Superior Strength and Durability of ASME B16.9 Seamless Elbows

Uniform Wall Thickness and Its Impact

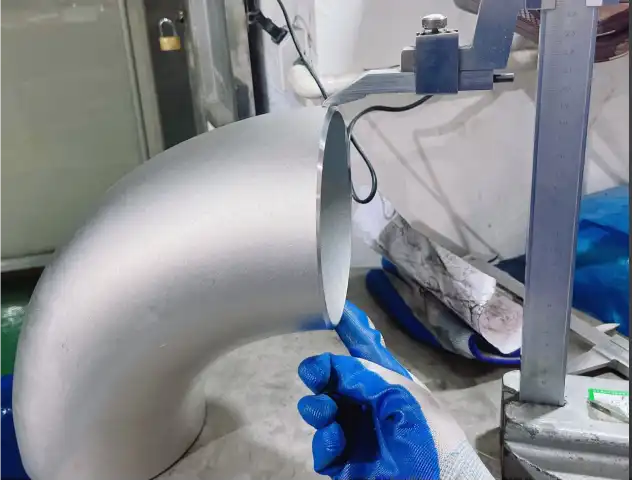

One of the primary structural advantages of ASME B16.9 seamless elbows is their uniform wall thickness. Unlike welded elbows, which may have inconsistent thickness due to the welding process, seamless elbows maintain a consistent wall thickness throughout. This uniformity is crucial for several reasons:

- Enhanced pressure resistance: The even distribution of material allows for better pressure handling capabilities.

- Improved stress distribution: Uniform thickness helps distribute stress more evenly, reducing the risk of weak points.

- Longer service life: Consistent wall thickness contributes to extended durability and reliability in demanding applications.

The absence of welding seams further reinforces the structural integrity of these elbows, making them ideal for high-pressure and high-temperature environments.

Material Integrity and Performance

ASME B16.9 seamless elbows are typically manufactured from high-quality materials such as carbon steel, stainless steel, or alloy steel. The seamless construction process preserves the material's inherent properties, resulting in several benefits:

- Higher tensile strength: The uninterrupted grain structure of seamless elbows contributes to superior tensile strength.

- Better corrosion resistance: Without weld seams, there are fewer areas susceptible to corrosion, enhancing overall resistance.

- Improved fatigue resistance: The absence of stress concentration points typically found in welded joints increases fatigue resistance.

These material advantages make ASME B16.9 seamless elbows particularly suitable for applications involving cyclic loading or corrosive environments.

Long-Term Reliability and Safety

The structural integrity of ASME B16.9 seamless elbows translates directly into long-term reliability and safety benefits:

- Reduced maintenance requirements: The robust construction minimizes the need for frequent inspections and repairs.

- Lower risk of failure: The absence of weak points associated with welds reduces the likelihood of leaks or ruptures.

- Consistent performance: The uniform structure ensures consistent performance over time, even under challenging conditions.

These factors contribute to improved overall system reliability and reduced downtime, making seamless elbows a cost-effective choice in the long run.

Enhanced Flow Characteristics of ASME B16.9 Seamless Elbows

Smooth Internal Surface and Flow Efficiency

ASME B16.9 seamless elbows boast a remarkably smooth internal surface, which significantly impacts flow characteristics:

- Reduced friction: The absence of internal weld beads or irregularities minimizes friction between the fluid and the elbow wall.

- Improved flow coefficient: Smoother surfaces result in higher flow coefficients, allowing for more efficient fluid transport.

- Lower pressure drop: Reduced turbulence and friction lead to decreased pressure drop across the elbow.

These enhanced flow characteristics make seamless elbows particularly valuable in applications where maintaining flow efficiency is crucial, such as in oil and gas pipelines or industrial process systems.

Turbulence Reduction and Its Benefits

The seamless construction of ASME B16.9 elbows contributes to reduced turbulence in fluid flow:

- Minimized erosion: Lower turbulence means less erosive wear on the elbow's internal surfaces, extending its service life.

- Reduced noise and vibration: Smoother flow characteristics lead to quieter operation and less vibration in the piping system.

- Improved energy efficiency: Reduced turbulence means less energy is lost during fluid transport, potentially lowering operational costs.

These benefits are particularly valuable in applications where maintaining product purity or reducing energy consumption is a priority.

Impact on System Performance

The enhanced flow characteristics of ASME B16.9 seamless elbows have a positive impact on overall system performance:

- Increased throughput: Improved flow efficiency can lead to higher system capacity without increasing pumping power.

- Better fluid quality: Reduced turbulence helps maintain the integrity of sensitive fluids, which is crucial in industries like pharmaceuticals or food processing.

