Material Selection: The Foundation of High-Temperature Performance

Alloy Steel: The Preferred Choice for Extreme Temperatures

When it comes to high-temperature applications, alloy steel stands out as the material of choice for forged flanges. These specialized steel grades are engineered to maintain their strength and integrity even under extreme heat conditions. Alloy steels typically contain elements such as chromium, molybdenum, and nickel, which enhance their high-temperature properties.

For instance, grades like F11, F22, and F91 are commonly used in high-temperature forged flanges due to their excellent creep resistance and thermal stability. These materials can withstand temperatures well above 400℃ without significant degradation in mechanical properties, making them ideal for applications in power plants, refineries, and chemical processing facilities.

Thermal Stability: Ensuring Consistent Performance

Thermal stability is a critical factor in the selection of high-temperature forged flanges. Materials that exhibit good thermal stability maintain their dimensional integrity and mechanical properties even when subjected to prolonged exposure to high temperatures. This characteristic is essential for preventing leaks, maintaining proper sealing, and ensuring the overall reliability of the piping system.

Engineers must consider the coefficient of thermal expansion (CTE) when selecting flange materials. Materials with lower CTEs are generally preferred for high-temperature applications as they experience less dimensional change with temperature fluctuations, reducing the risk of thermal stress and fatigue.

Corrosion Resistance: Combating Harsh Environments

In many high-temperature applications, corrosion resistance is just as important as thermal stability. The combination of high temperatures and potentially corrosive media can rapidly degrade standard materials. Therefore, selecting high-temperature forged flanges with adequate corrosion resistance is crucial for ensuring long-term performance and safety.

Alloy steels with higher chromium content, such as stainless steel grades 304H and 316H, offer excellent corrosion resistance in addition to their high-temperature capabilities. For extremely corrosive environments, special alloys like Inconel or Hastelloy may be necessary, although these come at a higher cost.

Operating Conditions: Matching Flanges to Application Requirements

Temperature Range: Beyond the 400℃ Threshold

The specific operating temperature range is perhaps the most critical factor in selecting high-temperature forged flanges. While 400℃ is often considered the lower threshold for high-temperature applications, many industrial processes operate at much higher temperatures. For example, some petrochemical processes can reach temperatures of 800℃ or more.

It's essential to choose a flange material that not only withstands the maximum operating temperature but also maintains its properties throughout the entire temperature range it will experience, including during start-up, shutdown, and potential upset conditions. This requires a thorough understanding of the material's behavior at various temperatures and careful consideration of safety factors.

Pressure Ratings: Balancing Strength and Temperature

Pressure ratings are another crucial factor in the selection of high-temperature forged flanges. As temperature increases, the allowable working pressure of a flange typically decreases. This inverse relationship between temperature and pressure capacity must be carefully considered to ensure the chosen flange can safely contain the system pressure at the maximum operating temperature.

Engineers should refer to pressure-temperature ratings provided by manufacturers or industry standards such as ASME B16.5 or EN 1092-1. These standards provide tables that specify the maximum allowable working pressures for different flange materials across a range of temperatures.

Medium Compatibility: Ensuring Chemical Resistance

The type of medium flowing through the piping system plays a significant role in flange selection. Different fluids, gases, or chemical compounds can have varying effects on flange materials, especially at high temperatures. It's crucial to choose a flange material that is compatible with the process medium to prevent chemical attack, stress corrosion cracking, or other forms of degradation.

For instance, in high-temperature steam applications, carbon steel or low-alloy steel flanges might be suitable. However, for services involving corrosive chemicals or acids, more resistant materials like high-alloy stainless steels or nickel-based alloys may be necessary.

Design and Manufacturing Considerations for High-Temperature Forged Flanges

Forging Process: Enhancing Material Properties

The forging process used in manufacturing high-temperature flanges significantly influences their performance. Hot forging, in particular, is preferred for high-temperature applications as it improves the material's grain structure, resulting in better strength and ductility. The forging process also helps eliminate internal defects and ensures a more uniform distribution of alloying elements, which is crucial for maintaining consistent properties at high temperatures.

