- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Prevent Leakage of ASME B16.11 Union Fittings?

Dec 8 2025

To keep water systems safe and whole, it is very important that ASME B16.11 union fittings don't leak. To successfully stop leaks, start by checking the gasket for signs of wear, age, or damage on a regular basis. To make sure a tight seal, replace old gaskets right away. Follow the torque rules and twist the union nut with a steady force as you put the fitting together. Plus, make sure the surfaces that meet are lined up right and use the thread oils or lubricants that the manufacturer recommends. It's important to keep ASME B16.11 union fittings in good shape, install them correctly, and use high-quality materials so that they don't leak and last longer in many industrial settings.

Understanding ASME B16.11 Union Fittings and Their Importance

What are ASME B16.11 Union Fittings?

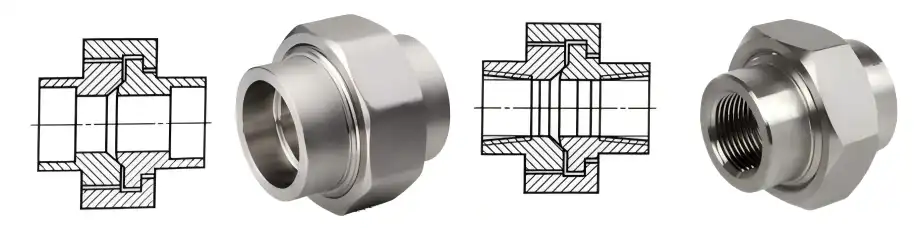

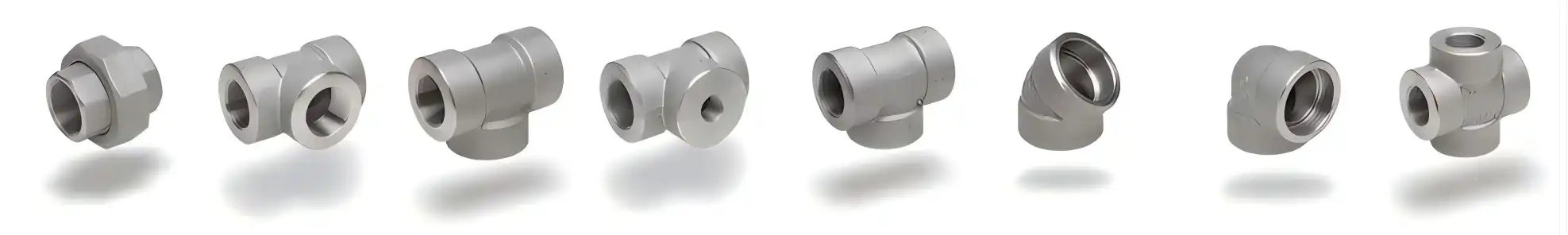

ASME B16.11 union fittings are important parts of water systems because they connect pipes or tubes in a safe and effective way. Some rules about how to make these parts are set by the American Society of Mechanical Engineers (ASME). This makes sure that the standard and accuracy of the business as a whole. Union fittings have three main parts: two end pieces, a union nut, and a middle piece. For repairs and upkeep, this form makes it easy to put together and take apart.

Applications of ASME B16.11 Union Fittings

A lot of businesses use ASME B16.11 union fittings because they are stable and can be used in a number of ways. They are used a lot in places like oil and gas pipelines, chemical companies, and places that treat water. They are great for hydraulic and steam systems because they work well in places with a lot of pressure and heat. It is very important for the safety and efficiency of industrial processes that they can resist tough conditions and keep a leak-free link.

The Importance of Leak Prevention

More than one reason makes it very important that ASME B16.11 union fittings don't leak. In the first place, leaks can waste a lot of stuff, especially in systems that deal with costly or dangerous fluids. Second, they're very risky and could cause accidents or damage to the outdoors. Also, leaks can make systems less effective, raise the cost of maintenance, and stop work. A business can make its processes safer, its systems work better, and its costs of repairs and lost goods go down by focusing on stopping leaks.

Common Causes of Leakage in ASME B16.11 Union Fittings

Gasket Deterioration and Failure

The gaskets wear out over time, which is a major reason why ASME B16.11 union fittings leak. Gaskets are very important for giving the parts a tight seal where their sides meet. A seal can wear out over time if it is exposed to chemicals, changes in pressure, or temperatures that are too high or too low. Because of this, the gasket may harden, crack, or change shape, which makes it less able to close well. It is important to check and change seals often to avoid problems that can happen when they fail.

Improper Installation and Tightening

Most of the time, leaks are caused by bad installation techniques and union fittings that are not tightened enough. It's important to make sure that the matched sides of the ASME B16.11 union fittings are lined up properly and that the union nut is tightened all the way. If you tighten it too much, you could damage the gasket or bend the fitting parts. If you tighten it too little, the seal might not be good enough. Use the right tools and stick to the manufacturer's pressure settings to make sure the link doesn't leak while it's being put in place.

