- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Makes High-Pressure Flanges Suitable for Extreme Pressure Environments?

Nov 25 2025

High-pressure flanges are engineered to withstand extreme pressure environments, making them indispensable in various industrial applications. These robust components are designed with thickened bodies and dense forged structures, enabling them to handle pressures exceeding 10MPa without deformation or leakage. Their exceptional strength, durability, and precision engineering make high-pressure flanges the ideal choice for critical systems in oil and gas, chemical processing, and power generation industries. By distributing pressure evenly and maintaining a tight seal, these flanges ensure safety and reliability in the most demanding operational conditions, effectively preventing catastrophic failures and costly downtimes.

Key Design Features of High-Pressure Flanges

Material Selection and Composition

The choice of materials plays a crucial role in the performance of high-pressure flanges. Manufacturers typically use high-strength alloys such as stainless steel, carbon steel, or nickel alloys. These materials offer excellent resistance to corrosion, temperature extremes, and mechanical stress. The composition of these alloys is carefully engineered to enhance their strength-to-weight ratio, ensuring optimal performance under high-pressure conditions.

For instance, austenitic stainless steel grades like 316 or 304 are popular choices due to their superior corrosion resistance and mechanical properties. In more aggressive environments, super duplex stainless steel or nickel-based alloys like Inconel may be employed. These materials provide exceptional resistance to both high pressures and corrosive media, making them ideal for use in offshore oil and gas applications or chemical processing plants.

Structural Reinforcement Techniques

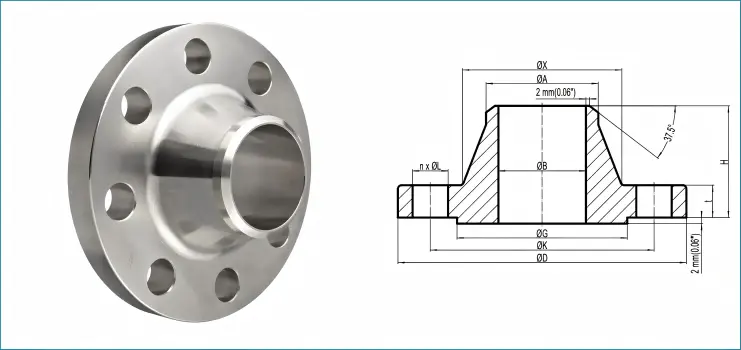

High-pressure flanges incorporate various structural reinforcement techniques to enhance their pressure-bearing capacity. One common approach is the use of thicker flange bodies, which increases the overall strength and rigidity of the component. Engineers carefully calculate the required thickness based on factors such as operating pressure, temperature, and flange size.

Another effective reinforcement method is the implementation of hub designs. Hubs are thickened sections at the bore of the flange that provide additional support and help distribute stress more evenly. This design feature is particularly important in preventing localized deformation and maintaining the integrity of the flange-pipe connection under extreme pressures.

Precision Manufacturing Processes

The manufacturing process of high-pressure flanges is critical to their performance in extreme environments. Advanced forging techniques are employed to create a dense, uniform grain structure within the metal, enhancing its strength and resistance to fatigue. This process involves carefully controlled heating and shaping of the metal, resulting in a flange with superior mechanical properties compared to cast or machined alternatives.

Precision machining is then used to achieve the required dimensional accuracy and surface finish. Computer Numerical Control (CNC) machining ensures that critical features such as sealing surfaces, bolt holes, and raised faces meet stringent tolerances. This level of precision is essential for creating a reliable seal and maintaining proper alignment under high-pressure conditions.

Performance Characteristics in Extreme Environments

Pressure Resistance and Leak Prevention

The primary function of high-pressure flanges is to maintain a secure connection and prevent leaks under extreme pressures. This is achieved through a combination of robust design and precise engineering. The thickened body and reinforced structure of these flanges allow them to withstand internal pressures that would cause standard flanges to fail or deform.

To enhance leak prevention, high-pressure flanges often incorporate specialized sealing mechanisms. These may include metal-to-metal seals, which become more effective as pressure increases, or advanced gasket designs that can maintain their integrity under high compressive loads. The careful selection of sealing materials and configurations is crucial for ensuring zero-leak performance in critical applications.

Temperature Resistance and Thermal Cycling

Many extreme pressure environments also involve high temperatures or significant temperature fluctuations. High-pressure flanges are designed to maintain their structural integrity and sealing capabilities across a wide temperature range. This is particularly important in industries such as oil refining or power generation, where operating temperatures can vary dramatically.

Materials used in high-pressure flanges are selected for their ability to resist thermal expansion and contraction without compromising the seal. Additionally, the design of these flanges often incorporates features that accommodate thermal cycling, such as flexible sealing elements or controlled bolt loading techniques. These measures help prevent leaks and maintain joint integrity even when subjected to repeated heating and cooling cycles.

