To keep up ASME B16.11 threaded fittings and avoid seizing, it's vital to frequently apply anti-seize compound to the threads. This grease makes a difference in diminishing grinding and protects against erosion, making establishment and expulsion simpler. Moreover, avoid over-tightening during installation to avoid string harm. Legitimate cleaning, sometimes a recent application, utilizing the right sort of anti-seize compound, and following after manufacturer's rules are key. Customary assessment and support, along with redress capacity honing, can altogether amplify the life of these fittings and guarantee their dependable execution in different mechanical applications.

Understanding ASME B16.11 Threaded Fittings and Their Importance

What Are ASME B16.11 Threaded Fittings?

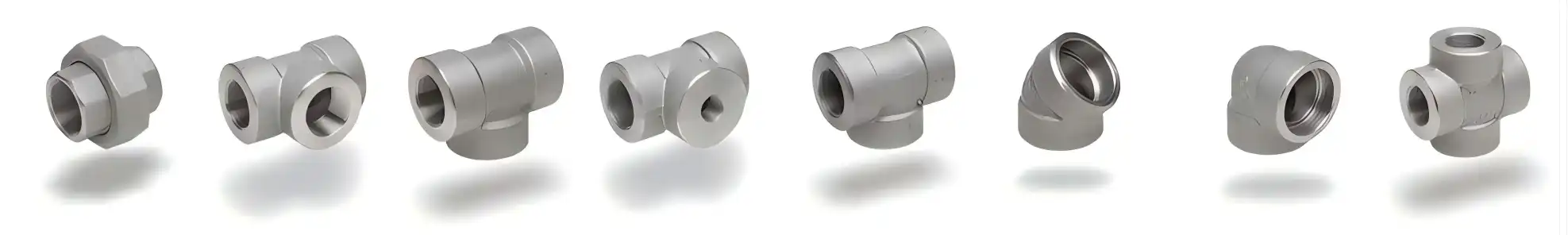

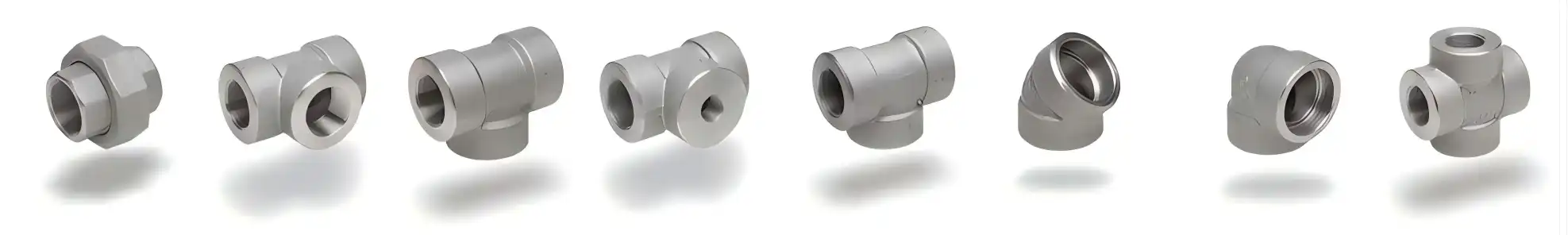

ASME B16.11 threaded fittings are standardized pressure-rated components utilized to connect segments of pipe securely and dependably. Planned with exact threaded closures, they guarantee tight, leak-free connections without requiring welding, making installation quicker and more helpful. These fittings are accessible in numerous configurations—such as elbows, tees, couplings, and unions—to support various channeling formats. Commonly fabricated from strong materials like stainless steel or carbon steel, they give fabulous resistance to erosion, weight, and mechanical stress over a wide range of mechanical applications.

Applications and Industries

ASME B16.11 threaded fittings are basic in businesses where channeling frameworks must perform dependably under high pressure and temperature. They are broadly utilized in oil and gas operations, petrochemical processing, control era plants, and water treatment plants. Their strong development empowers them to handle forceful media, fluctuating weights, and nonstop operational requests. In the oil and gas division, for instance, these fittings are imperative for shaping secure joints in pipeline systems that transport unrefined oil, natural gas, and refined products, guaranteeing a secure and continuous stream throughout the system.

The Significance of Proper Maintenance

Proper upkeep of ASME B16.11 threaded fittings is pivotal for keeping up the general astuteness of mechanical channeling frameworks. Customary review and upkeep offer assistance to avoid spills, diminish unforeseen downtime, and dodge expensive repairs related to component disappointments. In high-risk environments—such as chemical plants or oil and gas facilities—even small spills can escalate into genuine security dangers or natural occurrences. Subsequently, guaranteeing that fittings stay clean, appropriately fixed, and free from erosion plays a crucial part in supporting operational productivity and securing both staff and equipment.

