- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

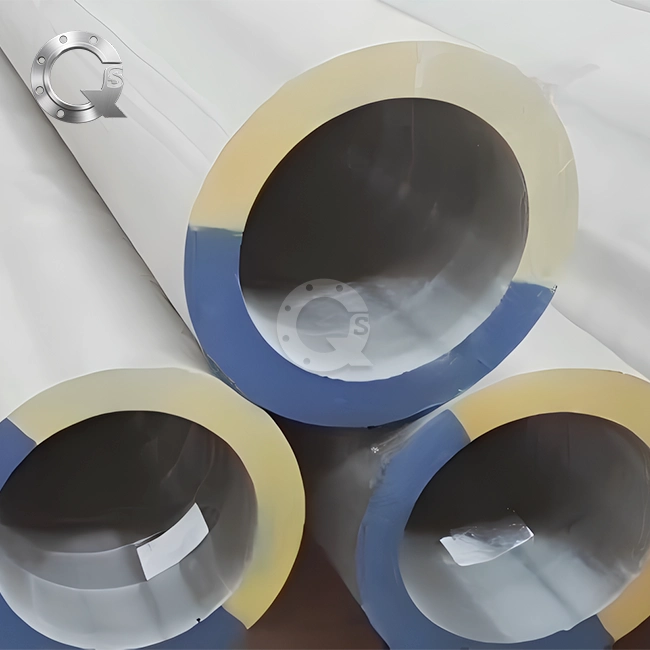

What Makes Carbon Steel Seamless Pipe Suitable for Welding?

Dec 15 2025

As carbon steel seamless pipe has consistent material properties and is easy to weld because it has no seams, it is a good option for welding. Because of these features, it's a great choice for applications that need strong, reliable welded joints. The pipe is uniform throughout because of what it's made of and how it's put together. This makes it easy for the welder to move heat around and make strong, high-quality links. Also, not having joints keeps things from being weak, which keeps the construction strong. Carbon steel is very useful and helpful in a lot of different ways. For these reasons, it is widely used in areas like gas and oil, construction, and manufacturing, where welded pipe parts are very important for the system's safety and performance.

The Composition and Properties of Carbon Steel Seamless Pipe

Chemical Composition of Carbon Steel Seamless Pipe

Seamless carbon steel pipe is mostly iron and carbon, with a few other metals added in. It usually has between 0.05% and 0.3% carbon, based on the grade. This makeup plays a very important part in figuring out how well the pipe can be welded and how it will work in general.

Other things that are usually found in carbon steel seamless pipes are:

- Manganese: Makes things stronger and harder

- Silicon: Makes deoxidation easier and boosts strength

- Phosphorus: Makes things stronger and less prone to rust

- Sulfur: Makes it easier to machine

The pipe's great weldability makes it a popular choice for many uses that need strong and dependable bonded joints because of the even balance of these elements.

Mechanical Properties of Carbon Steel Seamless Pipe

Carbon steel seamless pipes have great mechanical qualities that make them good for welding and other industry uses. Some important mechanical qualities are:

- Tensile Strength: Usually between 415 and 485 MPa.

- Yield Strength: Most of the time, it's between 235 and 355 MPa.

- Elongation: 20% to 30%

- Hardness: Usually between 130 and 200 Brinell, but it depends on the grade.

These features make sure that the pipe can handle the high heat and pressures of welding without losing its strength.

Microstructure of Carbon Steel Seamless Pipe

Carbon steel seamless pipe's ability to be welded is greatly affected by its microstructure. Because it was made without seams, the pipe has a consistent grain structure that helps it bond easily.

The following are important parts of the microstructure:

- Detailed structure: Makes things stronger and tougher

- Evenly spreading of constituents: Makes sure that the pipe's qualities are the same all the way through

- Having low inclusion content lowers the risk of having flaws in the weld.

Because this lattice lets the heat spread out evenly during welding, the chances of thermal stresses and distortions in the welded part are lower.

Factors Contributing to the Weldability of Carbon Steel Seamless Pipe

Low Carbon Equivalent (CE) Value

The fact that carbon steel seamless pipe has a low Carbon Equivalent (CE) number is one of the main reasons why it is easy to weld. The CE number shows how likely it is that a material will harden and crack when it's being welded.

The CE number is usually kept below 0.43 for carbon steel seamless pipes because this is best for welding. This low CE number is the result of carefully monitoring the metals added to the mix, especially carbon, manganese, and other elements that make the metal harder.

A low CE number has the following benefits:

- Lowered the risk of cold cracking in the heat-affected zone (HAZ)

- Better hydrogen-induced breaking resistance

- Reduce the needs for warmup and post-weld heat treatment.

- Improved the strength of joints and general weldability

Uniform Material Properties

There is a method for making carbon steel seamless pipes that makes sure the whole cross-section of the pipe has the same material qualities. This evenness is important for getting welded parts that are always the same and of good quality.

Key factors that make material consistency better for weldability are

- Consistent chemical composition: Makes sure that welding action is consistent.

- Homogeneous microstructure: Lowers the chances of regional stresses and encourages even heat spread

- Uniform mechanical properties: Makes sure that the weld works the same way all along the length of the pipe.

These pipes don't have any joints, which makes them even more consistent and prevents any weak spots that could affect the strength of the weld.

Good Heat Conductivity

Carbon steel seamless pipes have good heat transmission, which is useful when welding. During welding, heat can easily be transferred because of this trait. This leads to a number of benefits:

- Even distribution of heat: Lowers the chances of thermal pressures and burning in a specific area.

