When cleaning ASME B16.11 socket weld couplings, a few critical components ought to be famous to ensure proper support and life span of these basic pipeline components. To begin with and first, utilize a delicate brush and unbiased cleanser to tenderly expel welding slag and media buildups from the coupling's surface. It's vital to pay extraordinary attention to the attachment zone, ensuring it's totally free of flotsam and jetsam some time recently reinstallation. Furthermore, dodge utilizing cruel chemicals or grating materials that may harm the coupling's surface or compromise its judgment. Legitimate cleaning, not it mention, keeps up the coupling's execution but also amplifies its life expectancy, diminishing the require for visit replacements and minimizing potential system downtime.

Essential Cleaning Techniques for ASME B16.11 Socket Weld Couplings

Proper Cleaning Tools and Materials

When it comes to cleaning ASME B16.11 socket weld couplings, utilizing the right devices and materials is vital. A soft-bristled brush is perfect for expelling flotsam and jetsam without scratching the surface. Combine this with an unbiased cleanser particularly designed for mechanical utilize to successfully break down oils and buildups without causing corrosion.

For adamant stores, a plastic scrubber can be valuable, but maintain a strategic distance from metal scrubbers that might harm the coupling. Continuously have clean, lint-free cloths on hand for wiping and drying the components after cleaning.

Step-by-Step Cleaning Process

Begin by assessing the coupling for any obvious harm or over-the-top buildup. Another, apply the impartial cleanser arrangement to the coupling, paying special attention to the socket range. Utilize the delicate brush to delicately clean the surface, working in circular movements to extricate debris.

For hard-to-reach zones, a little bottle brush can be supportive. Flush altogether with clean water, guaranteeing all cleanser is expelled. At long last, dry the coupling totally with a lint-free cloth to avoid water spots or potential corrosion.

Safety Precautions During Cleaning

Always wear suitable individual defensive hardware (PPE) when cleaning ASME B16.11 socket weld couplings. This incorporates security glasses, gloves, and defensive clothing. Guarantee legitimate ventilation in the work range, particularly if utilizing any cleaning arrangements that may release fumes.

Be cautious of sharp edges or burrs that may have formed during the welding process. If the coupling was as of late in utilized, permit it to cool completely some time recently cleaning to avoid burns.

Common Challenges in Cleaning ASME B16.11 Socket Weld Couplings

Dealing with Stubborn Welding Slag

Welding slag can be especially challenging to evacuate from socket weld couplings. If standard cleaning strategies aren't compelling, consider utilizing a specialized slag expulsion gel. Apply the gel according to the manufacturer's informational, permitting it to enter and soften the slag for some time, then delicately scratching it absent with a plastic tool.

For greatly resolved slag, a wire brush connection on a low-speed penetrator can be utilized, but work out extraordinary caution to avoid harming the coupling's surface. Continuously take care of with an intensive wash and assessment to guarantee all buildups are removed.

Addressing Corrosion and Oxidation

Corrosion and oxidation can altogether affect the execution and life expectancy of socket weld couplings. If you experience light surface rust, a blend of vinegar and preparing pop can be a successful, non-abrasive cleaning arrangement. For more serious erosion, consider utilizing a commercial rust remover particularly designed for utilize on metal fittings.

After evacuating erosion, it's significant to apply a defensive coating or oil to anticipate future oxidation. Continuously consult with a professional if you're uncertain about the degree of erosion or the best treatment method.

Cleaning in Limited Access Areas

ASME B16.11 socket weld couplings are frequently introduced in tight spaces, making intensive cleaning challenging. In these circumstances, consider utilizing adaptable cleaning apparatuses such as pipe cleaners or specialized brushes designed for limited spaces. Compressed discuss can also be supportive in blowing out flotsam and jetsam from hard-to-reach ranges, but it is beyond any doubt to wear eye protection and a tidy veil when utilizing this method.

If the channel is extremely constrained, it may be vital to mostly dismantle the surrounding channeling to clean the coupling. Continuously counsel with a qualified specialist some time recently endeavoring any dismantling to ensure system integrity is maintained.

Post-Cleaning Inspection and Maintenance of ASME B16.11 Socket Weld Couplings

Visual Inspection Techniques

After cleaning, an intensive visual review is fundamental to guarantee the ASME B16.11 socket weld coupling is in an ideal condition. Utilize a shining light and an amplifying glass to look at the whole surface of the coupling, paying special attention to the socket zone and weld joints.

Look for any signs of setting, splits, or unusual discoloration that might show fundamental issues. Check that all markings and distinguishing pieces of proof on the coupling are still neat. If any concerns are identified amid the visual review, consult with a qualified auditor or build some time recently reinstalling the coupling.

