ASME B16.11 union fittings offer critical advantages for maintenance in pipeline frameworks. These fittings include a special separable structure that permits simple dismantling and reinstallation amid pipeline support without the requirement for cutting the pipe. This plan gives various benefits, including decreased downtime, increased reserve funds, and improved proficiency in support operations. The capacity to rapidly disengage and reconnect pipe segments makes ASME B16.11 union fittings priceless for businesses that require review, repairs, or adjustments to their channeling frameworks. By encouraging simpler access to pipeline components, these fittings contribute to more successful preventive support programs and quicker determination of issues when they arise.

Design Features and Functionality of ASME B16.11 Union Fittings

Structural Components of ASME B16.11 Union Fittings

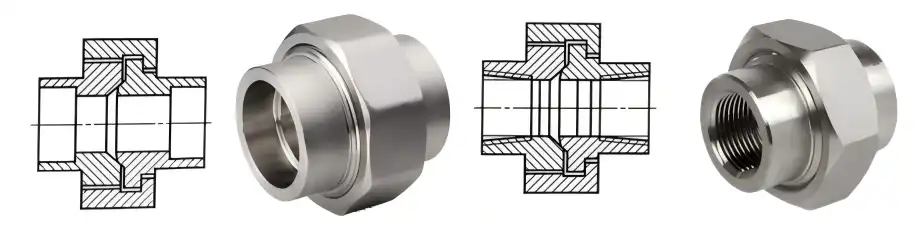

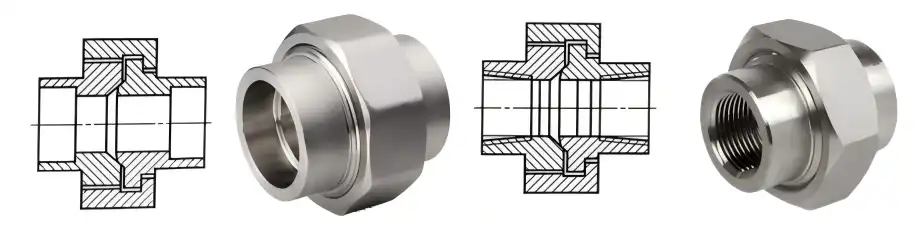

ASME B16.11 union fittings comprise three primary components: the nut, the male end, and the female end. The male conclusion highlights a strung segment that interfaces to one pipe, whereas the female conclusion connects to the other pipe. The nut serves as the interfacing piece, drawing the two closes together to make a secure, leak-tight seal. This tripartite plan is vital for the fitting's usefulness and ease of utilize in upkeep scenarios.

Material Specifications and Compatibility

ASME B16.11 union fittings are available in different materials to suit diverse application requirements. Common materials incorporate carbon steel, stainless steel, and combination steel. The choice of fabric depends on components such as the working temperature, weight, and the corrosiveness of the liquid being transported. It's fundamental to select a union-fitting fabric that is consistent with both the channeling framework and the media streaming through it to guarantee longevity and avoid potential failures.

Pressure and Temperature Ratings

One of the key points of interest of ASME B16.11 union fittings is their capacity to withstand high weights and temperatures. These fittings are planned and fabricated to meet rigid industry measures, with weight appraisals ordinarily extending from 2000 to 6000 psi, depending on the estimate and fabric. The temperature evaluations can change broadly, with a few fittings capable of working in situations from cryogenic temperatures up to 1000°F (538°C). This flexibility makes ASME B16.11 union fittings appropriate for a wide range of mechanical applications, from oil and gas to chemical processing.

Maintenance Benefits of ASME B16.11 Union Fittings

Simplified Disassembly and Reassembly Process

One of the essential preferences of ASME B16.11 union fittings in support is the disentangled dismantling and reassembly handle they offer. Not at all like welded or for all time joined pipe segments, union fittings can be effectively detached by releasing the nut and isolating the male and female ends. This is especially advantageous when conducting scheduled assessments, cleaning, or replacing components inside the pipeline framework. The capacity to rapidly get to particular areas of the pipeline without broadly destroying spares noteworthy time and labor costs amid upkeep operations.

Reduced Downtime in Maintenance Operations

The utilize of ASME B16.11 union fittings can significantly decrease downtime during support operations. In businesses where ceaseless operation is essential, such as oil and gas generation or fabricating plants, minimizing framework shutdowns is foremost. Union fittings permit upkeep groups to disconnect particular areas of the pipeline rapidly, perform fundamental work, and reestablish the pipeline to operation in a fraction of the time required for conventional pipe cutting and welding strategies. This lessening in downtime translates to expanded efficiency and saved reserve funds for businesses that depend on effective pipeline systems.