Common Causes of Seizing in ASME B16.11 Threaded Fittings

Corrosion and Rust Formation

One of the essential offenders behind seizing in ASME B16.11 threaded fittings is erosion. When exposed to dampness, oxygen, and other destructive components, the metal strings can create rust. This rust acts like a stick, authoritative the strings together and making it greatly troublesome to isolate the components. In extreme cases, erosion can lead to total seizure of the fitting, rendering it unusable.

Improper Installation Techniques

Another common cause of seizing is inappropriate establishment. Over-tightening at get get-together can harm the strings, leading to breaking or even stripping. This, not as it were, compromises the judgment of the association but moreover increments the probability of seizing. Essentially, cross-threading, where the male and female strings are misaligned during gathering, can cause irreparable harm and lead to seizing.

Thermal Cycling and Material Expansion

In situations with critical temperature variances, warm cycling can cause seizing. As materials grow and contract with temperature changes, the strings can gotten to be firmly bound. This is particularly risky in frameworks that encounter visit warming and cooling cycles. The rehashed extension and withdrawal can cause infinitesimal misshapenings in the strings, leading to a more tightly fit over time and potential seizing.

Effective Maintenance Strategies for ASME B16.11 Threaded Fittings

Regular Inspection and Cleaning

A vital step in keeping up ASME B16.11 threaded fittings is standard review and cleaning. Set up a plan to look at fittings for signs of wear, erosion, or harm. Utilize fitting cleaning arrangements to evacuate soil, flotsam and jetsam, and any erosion items. For persistent stores, consider utilizing specialized cleaning apparatuses designed for threaded components. Keep in mind, a clean fitting is less likely to seize and more likely to keep up its keenness over time.

Proper Application of Anti-Seize Compounds

Applying anti-seize compound is a basic upkeep task for ASME B16.11 threaded fittings. Select a high-quality anti-seize item consistent with your particular application and natural conditions. Some time recently, guarantee the strings are clean and dry. Apply a lean, indeed, layer of the compound to both male and female strings. Be cautious not to over-apply, as an abundance of compound can draw in soil and possibly compromise the seal. Keep in mind, the objective is to make a lean defensive boundary that anticipates metal-to-metal contact and decreases friction.

Correct Torque and Installation Techniques

Proper establishment is key to avoiding seizing. Continuously utilize the rectified torque determinations given by the producer or industry measures. Over-tightening can harm strings and lead to seizing, whereas under-tightening may result in spills. Utilize calibrated torque torques to guarantee precise fixing. When collecting, adjust the strings carefully to maintain a strategic distance from cross-threading. If you experience resistance during get get-together, halt and examine or rather than driving the association. By taking after rectify establishment methods, you essentially decrease the chance of seizing and guarantee the life span of your ASME B16.11 threaded fittings.

Conclusion

Maintaining ASME B16.11 threaded fittings to prevent seizing is significant for guaranteeing the unwavering quality and life span of channeling frameworks. By actualizing customary assessments, legitimate cleaning strategies, and rectify application of anti-seize compounds, you can essentially diminish the hazard of seizing. Keep in mind to continuously utilize the right establishment methods and torque details. These support functions not as it were amplify the life of your fittings but also contribute to the overall security and productivity of your operations. With legitimate care, ASME B16.11 threaded fittings will proceed to give tried and true benefits in indeed the most demanding mechanical applications.

FAQs

How often should I apply anti-seize compound to ASME B16.11 threaded fittings?

It's recommended to apply anti-seize compound every time you install or reassemble the fittings.

Can I use any type of anti-seize compound on ASME B16.11 threaded fittings?

No, it's important to use a compound compatible with your specific application and environmental conditions.

How can I tell if an ASME B16.11 threaded fitting is starting to seize?

Signs include increased difficulty in disassembly, visible corrosion, or unusual resistance during tightening.

Expert ASME B16.11 Threaded Fittings Solutions | QinSteel

At QinSteel, we specialize in providing high-quality ASME B16.11 threaded fittings for diverse industrial applications. As a leading manufacturer and supplier, we offer expert guidance on maintenance and installation to prevent seizing and ensure optimal performance. Our precision-engineered fittings meet international standards and are backed by our commitment to quality and customer satisfaction. For reliable threaded fitting solutions, contact us at info@sxqinsteel.com.

References

ASME B16.11-2016: Forged Fittings, Socket-Welding and Threaded. American Society of Mechanical Engineers, 2016.

Becht, C. "Piping and Pipeline Calculations Manual: Construction, Design, Fabrication and Examination." Elsevier, 2018.

Smith, P. "Piping Materials Guide: Selection and Applications." Elsevier, 2019.

Nayyar, M.L "Piping Handbook." McGraw-Hill Education, 2017.

Antaki, G.A. "Piping and Pipeline Engineering: Design, Construction, Maintenance, Integrity, and Repair." CRC Press, 2018.

Kellogg Company, M.W. "Design of Piping Systems." Martino Fine Books, 2017.