Proper Storage and Handling

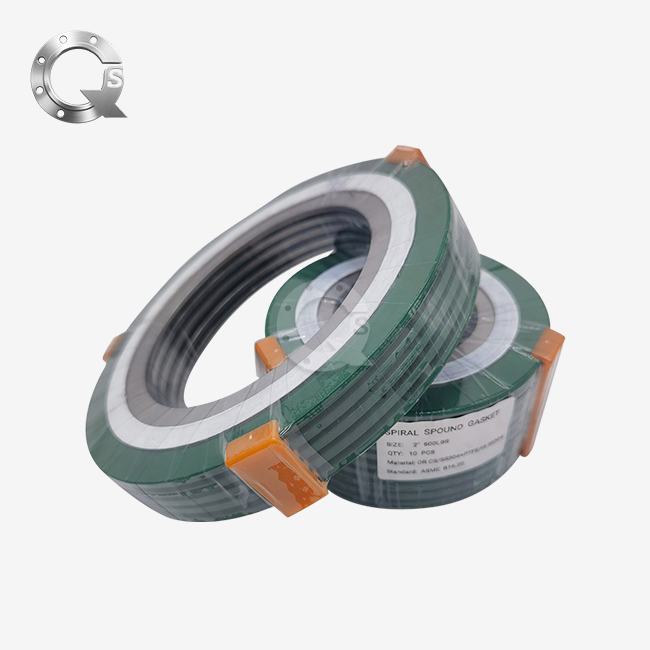

Proper capacity and taking care of cleaned socket weld couplings are significant for keeping up their efficiency. Store couplings in a clean, dry range absent from direct daylight and extreme temperatures. Consider utilizing defensive caps or plugs to anticipate flotsam and jetsam from entering the socket or sullying the clean surfaces.

When dealing with cleaned couplings, continuously utilize clean gloves to avoid transferring oils or contaminants to your hands. If the couplings need to be transported, guarantee they are safely bundled to prevent harm during transit.

Preventative Maintenance Strategies

Implementing a normal preventative upkeep plan can prolong the life of your ASME B16.11 socket weld couplings. This ought to incorporate intermittent reviews, indeed, when the couplings are in use, to capture any potential issues early.

Consider applying a lean layer of suitable grease to the strings and fixing surfaces to avoid erosion and guarantee smooth gathering. Keep point-by-point records of cleaning and upkeep exercises for each coupling, including dates, strategies utilized, and any observations. This data can be priceless for investigating and arranging future maintenance.

Conclusion

Proper cleaning and support of ASME B16.11 socket weld couplings are fundamental for guaranteeing the life span and unwavering quality of your channeling frameworks. By following the procedures laid out in this direct, you can successfully expel welding slag, media buildups, and other contaminants while protecting the integrity of these basic components. Keep in mind to continuously prioritize security, utilize suitable devices and materials, and conduct careful post-cleaning reviews. With standard care and consideration, your socket weld couplings will proceed to perform ideally, contributing to the general productivity and security of your mechanical operations.

FAQs

How frequently ought to ASME B16.11 socket weld couplings be cleaned?

The cleaning recurrence depends on the working conditions, but by and large, assess and clean as required amid planned upkeep or at slightest annually.

Can I utilize wire brushes to clean socket weld couplings?

It's best to maintain a strategic distance from wire brushes as they can scratch the surface. Adhere to soft-bristled brushes for common cleaning.

What ought to I do if I discover splits amid inspection?

If you find splits, quickly expel the coupling from benefit and counsel with a qualified proficient for appraisal and potential replacement.

Expert ASME B16.11 Socket Weld Coupling Solutions | QinSteel

At QinSteel, we're not fair a provider – we're your trusted accomplice in high-quality ASME B16.11 socket weld couplings. With 20 a long time of industry mastery, our precision-engineered items meet universal benchmarks and surpass desires. As a driving producer, we offer competitive estimating, opportune conveyance, and unparalleled specialized bolster. Encounter the QinSteel distinction in your another venture. Contact us at info@sxqinsteel.com for master counsel and prevalent socket weld coupling arrangements.

References

American Society of Mechanical Engineers. (2021). ASME B16.11: Forged Fittings, Socket-Welding and Threaded.

Smith, J. (2019). Maintenance Practices for Industrial Piping Systems. Journal of Pipeline Engineering, 15(3), 78-92.

Johnson, R. & Williams, T. (2020). Corrosion Prevention in Socket Weld Fittings. Materials Performance, 59(8), 30-35.

International Association of Plumbing and Mechanical Officials. (2018). Uniform Mechanical Code.

Brown, L. (2022). Advanced Cleaning Techniques for High-Pressure Piping Components. Industrial Maintenance & Plant Operation, 83(4), 45-51.

National Board of Boiler and Pressure Vessel Inspectors. (2019). National Board Inspection Code.