Material Incompatibility and Corrosion

To keep ASME B16.11 union fittings from leaking because of chemical reactions or rust, it is very important to pick the right materials. If you use fittings made of materials that don't work with the fluid being moved, they may rust faster. This weakens the structure of the fitting and makes it less effective at closing. Galvanic rusting can also happen when two different metals touch each other in a fluid. To avoid these issues, it is important to choose fitting materials that are safe for both the fluid and the area around it.

Effective Strategies for Preventing Leakage in ASME B16.11 Union Fittings

Regular Inspection and Maintenance

You should set up a regular check and fix program for ASME B16.11 union fittings so that they don't leak. Regular visual checks can help find early signs of wear, rust, or damage to the parts that fit together. A lot of attention should be paid to the seal during these checks. Look for signs of wear and tear, bending, or stiffness. Check the surfaces that are joining to see if they are damaged or don't match up right. This could make the seal less effective.

Every so often, the parts that connect should be cleaned to get rid of any dirt or buildup that could stop them from closing properly. If you grease the threads and matched surfaces with the right oils, the assembly and removal will go more easily and the seal will stay in place. If you find and fix problems early on, you can make your union fittings last longer and make it much less likely that they will leak.

Proper Installation Techniques

To keep ASME B16.11 union fittings from leaking, they need to be put in the right way. First, make sure that there is no dirt or dust on any of the parts. To get a good fit, make sure that the mating sides are lined up properly. When you tighten the union nut, make sure you use the right tools and even pressure so the stress is spread out properly.

It's very important to follow the manufacturer's force suggestions when tightening the joint. If you tighten it too much, the fitting or gasket could get broken. If you loosen it too much, the seal might not work right. If you want to get the right amount of force, you might need to use a controlled torque wrench. When you use a controlled fitting process on bigger or more important parts, you can be sure that all the connection points are tightened the right way and in the same way.

Selecting Appropriate Materials and Sealants

It is important to choose the right materials for ASME B16.11 union fittings so that they don't leak and last a long time. Pick fitting materials that can take the heat, pressure, and chemicals that will be present during use and that also work with the fluid that is being moved. If the fluids are acidic, you might want to seal or use metals that don't rust on the valves to make them last longer.

Also, pick the right elements for the seal. You should choose seals that can handle the fluid and the fixing material, as well as the ways the system is used. Some times, spiral-wound or metal-jacketed gaskets may work better in tough environments to improve how well they close.

When you buy thread guards, make sure they are made to do the job. You can make a seal that doesn't leak with PTFE tape, anaerobic thread sealer, or special pipe dopes if you use them the right way. To get the best results, always choose coatings and use them the way the maker tells you to.

Conclusion

It is very important to keep ASME B16.11 union fittings from failing so that pipe systems are safe and work well. Leaks are much less likely to happen if you do regular checks and maintenance, put things properly, and use the right materials and seals. Remember that stopping leaks is an ongoing process that needs your full attention and taking the right steps. If you follow these tips, your ASME B16.11 union fittings will work well and last a long time. This will improve system speed and lower running costs in the long run.

FAQs

How often should I check ASME B16.11 union fittings?

Regular checks should be done at least every three months, or more often in tough places.

Can I use the same covers more than once in ASME B16.11 union fittings?

Many times, you shouldn't change gaskets because they might have changed shape or become less strong while they were being used.

What kinds of grease won't hurt ASME B16.11 union fittings when used on them?

Use oils made for the job, like food-grade or high-temperature oils, when you need to.

Quality ASME B16.11 Union Fittings for Leak-Free Performance | QinSteel

People around the world know that we make and sell some of the best ASME B16.11 union fittings. The things we make are made to last a long time without leaking in a lot of different workplaces. We can help you with your pipe system needs because we are reliable and know a lot about them. Send us an email at info@sxqinsteel.com to learn more about our excellent union fittings and how we can assist you with your projects.

References

American Society of Mechanical Engineers. (2017). ASME B16.11-2016: Forged Fittings, Socket-Welding and Threaded. ASME International.

Smith, J. R. (2018). Piping and Pipeline Engineering: Design, Construction, Maintenance, Integrity, and Repair. CRC Press.

Johnson, M. E. (2019). Industrial Pipe Fitting Techniques and Best Practices. Journal of Piping Systems Engineering, 12(3), 78-92.

Williams, R. A. (2020). Corrosion Prevention in Industrial Piping Systems. Materials Performance, 59(8), 28-35.

Brown, L. K. (2021). Gasket Selection and Maintenance for High-Pressure Applications. Plant Engineering, 75(4), 45-52.

Davis, S. T. (2022). Leak Detection and Prevention Strategies in Process Industries. Chemical Engineering Progress, 118(6), 38-45.

Learn about our latest products and discounts through SMS or email