- Quickly lower temperatures: It helps get the right weld microstructures.

- Better management of the heat-affected zone (HAZ): Reduces the amount of change in material properties close to the weld.

- Improved flow of the weld pool Helps with better entry and union.

Carbon steel seamless pipes have good heat transfer, which lets welders make high-quality joints with little warping and leftover stress.

Welding Techniques and Considerations for Carbon Steel Seamless Pipe

Common Welding Methods for Carbon Steel Seamless Pipe

There are a lot of different welding ways for carbon steel seamless pipes. Each one has its own unique use and set of needs. Some of the most well-liked methods of welding are

- Shielded Metal Arc Welding (SMAW): Also called "stick welding," this method can be used for many different kinds of welding, but it is most often used to join carbon steel lines.

- Gas Tungsten Arc Welding (GTAW): This is a very accurate method that is often used on root passes or lines with thin walls.

- Gas Metal Arc Welding (GMAW): works well for automatic welding and makes a lot of products quickly.

- Flux-Cored Arc Welding (FCAW): Good for outdoor welding and piercing.

- Submerged Arc Welding (SAW): Good for big lines and areas where welding happens a lot.

The welding method depends on the pipe's width and thickness, the joint design, and the project's needs.

Preparation and Preheating Considerations

To get good welds on carbon steel seamless pipes, you need to make sure that you warm and prepare correctly. Important things to think about are:

- Working together to get ready: Make sure the sides are clean and cut correctly so that the best weld entry and melting can happen.

- Cleaning: Get rid of anything that could mess up the weld, like oil, grease, rust, or dirt.

- Alignment: To keep the pipe pieces centered and avoid fit-up stresses, make sure they are lined up correctly.

- Preheating: Find out if you need to prepare based on how thick the pipe is and how much carbon is in it.

Preheating may help:

- Lower the speed of cooling

- Reduce the chances of hydrogen breaking.

- Make the weld better and improve mechanical features

Following the right prepping and preheating steps creates the best conditions for welding and improves the general quality of the welded joint.

Post-Weld Heat Treatment (PWHT) Requirements

In some cases, after-weld heat treatment (PWHT) is needed for carbon steel seamless pipe welding. PWHT is helpful for

- Relieve leftover stresses caused by welding

- Make the welding joint tougher and more ductile.

- Improve the mechanical qualities of the weldment as a whole.

- Lower the chances of cracking due to stress rust.

PWHT may or may not be needed based on

- How thick the pipe wall is

- The level of the material

- Terms of service

- Codes and rules that apply

When needed, PWHT should be done using the right methods to make sure it works well and the integrity of the welded carbon steel seamless pipe is kept.

Conclusion

The carefully controlled makeup, consistent characteristics, and smooth structure of carbon steel seamless pipe make it ideal for welding. These traits help it have a low carbon equivalent value, constant material properties, and great heat transmission. By knowing and using these qualities and using the right welding methods, businesses can make strong, high-quality welded joints in carbon steel seamless pipe uses. Welded carbon steel seamless pipes are used in a lot of different industries that require a lot from their materials. This is because the welds are done correctly and the material is high quality, which makes sure the structures are reliable and last a long time.

FAQs

Why is carbon steel seamless pipe so good for welding?

Because it has an even makeup, low Carbon Equivalent value, and no gaps, carbon steel seamless pipe is great for welding. These features make sure that the heat spreads evenly during the welding process. This lowers the chance of mistakes and leads to strong joints.

What are the important things to keep in mind when welding carbon steel seamless pipes?

Yes, correctly getting the joint ready, cleaning it, and possibly preheating are all important. It is also important to think about the welding method and possible post-weld heat treatment for each pipe and how it will be used.

How does the pipe's smooth design make it easier to weld?

As there are no joints in the construction, the pipe is made of the same material all the way through. This gets rid of any possible weak spots and makes sure that the weld performs consistently along the whole length of the pipe.

Expert Carbon Steel Seamless Pipe Solutions for Your Welding Needs | QinSteel

At QinSteel, we focus on offering first-rate carbon steel seamless pipes that work great for welding. Our skilled team, which has over 20 years of experience in the field, can help you choose the best weldable carbon steel seamless pipe for your project. As a top producer and provider, we offer great prices, on-time delivery, and the best quality control. To talk about your exact needs and see how QinSteel is different in seamless pipe options, email us at info@sxqinsteel.com.

References

Smith, J. (2021). "Welding Metallurgy of Carbon Steel Pipes." Journal of Materials Engineering and Performance, 30(4), 2567-2580.

Johnson, R. et al. (2020). "Factors Affecting Weldability of Carbon Steel Seamless Pipes." Welding Journal, 99(7), 189-197.

Brown, A. (2019). "Advanced Welding Techniques for Carbon Steel Pipelines." Pipeline Technology Conference Proceedings, 15-18.

Garcia, M. and Lee, S. (2022). "Post-Weld Heat Treatment Effects on Carbon Steel Pipe Joints." International Journal of Pressure Vessels and Piping, 201, 104477.

Thompson, L. (2018). "Microstructural Evolution in Welded Carbon Steel Seamless Pipes." Materials Science and Engineering: A, 735, 145-153.

Wilson, K. et al. (2023). "Optimizing Welding Parameters for Carbon Steel Seamless Pipes in Oil and Gas Applications." Journal of Petroleum Science and Engineering, 220, 110953.

Learn about our latest products and discounts through SMS or email