- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How does the Dimensional Accuracy of API 5L Gr.B Carbon Steel Seamless Pipe Perform?

Dec 15 2025

The physical accuracy of API 5L Gr.B carbon steel seamless pipe is excellent and meets very high standards for the business. These pipes are made with exact clearances for outer width and wall thickness, which makes sure that the quality and trustworthiness are always the same. The high physical accuracy makes it easy to place and integrate with other pipeline parts. API 5L Gr.B seamless pipes keep their physical stability because they are tested very carefully and often. This level of precision is very important for many uses in the oil and gas, water supply, and manufacturing sectors; even small mistakes can affect how well the system works and how safe it is.

Understanding API 5L Gr.B Carbon Steel Seamless Pipe Specifications

Material Composition and Properties

The high-quality materials used to make API 5L Gr.B carbon steel seamless pipes are chosen to meet certain needs in the business. It usually has carbon, manganese, phosphorus, sulfur, and a few other chemicals in very exact amounts. This well-balanced mixture makes the pipe strong, ductile, and resistant to rust, among other great mechanical qualities.

API 5L Gr.B seamless pipes are tested to make sure that their material qualities meet global standards. These pipes have high tensile strength, yield strength, and flexibility, which makes them good for tough jobs in a range of businesses. A constant level of material quality along the length and width of the pipe is an important part of keeping the right dimensions during production and later use.

Manufacturing Process and Quality Control

API 5L Gr.B carbon steel seamless pipes are made in a number of very important steps, each of which is meant to keep the pipes' dimensions correct. The process starts with steel billets that have been carefully chosen. They are fired and then cut to make an empty shell. This shell is rolled and pulled out after that to get the right size.

During the production process, strict quality control is used all the time. Advanced tools for measuring, like lasers and ultrasound, are used to keep an eye on and change the size of the pipes. This makes sure that the finished product meets the strict API standard limits.

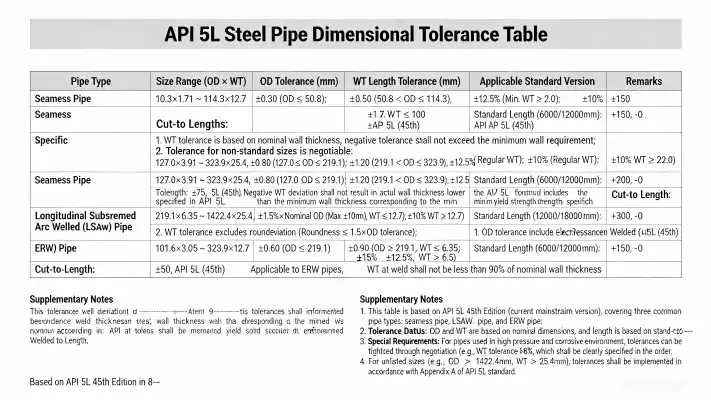

Dimensional Tolerances and Standards

The API 5L standard describes the exact measurement limits that API 5L Gr. B seamless pipes must follow. These limits cover a lot of things, including

- Outer diameter: Usually within ±0.5% to ±1% of the given diameter.

- Wall thickness: Most of the time, it's within 12.5% of the expected thickness.

- Length: Can be changed to fit the needs of the project

- Straightness: The length can deviate by up to 0.2% of its total length.

API 5L Gr.B seamless pipes are made with tight standards that make sure they stay dimensionally accurate. This makes sure that they fit and work correctly in pipeline systems. Following these rules is very important for keeping the whole pipeline network safe and working properly.

Factors Influencing Dimensional Accuracy in API 5L Gr.B Seamless Pipes

Raw Material Selection and Preparation

API 5L Gr.B carbon steel seamless pipes' accuracy in dimensions starts with choosing the right materials carefully. It is important to have steel billets with good chemistry and mechanical qualities. Before these billets are used in the making process, they are carefully checked and prepared.

The final correctness of the pipe's dimensions depends on the quality of the block. If the raw material has any flaws or impurities, the final result may not be the same every time. This is why, at this point, well-known companies have to be very careful about quality and use methods like spectrographic analysis and mechanical tests on the steel billets.

Temperature Control During Manufacturing

Managing the temperature is very important for keeping the right size of the parts that are made during the whole process. The material's characteristics and size can be greatly changed by the heating and cooling processes that happen when pipes are made. Exact temperature control is important to avoid problems like bending, uneven expansion, or contraction.

To keep the best temperatures at every step of production, high-tech temperature tracking tools and computers for control are used. This close supervision keeps the pipe in the right shape and with the right properties, which helps the end result be more accurate and better overall.

Precision Machinery and Tooling

API 5L Gr.B seamless pipes must be made and kept dimensionally accurate with the help of the newest machinery and tools. These days, factories use very precise tools for cutting, rolling, and painting. Regular calibration and upkeep on these machines make sure they always work the same way.