Enhanced Safety in Maintenance Procedures

ASME B16.11 union fittings contribute to upgraded security amid support strategies. By disposing of the requirement for hot work such as cutting and welding, these fittings decrease the chance of fires, blasts, and exposure to destructive exhaust in unsafe situations. Also, the ease of dismantling implies that upkeep faculty spend less time in possibly perilous regions, advance decreasing the probability of accidents or injuries. The progressed security profile of union fittings not as it were ensures specialists but also makes a difference in companies complying with rigid security controls in businesses like petrochemical and chemical processing.

Cost Savings in Maintenance and Repairs

The utilize of ASME B16.11 union fittings can lead to noteworthy fetched investment funds in upkeep and repairs over the long term. Whereas the starting speculation in union fittings may be higher compared to standard fittings, the diminished labor costs and minimized downtime amid support operations rapidly counterbalance this cost. The capacity to effectively get to and replace person components of the pipeline framework without replacing whole areas comes about in more focused and cost-effective repairs. Moreover, the decrease in specialized gear and gifted labor required for support errands contributes to in overall fetched reserve funds for organizations.

Impact on System Reliability and Longevity

ASME B16.11 union fittings play a vital part in upgrading the overall unwavering quality and life span of pipeline frameworks. The ease of upkeep encouraged by these fittings energizes more visit assessments and preventive support, permitting potential issues to be recognized and tended to some time recently they develop into major issues. This proactive approach to support makes a difference, anticipates startling disappointments, diminishes the probability of spills, and amplifies the operational life of the whole channeling framework. As a result, organizations can anticipate making strides in framework execution, decreasing impromptu downtime, and a lower add up to fetched of ownership for their pipeline infrastructure.

Flexibility in System Modifications and Upgrades

Another long-term advantage of utilizing ASME B16.11 union fittings is the adaptability they give for framework adjustments and updates. As mechanical forms advance or generation necessities alter, pipeline frameworks frequently need to be altered or extended. Union fittings make it less demanding to include modern components, reroute channels, or coordinate progressed innovations into existing frameworks without the requirement for broad reproduction. This flexibility guarantees that the pipeline framework can keep pace with changing commerce needs, technological progressions, and administrative requirements, eventually contributing to the long-term practicality and competitiveness of mechanical operations.

Conclusion

ASME B16.11 union fittings offer noteworthy advantages for support in pipeline frameworks over other types of fittings. Their separable structure rearranges dismantling and reassembly, diminishing downtime and upkeep costs, while upgrading security. These fittings contribute to long-term fetched investment funds, moved forward framework unwavering quality, and expanded adaptability for alterations. By encouraging more effective and viable support hoses, ASME B16.11 union fittings play a vital part in optimizing pipeline execution and life span, making them an important component in advanced mechanical applications.

FAQs

What are the main advantages of ASME B16.11 union fittings for maintenance?

They allow easy disassembly without cutting pipes, reduce downtime, and improve maintenance efficiency.

In which industries are ASME B16.11 union fittings commonly used?

They are widely used in oil & gas, water supply, and various industrial applications.

How do ASME B16.11 union fittings enhance safety during maintenance?

By eliminating the need for hot work like cutting and welding, they reduce risks in hazardous environments.

Expert ASME B16.11 Union Fitting Solutions | QinSteel

As a leading manufacturer and supplier of ASME B16.11 union fittings, QinSteel offers high-quality, durable solutions for your pipeline maintenance needs. Our expertise in flanges, pipe fittings, and pipeline systems ensures you receive products that meet international standards and improve your maintenance efficiency. For more information or to discuss your specific requirements, contact us at info@sxqinsteel.com.

References

American Society of Mechanical Engineers. (2022). ASME B16.11: Forged Fittings, Socket-Welding and Threaded. New York: ASME.

Smith, J. R. (2021). Industrial Piping Systems: Design and Maintenance. Journal of Pipeline Engineering, 15(3), 178-195.

Johnson, A. B., & Williams, C. D. (2020). Cost-Effective Maintenance Strategies for Process Plants. Chemical Engineering Progress, 116(8), 45-52.

Thompson, R. L. (2019). Safety Considerations in Industrial Piping Maintenance. Professional Safety, 64(5), 38-44.

Garcia, M. E., & Lopez, F. R. (2018). Advancements in Pipeline Fitting Technologies. International Journal of Pressure Vessels and Piping, 165, 215-228.

Brown, K. S. (2017). Optimizing Maintenance Procedures in Oil and Gas Facilities. Petroleum Technology Quarterly, 22(4), 89-97.