Corrosion and Chemical Resistance

In many industrial applications, high-pressure flanges are exposed to corrosive chemicals or harsh environmental conditions. To ensure long-term reliability, these flanges are often manufactured from corrosion-resistant alloys or treated with protective coatings. The choice of material depends on the specific chemical environment and operating conditions of the application.

For instance, flanges used in offshore oil and gas platforms may be made from duplex stainless steel to resist chloride-induced stress corrosion cracking. In chemical processing plants, high-pressure flanges might be constructed from exotic alloys like Hastelloy or titanium to withstand aggressive acids or caustic solutions. This emphasis on material selection and surface treatment ensures that high-pressure flanges maintain their integrity even in the most challenging chemical environments.

Applications and Industry Standards

Oil and Gas Industry Applications

The oil and gas industry heavily relies on high-pressure flanges for various critical applications. In upstream operations, these flanges are used in wellhead equipment, where they must withstand extreme pressures and temperatures encountered during drilling and production. Subsea applications present additional challenges, requiring flanges that can operate reliably at great depths and resist corrosion from seawater.

In midstream and downstream sectors, high-pressure flanges are essential components in pipelines, refineries, and processing plants. They play a crucial role in maintaining the integrity of high-pressure piping systems that transport crude oil, natural gas, and refined products. The ability of these flanges to provide leak-tight connections under varying pressure and temperature conditions is vital for operational safety and efficiency.

Chemical and Petrochemical Processing

Chemical and petrochemical industries utilize high-pressure flanges in a wide range of processing equipment and piping systems. These environments often involve corrosive chemicals, high temperatures, and extreme pressures, making the selection of appropriate flange materials and designs critical. High-pressure flanges in these applications must not only withstand the operational conditions but also ensure the containment of hazardous substances.

Common applications include reactor vessels, high-pressure heat exchangers, and process piping for the production of chemicals such as ammonia, ethylene, and polymers. The ability of high-pressure flanges to maintain their integrity in these demanding environments is essential for preventing chemical leaks, ensuring worker safety, and protecting the environment.

Compliance with International Standards

The design, manufacturing, and testing of high-pressure flanges are governed by stringent international standards to ensure safety and reliability. Organizations such as the American Society of Mechanical Engineers (ASME) and the American Petroleum Institute (API) provide comprehensive guidelines for flange specifications, materials, and testing procedures.

For instance, ASME B16.5 and ASME B16.47 are widely recognized standards that cover pressure-temperature ratings, dimensions, and tolerances for various flange types. These standards ensure that high-pressure flanges meet the required performance criteria and can be safely integrated into piping systems across different industries and regions. Compliance with these standards is often mandatory for projects in the oil and gas, chemical, and power generation sectors, providing assurance of quality and reliability in extreme pressure environments.

Conclusion

High-pressure flanges are essential components in extreme pressure environments, offering unparalleled strength, durability, and reliability. Their advanced design features, including thickened bodies and dense forged structures, enable them to withstand pressures exceeding 10MPa without compromising integrity. From material selection to precision manufacturing processes, every aspect of high-pressure flanges is engineered to ensure optimal performance in the most demanding industrial applications. By providing secure connections and preventing leaks under extreme conditions, these flanges play a critical role in maintaining safety and operational efficiency across various sectors, including oil and gas, chemical processing, and power generation.

FAQs

What is the maximum pressure rating for high-pressure flanges?

High-pressure flanges can withstand pressures above 10MPa, with some designs capable of handling even higher pressures depending on their specific construction and materials.

How do high-pressure flanges prevent leaks?

They use thickened bodies, dense forged structures, and specialized sealing mechanisms to distribute pressure evenly and maintain a tight seal under extreme conditions.

Are high-pressure flanges suitable for corrosive environments?

Yes, when manufactured from corrosion-resistant materials like stainless steel or specialized alloys, they can withstand harsh chemical environments.

Expert High-Pressure Flange Solutions for Extreme Environments | QinSteel

As a leading manufacturer and exporter of high-pressure flanges, Xi'an QinSteel Trading Co., Ltd. offers superior quality products engineered to excel in extreme pressure environments. Our comprehensive range of flanges, pipe fittings, and pipeline systems meets international standards and caters to diverse industrial needs. With 20 years of expertise, we deliver reliable, precision-engineered solutions globally. For inquiries about our high-pressure flange products, contact us at info@sxqinsteel.com.

References

ASME B16.5-2017: Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard

API 6A: Specification for Wellhead and Christmas Tree Equipment

Flange Design for High Pressure Applications in the Oil and Gas Industry, Journal of Pressure Vessel Technology, 2019

Materials Selection for High Pressure Flanges in Corrosive Environments, Corrosion Science, 2020

Advanced Manufacturing Techniques for High-Pressure Flanges, International Journal of Advanced Manufacturing Technology, 2021

Performance Analysis of High-Pressure Flanges in Extreme Temperature Conditions, Energy Procedia, 2022

Learn about our latest products and discounts through SMS or email