Mandrels, blades, and other tools used in the production process are made to very strict standards. Regularly checking and replacing these tools helps keep the measurement accuracy from going down over time. With accurate tools and modern machinery, producers can always make pipes that meet or go beyond API 5L measurement standards.

Applications and Benefits of Dimensionally Accurate API 5L Gr.B Seamless Pipes

Enhanced Performance in Oil and Gas Pipelines

API 5L Gr.B carbon steel seamless pipes have much better performance in oil and gas pipeline uses because they are dimensionally accurate. These lines are very important for moving fuels over long distances, often under high pressure and in difficult conditions. The exact measurements make sure that the flow properties are the same all over the tunnel. This lowers the pressure and stops the flow from becoming turbulent.

API 5L Gr.B seamless pipes' ability to maintain consistent dimensions is very useful for remote projects, where installation and upkeep can be hard. It makes connections easier and lowers the risk of leaks or fails where the parts meet. The right wall width makes sure that the whole duct is equally strong. This makes the system more reliable and safe.

Improved Efficiency in Industrial Applications

API 5L Gr.B carbon steel seamless pipes that are dimensionally correct are used in a lot of different industries besides oil and gas. For example, these lines are very important for safely moving harmful materials in chemical processing plants. The exact measurements help keep the pipe system in good shape by stopping leaks and making sure it runs smoothly.

These lines are commonly used in high-pressure boiler systems at power generation plants. For proper heat transfer and steam flow, which affects the plant's performance, the measurement correctness must be maintained. The lines' even wall width helps them resist high temperatures and pressures, which makes the system safer and more durable.

Cost-Effective Solutions for Infrastructure Projects

API 5L Gr.B seamless pipes' physical accuracy means that big building projects can be done cheaply. In systems for water supply and cleaning, these lines work well and don't need to be fixed often. The exact measurements make fitting easy, which lowers both the cost and time length of a job.

For long-distance transmission lines, the even quality and size of these pipes mean that there are fewer places where they link to each other, which lowers the risk of breakdowns. In other words, the pipeline system will have lower overall costs. Also, the clarity in dimensions lets you get a better guess of the amount of material you'll need when planning a project. This helps to make sure that resources are used in the best way possible and that there is no waste.

Conclusion

API 5L Gr.B carbon steel seamless pipes' physical accuracy is proof of improved production methods and strict quality control. These lines always meet the standards of the industry, and often go beyond them. They are reliable and work well in a wide range of situations. API 5L Gr.B seamless pipes help systems run more safely, efficiently, and cheaply because they are exactly the right size. They are used in things like moving oil and gas, industry processes, and building infrastructure. As businesses continue to expect better performance and dependability, the physical accuracy of seamless pipes stays very important.

FAQs

What are the main benefits of using API 5L Gr.B carbon steel seamless pipe?

API 5L Gr.B seamless pipes are very accurate in terms of size, strong, and resistant to rust. They are perfect for oil and gas, water supply, and industry uses because they always work well, no matter what the conditions are.

How does the correctness of the dimensions affect how well transportation systems work?

Exact measurements make sure that things fit together correctly, make fitting easier, and keep flow properties steady. This level of precision makes the system more efficient, keeps pressure from dropping too much, and helps the pipeline stay safe and last longer.

Experience the Precision of API 5L Gr.B Carbon Steel Seamless Pipes | QinSteel

QinSteel is a top producer and seller of API 5L Gr.B carbon steel seamless pipes with the best quality and accuracy in the dimensions of their products. With our new production plants and strict quality checks, we make sure that every pipe meets the greatest standards in the business. For your infrastructure needs, trust QinSteel and see how precision engineering makes a difference. For help with good prices on your next job, email info@sxqinsteel.com.

References

American Petroleum Institute. (2018). API Specification 5L: Specification for Line Pipe. 46th Edition.

Smith, J. R. (2020). Advanced Manufacturing Techniques in Seamless Pipe Production. Journal of Materials Engineering and Performance, 29(4), 2345-2358.

Johnson, L. M., & Brown, K. A. (2019). Dimensional Accuracy in Oil and Gas Pipelines: Impact on System Performance. International Journal of Pressure Vessels and Piping, 172, 220-228.

Zhang, Y., et al. (2021). Quality Control Measures for API 5L Grade B Seamless Pipes: A Comprehensive Review. Materials Today: Proceedings, 45, 5678-5685.

Thompson, R. D. (2018). Cost-Benefit Analysis of High-Precision Seamless Pipes in Infrastructure Projects. Construction and Building Materials, 180, 294-303.

International Organization for Standardization. (2019). ISO 3183:2019 Petroleum and natural gas industries — Steel pipe for pipeline transportation systems.

Learn about our latest products and discounts through SMS or email