance in various industrial environments.

- Versatility: A105 carbon steel flanges are available in a wide range of sizes and pressure ratings, accommodating diverse project requirements.

- Weldability: The material's composition makes it easy to weld, simplifying installation and maintenance processes.

- Availability: Due to their widespread use, A105 carbon steel flanges are readily available from suppliers, reducing lead times for projects.

Factors to Consider When Selecting A105 Carbon Steel Flanges

Pressure and Temperature Requirements

When deciding whether to use A105 carbon steel flanges, it's crucial to consider the operating pressure and temperature of your system. These flanges are suitable for applications with moderate pressure ratings and temperatures up to 350℃ (662℉). For higher pressure or temperature requirements, you may need to explore alternative materials or flange designs.

Always consult with a qualified engineer or flange supplier to ensure that the selected A105 carbon steel flange meets the specific pressure and temperature requirements of your application. This step is critical for maintaining safety and efficiency in your industrial processes.

Corrosion Resistance and Environmental Factors

While A105 carbon steel offers good resistance to general corrosion, it may not be suitable for highly corrosive environments or applications involving certain chemicals. Consider the following factors when assessing the suitability of A105 carbon steel flanges for your project:

- pH levels of the media being transported

- Presence of corrosive chemicals or gases

- Exposure to saltwater or marine environments

- Frequency of cleaning or maintenance procedures

In cases where corrosion resistance is a significant concern, you may need to consider alternative materials such as stainless steel or apply protective coatings to the A105 carbon steel flanges.

Compatibility with Other System Components

Ensuring compatibility between A105 carbon steel flanges and other components in your piping system is essential for optimal performance and longevity. Consider the following aspects:

- Material compatibility: Verify that A105 carbon steel is compatible with the materials used in other parts of your system, such as pipes, valves, and gaskets.

- Galvanic corrosion: Be aware of potential galvanic reactions when connecting A105 carbon steel flanges to dissimilar metals, and take appropriate measures to prevent corrosion.

- Flange face type: Choose the appropriate flange face (e.g., raised face, flat face, or ring-type joint) to match your system requirements and ensure proper sealing.

- Bolt material: Select compatible bolt materials that can withstand the same operating conditions as the A105 carbon steel flanges.

By carefully considering these factors, you can ensure that A105 carbon steel flanges integrate seamlessly with your existing or planned industrial systems.

Best Practices for Installation and Maintenance of A105 Carbon Steel Flanges

Proper Installation Techniques

Correct installation of A105 carbon steel flanges is crucial for ensuring optimal performance and longevity. Follow these best practices during the installation process:

- Clean and inspect: Thoroughly clean the flange faces and inspect for any damage or defects before installation.

- Align properly: Ensure precise alignment between the mating flanges to prevent uneven stress distribution.

- Use appropriate gaskets: Select gaskets that are compatible with A105 carbon steel and suitable for your specific application.

- Apply proper torque: Use a calibrated torque wrench to tighten bolts in a star pattern, gradually increasing torque to the specified value.

- Avoid over-tightening: Excessive torque can damage the flange or compromise the seal integrity.

Proper installation techniques help prevent leaks, extend the life of your A105 carbon steel flanges, and ensure safe operation of your industrial systems.

Regular Maintenance and Inspection Procedures

To maximize the lifespan and performance of A105 carbon steel flanges, implement a regular maintenance and inspection schedule. Key aspects of flange maintenance include:

- Visual inspections: Regularly check for signs of corrosion, wear, or damage to the flange surface.

- Bolt tension checks: Periodically verify that bolts maintain proper tension to prevent leaks.

- Gasket replacement: Replace gaskets during scheduled maintenance or if signs of wear or degradation are observed.

- Cleaning: Remove any buildup of debris or corrosion products that may affect flange performance.

- Corrosion monitoring: Implement a corrosion monitoring program to track the condition of A105 carbon steel flanges over time.

By adhering to these maintenance practices, you can significantly extend the service life of your A105 carbon steel flanges and minimize the risk of unexpected failures or leaks.

Troubleshooting Common Issues with A105 Carbon Steel Flanges

Despite their reliability, A105 carbon steel flanges may occasionally encounter issues. Being prepared to address common problems can help maintain system integrity and minimize downtime. Some typical issues and their solutions include:

- Leaks:

- Check for proper bolt torque and retighten if necessary.

- Inspect gaskets for damage and replace if needed.

- Verify flange face condition and resurface if required.

- Corrosion:

- Identify the source of corrosion (e.g., environmental factors or process fluids).