When selecting high-temperature forged flanges, it's important to consider the manufacturer's forging capabilities and quality control processes. Advanced forging techniques, such as computer-controlled hydraulic presses and precise temperature control during forging, can lead to superior flange quality and performance.

Heat Treatment: Optimizing Mechanical Properties

Heat treatment is a critical step in the manufacturing of high-temperature forged flanges. Proper heat treatment processes, such as normalizing, quenching, and tempering, can significantly enhance the flange's mechanical properties and microstructure. These processes help achieve the desired balance of strength, toughness, and creep resistance necessary for high-temperature applications.

Different alloy compositions may require specific heat treatment protocols to optimize their properties. For example, chrome-moly steels like F11 and F22 typically undergo normalizing and tempering to achieve the best combination of strength and toughness for high-temperature service.

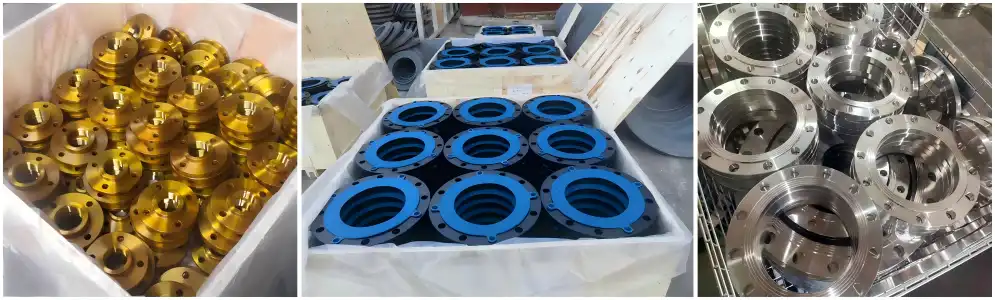

Surface Finish and Dimensional Accuracy

The surface finish of high-temperature forged flanges is crucial for ensuring proper sealing and minimizing the risk of leaks. A smooth, defect-free surface is essential for creating an effective seal with gaskets, particularly in high-temperature applications where thermal cycling can stress the sealing surfaces.

Dimensional accuracy is equally important, as it affects the flange's ability to maintain a proper seal under varying temperature and pressure conditions. Precise machining and strict quality control measures are necessary to ensure that high-temperature forged flanges meet the required dimensional tolerances specified in industry standards like ASME B16.5 or EN 1092-1.

Conclusion

Selecting the appropriate high-temperature forged flange requires a comprehensive understanding of various factors, including material properties, operating conditions, and manufacturing processes. By carefully considering the maximum operating temperature, medium type, pressure ratings, and thermal stability requirements, engineers can choose flanges that ensure safe and efficient operation in extreme conditions. Prioritizing alloy steel materials, understanding the importance of proper heat treatment, and ensuring dimensional accuracy are key steps in this selection process. As industrial applications continue to push the boundaries of temperature and pressure, the importance of making informed decisions in high-temperature forged flange selection cannot be overstated.

FAQs

What is the typical temperature range for high-temperature forged flanges?

High-temperature forged flanges are typically used in applications with temperatures above 400℃, but can withstand much higher temperatures depending on the material.

Why are alloy steels preferred for high-temperature forged flanges?

Alloy steels are preferred due to their superior strength, creep resistance, and thermal stability at elevated temperatures.

How does pressure rating change with temperature for forged flanges?

Generally, as temperature increases, the allowable working pressure of a flange decreases. This relationship is specified in industry standards and manufacturer ratings.

Expert High-Temperature Forged Flange Solutions | QinSteel

At QinSteel, we specialize in providing top-quality high-temperature forged flanges tailored to your specific application needs. Our extensive range of alloy steel flanges ensures optimal performance in extreme conditions. As a leading manufacturer and supplier, we offer expert guidance, competitive pricing, and timely delivery. Contact us at info@sxqinsteel.com to discuss your high-temperature flange requirements and experience our commitment to excellence.

References

ASME B16.5 - Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard

EN 1092-1 - Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN designated

ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys

Mechanical Engineers' Handbook, Volume 1: Materials and Engineering Mechanics

High Temperature Characteristics of Stainless Steels - A designers' handbook series

Corrosion of Weldments - American Welding Society publication