- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

SANS 1123 Flange

SANS 1123 Flange: High-Performance Solutions for Industrial Pipelines

Xi'an QinSteel Trading Co., Ltd is a trusted global manufacturer and supplier of precision-engineered SANS 1123 Flange solutions. With a GMP-certified factory and large-scale inventory, we deliver reliable, high-pressure flanges tailored to meet South African National Standards (SANS 1123) and global project requirements.

Product Overview

The products are designed for demanding applications in oil, gas, water treatment, and industrial piping systems. These flanges comply with strict pressure ratings (250 kPa to 4000 kPa) and come in weld neck (WN), slip-on (SO), plate, screwed, loose, blank, and integral types. Built to withstand corrosive environments, they ensure leak-free performance in extreme temperatures and high-stress conditions.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Materials & Durability

- Materials: Carbon steel (A105, A36), stainless steel (304/316), duplex alloys (F51, F53, F55).

- Certifications: Compliant with SANS 1123, ASME B16.5, API 6A, EN 1092-1.

- Surface Treatments: Hot-dip galvanizing, epoxy coatings, shot blasting for enhanced corrosion resistance.

Why Our SANS 1123 Flanges Stand Out?

1. Built for Extreme Conditions

Engineered to handle high-pressure oil and gas pipelines, our flanges undergo rigorous testing (NDT, PMI) to ensure weld integrity and material traceability. The tapered hub design reduces turbulence, improving flow efficiency in refinery and offshore systems.

2. Customization Without Compromise

Need non-standard dimensions or sour-service alloys? Our OEM/ODM services provide tailored solutions, including specialized coatings and sizes for niche applications.

3. Faster Lead Times

With 15,000+ tons of annual production capacity and regional warehouses in the UAE, USA, and Singapore, we cut delivery times by 30%—even for bulk orders.

4. Global Compliance

Every SANS 1123 Flange meets ISO 9001, CE, PED, and API Q1 standards. Dual-certified options (e.g., GOST or ABS) are available for region-specific projects.

Applications

- Oil & Gas: High-pressure pipelines, refinery equipment.

- Water Treatment: Corrosion-resistant connections for chemical processing.

- Industrial: HVAC, power plants, and mining infrastructure.

Quality Assurance

Our in-house NDT lab conducts:

- Dimensional Checks: ±0.05mm tolerance.

- Pressure Testing: Validated up to 1.5x rated pressure.

- Material Analysis: Spectrometer testing for alloy composition.

Secure Packaging & Delivery

Triple-layer protection (wooden crates + waterproof film + shock-absorbent filler) ensures damage-free transit. Carbon-neutral shipping options align with ESG mandates.

Why Choose Xi'an QinSteel?

- 10+ Years of Expertise: R&D-driven designs optimized for extreme environments.

- Full Certification Portfolio: ISO, CE, API, and more.

- Bulk Order Ready: 50,000+ units in stock for urgent demands.

Quality Control

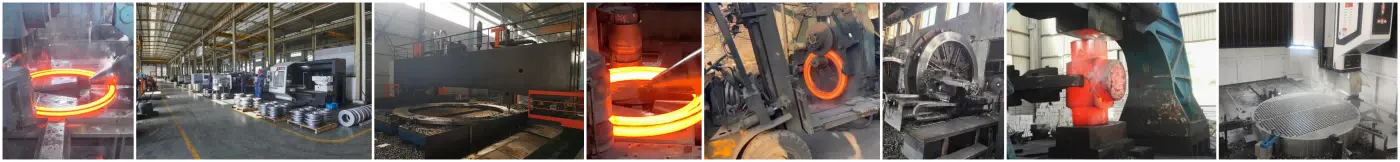

Factory Equipment

Shipping Packaging

FAQs

Q: Can you customize products for high-H2S environments?

A: Yes! We offer super duplex or Inconel variants for sour-service applications.

Q: What certifications do your flanges have?

A: All products comply with ISO 9001, CE, and SANS 1123. Regional certifications (e.g., GOST) are available on request.

Q: How do you ensure quality consistency?

A: Our GMP-certified facility uses CNC machining and automated forging, with 100% testing before shipment.

Q: What’s the lead time for 1,000 units?

A: Standard orders ship in 7–15 days. Expedited options reduce this to 5–7 days.

Q: Do you provide samples?

A: Yes—contact us to request samples for material verification.

Contact Us

Email info@sxqinsteel.com with your specifications (material, size, quantity) for competitive pricing and technical support.

Trust Xi'an QinSteel for SANS 1123 Flange solutions that combine precision, durability, and fast global delivery.

Learn about our latest products and discounts through SMS or email