- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What to do if ASME B16.11 Socket Weld Tees Show Welding Joint Corrosion?

Dec 8 2025

If ASME B16.11 socket weld tees have welding joint rust, you should grind off the rusty part of the joint, re-weld it according to standard procedures, and check the pressure to make sure there are no leaks. Making sure the part is safe and whole during this process makes it last longer and keeps the system working well. You need to take care of rust right away so that your pipes don't break or get worse.

Understanding ASME B16.11 Socket Weld Tees and Corrosion Issues

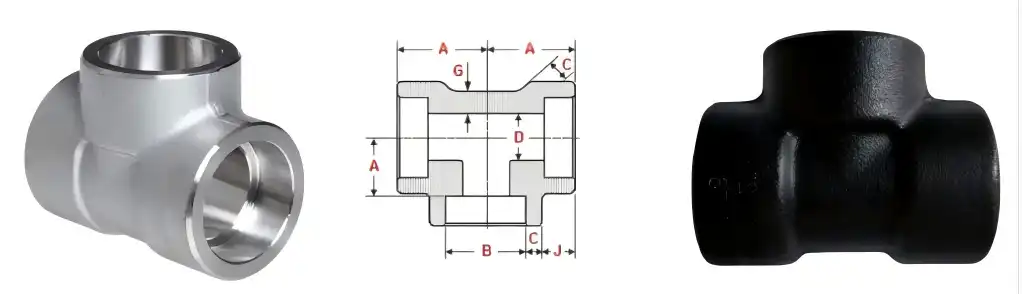

What are ASME B16.11 Socket Weld Tees?

In plumbing systems, ASME B16.11 socket weld tees are useful because they make it easy to connect lines that are not straight. A lot of people use these valves in places with a lot of pressure, like the oil and gas, manufacturing, and power industries. Because they have to meet certain performance, material, and size requirements, the ASME B16.11 standard makes sure that these t-shirts are safe and reliable to use.

Common Causes of Welding Joint Corrosion

Wiring joint rust in socket weld tees can be caused by a number of things. It is possible for the rusting process to speed up if it is near water or acids that eat away at metal. If you don't use enough heat or cover enough protective gas when you weld, you might leave weak spots where rust can easily form. It's also possible for two different metals to rust when they meet, especially if there is an electrolyte around.

The Importance of Early Detection and Intervention

It is very important to find and fix welding joint rust as soon as you see it. This will keep your pipe system in good shape. Regular maintenance and checks can help find rust before it gets worse. If you move quickly, you can stop leaks and other problems before they happen. This also lowers the cost of repairs and cuts down on the time the system is down.

Step-by-Step Guide to Addressing Welding Joint Corrosion

Preparation and Safety Measures

Before you start changing something, it's important to make sure you're safe. Make sure the work area has good air flow and that the system is depressurized and drained. Protect yourself by putting on the right PPE, like safety glasses, gloves, and a mask to protect your face. Gather the things you'll need, like a metal-cutting wheel, soldering gear, and filling material that will work with metal.

Grinding and Surface Preparation

To fix rust in a weld joint, you must first take out the broken part. Be careful to use the right tool or a grinding wheel to remove the rusty part of the welding joint. Before you join it again, make sure to clean up the surface and get rid of any rust that you can see. You shouldn't take off too much material, because that could make the fitting less strong.

Re-welding Process and Quality Control

As required by ASME B16.11 socket weld tees, re-weld the joint after cleaning the surface. Make sure you use the right amount of heat and filling material, and the right welding method, such as GTAW (TIG) or SMAW (stick welding). Look over the piece carefully to see if there are any flaws or problems after you're done joining. You can be even more sure of the quality of your fix with non-destructive testing methods, such as magnetic particle inspection or dye penetrant inspection.

Post-Repair Procedures and Long-Term Maintenance

Pressure Testing and Leak Detection

As soon as the part has been fixed, it's important to test its strength by applying pressure to it. Follow the industry's normal ways of checking pressure and slowly raise it until it meets the system's planned working pressure. Pay close attention to the area that was fixed for any signs of damage or leaks. The part can be used as long as there are no problems.

Implementing Corrosion Prevention Measures

You may want to add more defense to keep rust from happening again. Put the right covers or wraps on the fixed area and the joints around it to keep things that can damage metal even safer. Some conditions may call for cathodic protection systems to lower the risk of rust even more, especially when lines are underground or submerged in water.

Establishing a Regular Inspection and Maintenance Schedule

You can help your ASME B16.11 socket weld tees and general pipe system last a long time by making a plan to check and fix them each month. A lot of visual checks should be done, and non-destructive checking methods should be thought about. Make sure you write down all the checks, fixes, and rust that you see. This will help you see patterns and find problems before they get too bad.

Conclusion

It is very important to keep ASME B16.11 socket weld tees free of welding joint rust so that pipe systems stay safe and work well. Following the steps in this guide - grinding off rusty spots, carefully re-welding, and checking the fittings while they are under a lot of stress - will fix them. Remember that safety is very important. Your pipe system will last a long time and work well if you take strong steps to stop rust and check it often.

FAQs

How often should I look for rust on ASME B16.11 socket weld tees?

Regular inspections should be done, at least once a year or as often as your business needs. But checks might need to be done more often in places where things rust.

How can I fix a socket weld tee that has a lot of rust on it?

If the rust is really bad, it might be better to get a new part than to try to fix the old one. That person can help you figure out how bad the damage is and what the best thing to do is.

What makes rust happen faster in weld joints?

Rust can happen faster in welding parts if they come into touch with acidic chemicals, if different metals react electrically, or if the weather is bad.

Expert ASME B16.11 Socket Weld Tee Solutions | QinSteel

Your ASME B16.11 socket weld tees will be made by QinSteel, so you can count on them. Because we've been in this business for 20 years, we can make things that are well-made, last a long time, and meet standards around the world. We have a lot of goods, so we can promise good choices for a lot of different uses. Send us an email at info@sxqinsteel.com if you need help getting good parts and stopping rust.

References

ASME B16.11-2016: Forged Fittings, Socket-Welding and Threaded. American Society of Mechanical Engineers.

Corrosion in the Petrochemical Industry, Second Edition. ASM International, 2015.

Welding Metallurgy and Weldability of Stainless Steels. John C. Lippold and Damian J. Kotecki. Wiley-Interscience, 2005.

Handbook of Corrosion Engineering, Third Edition. Pierre R. Roberge. McGraw-Hill Education, 2019.

Piping Handbook, Seventh Edition. Mohinder L. Nayyar. McGraw-Hill Education, 2000.

Corrosion Prevention and Control in Water Treatment and Supply Systems. J.E. Singley. Noyes Publications, 1985.

Learn about our latest products and discounts through SMS or email