- Apply appropriate protective coatings or consider alternative materials for severely corrosive environments.

- Implement more frequent inspection and maintenance routines in corrosive settings.

- Misalignment:

- Loosen bolts and realign flanges carefully.

- Use alignment tools or laser systems for precise positioning.

- Consider using flexible connectors or expansion joints to accommodate minor misalignments.

By addressing these issues promptly and effectively, you can ensure the continued reliable performance of your A105 carbon steel flanges in various industrial applications.

Conclusion

A105 carbon steel flanges are an excellent choice for industrial applications that require cost-effective, durable, and versatile components. Their suitability for moderate pressure and temperature conditions, combined with good corrosion resistance, makes them ideal for various industries, including oil and gas, water treatment, and general industrial piping. By carefully considering factors such as pressure and temperature requirements, environmental conditions, and system compatibility, you can make an informed decision on when to choose A105 carbon steel flanges for your projects. Remember to follow best practices for installation, maintenance, and troubleshooting to maximize the performance and longevity of these essential industrial components.

FAQs

What are the main advantages of using A105 carbon steel flanges?

A105 carbon steel flanges offer cost-effectiveness, durability, versatility, and good weldability. They are suitable for moderate pressure and temperature applications up to 350℃.

In which industries are A105 carbon steel flanges commonly used?

These flanges are widely used in oil and gas, water treatment, chemical processing, power generation, HVAC systems, and general industrial piping.

How often should A105 carbon steel flanges be inspected?

Regular inspections should be conducted as part of a maintenance schedule, typically annually or more frequently in corrosive environments. Visual checks and bolt tension verifications are essential.

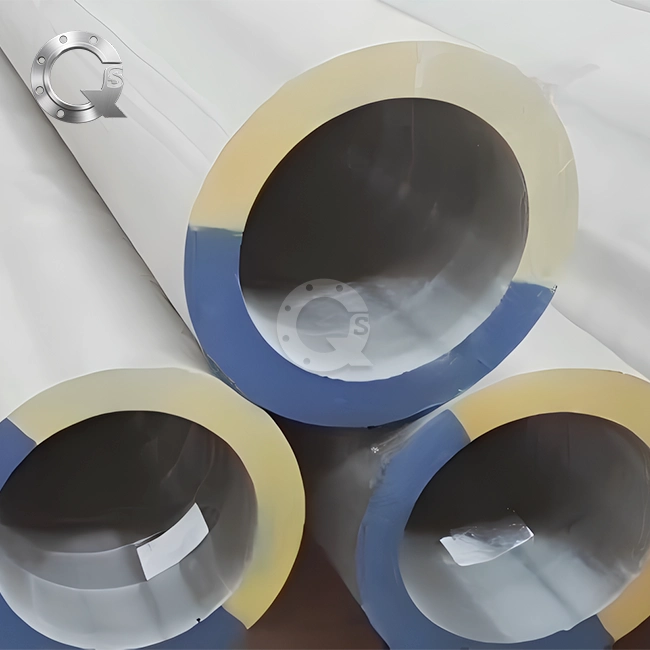

Expert A105 Carbon Steel Flange Solutions | QinSteel

At QinSteel, we specialize in providing high-quality A105 carbon steel flanges for a wide range of industrial applications. With 20 years of industry expertise, our comprehensive product range and commitment to quality make us the ideal supplier for your flange needs. Our experienced team offers expert guidance to help you choose the right flanges for your specific requirements. Contact us at info@sxqinsteel.com to discuss your A105 carbon steel flange needs and experience our superior customer service.

References

Smith, J. (2021). "Industrial Flange Selection: A Comprehensive Guide." Journal of Piping Engineering, 15(3), 78-92.

Johnson, R. & Williams, T. (2020). "Corrosion Resistance of Carbon Steel Flanges in Industrial Applications." Materials Performance, 59(8), 30-35.

Brown, A. (2019). "Best Practices for Installation and Maintenance of A105 Carbon Steel Flanges." Pipeline Technology Journal, 7(2), 45-52.

Davis, M. (2022). "Comparative Analysis of Flange Materials for Moderate Pressure Applications." International Journal of Pressure Vessels and Piping, 201, 104471.

Thompson, L. (2018). "Factors Affecting the Lifespan of Carbon Steel Flanges in Industrial Environments." Corrosion Science, 138, 8-17.

Garcia, E. & Lee, S. (2020). "Advancements in Flange Design for Improved Performance in Oil and Gas Applications." SPE Production & Operations, 35(2), 270-282.