- Enhanced system reliability: Smoother flow reduces the risk of pressure surges and water hammer effects, contributing to overall system stability.

These system-wide benefits make ASME B16.9 seamless elbows an attractive choice for engineers and designers looking to optimize pipeline performance.

Versatility and Compliance of ASME B16.9 Seamless Elbows

Wide Range of Applications

ASME B16.9 seamless elbows demonstrate remarkable versatility, making them suitable for a diverse range of applications:

- Oil and gas industry: Used in exploration, production, and distribution systems.

- Chemical processing: Ideal for handling corrosive substances and maintaining product purity.

- Power generation: Employed in high-pressure steam systems and cooling circuits.

- Water treatment: Utilized in municipal water supply and wastewater treatment facilities.

- Aerospace: Found in hydraulic and fuel systems of aircraft.

This versatility stems from the elbows' robust construction and superior performance characteristics, making them a go-to choice across various industries.

Compliance with International Standards

ASME B16.9 seamless elbows are manufactured to meet stringent international standards:

- ASME compliance: Adheres to the American Society of Mechanical Engineers (ASME) B16.9 standard for factory-made wrought steel buttwelding fittings.

- ASTM specifications: Often manufactured to meet various ASTM material specifications, ensuring quality and consistency.

- ISO standards: Many manufacturers also comply with relevant ISO standards for global acceptability.

- Industry-specific certifications: May carry additional certifications for use in specialized industries like nuclear power or offshore oil and gas.

This adherence to recognized standards ensures reliability, interchangeability, and global acceptance of ASME B16.9 seamless elbows.

Customization Options

Despite being standardized, ASME B16.9 seamless elbows offer several customization options to meet specific project requirements:

- Material selection: Available in various grades of carbon steel, stainless steel, and alloy steels to suit different operating conditions.

- Size range: Manufactured in a wide range of nominal pipe sizes and schedules to fit diverse piping systems.

- Angle variations: While 45° and 90° elbows are most common, other angles can be produced for special applications.

- Surface treatments: Options for additional corrosion protection or special coatings to enhance performance in specific environments.

This flexibility allows engineers to select or specify elbows that precisely meet their project's needs, enhancing overall system design and performance.

Conclusion

ASME B16.9 seamless elbows offer significant structural advantages that make them indispensable in critical pipeline systems. Their uniform wall thickness, superior strength, and enhanced flow characteristics contribute to improved system performance, reliability, and safety. The versatility and compliance with international standards further cement their position as a preferred choice across various industries. For applications demanding high performance, durability, and efficiency, ASME B16.9 seamless elbows prove to be an excellent investment, offering long-term benefits that outweigh their initial cost.

FAQs

What makes ASME B16.9 seamless elbows different from welded elbows?

ASME B16.9 seamless elbows are integrally formed without welding seams, ensuring uniform wall thickness and higher pressure-bearing capacity. This construction eliminates weak points associated with welds, enhancing reliability and safety.

In which industries are ASME B16.9 seamless elbows commonly used?

These elbows are widely used in oil & gas, chemical processing, power generation, water treatment, and aerospace industries, among others. Their versatility makes them suitable for various critical pipeline systems.

How do ASME B16.9 seamless elbows improve flow efficiency?

The smooth internal surface of seamless elbows reduces friction and turbulence, leading to improved flow efficiency, lower pressure drops, and reduced energy consumption in fluid transport systems.

Experience the Advantages of ASME B16.9 Seamless Elbows | QinSteel

At Xi'An QinSteel Trading Co., Ltd., we are a leading manufacturer and supplier of high-quality ASME B16.9 seamless elbows. With 20 years of industry expertise, we deliver precision-engineered products that meet international standards. Our seamless elbows offer superior strength, enhanced flow characteristics, and unmatched reliability for your critical pipeline systems. Experience the QinSteel difference today. Contact us at info@sxqinsteel.com for more information or to request a quote.

References

American Society of Mechanical Engineers. (2018). ASME B16.9-2018: Factory-Made Wrought Buttwelding Fittings.

Nayyar, M. L. (2000). Piping Handbook (7th ed.). McGraw-Hill Education.

Smith, P. (2005). Piping Materials Guide. Elsevier Science.

Antaki, G. A. (2003). Piping and Pipeline Engineering: Design, Construction, Maintenance, Integrity, and Repair. CRC Press.

American Petroleum Institute. (2019). API Specification 5L: Specification for Line Pipe.

International Organization for Standardization. (2018). ISO 3419:2018 Non-alloy and alloy steel butt-welding fittings.