The ASME B16.5 slip-on flange is a very important part of modern piping systems. It provides solid connections in a wide range of industries. These flanges make it easier to put together pipelines because of their unique design, which lets the pipe go through the flange hub before welding. Slip-on flanges are made to strict ASME B16.5 standards and can be used with a wide range of pressure values from Class 150 to Class 2500 and sizes from ½" to 24". They are popular because they are cheap and work well in environments with moderate pressure. This makes them an important tool for procurement professionals who need to find balanced solutions between performance and budget limits.

Understanding ASME B16.5 Slip-On Flange

The ASME B16.5 standard sets the rules for the size and performance of pipe flanges. It creates consistent guidelines that make sure everything will work together, no matter where it's from. Slip-on flanges have a special hub design that makes them different. This design lets the pipe be inserted before welding is done on the inside and outside of the connection point.

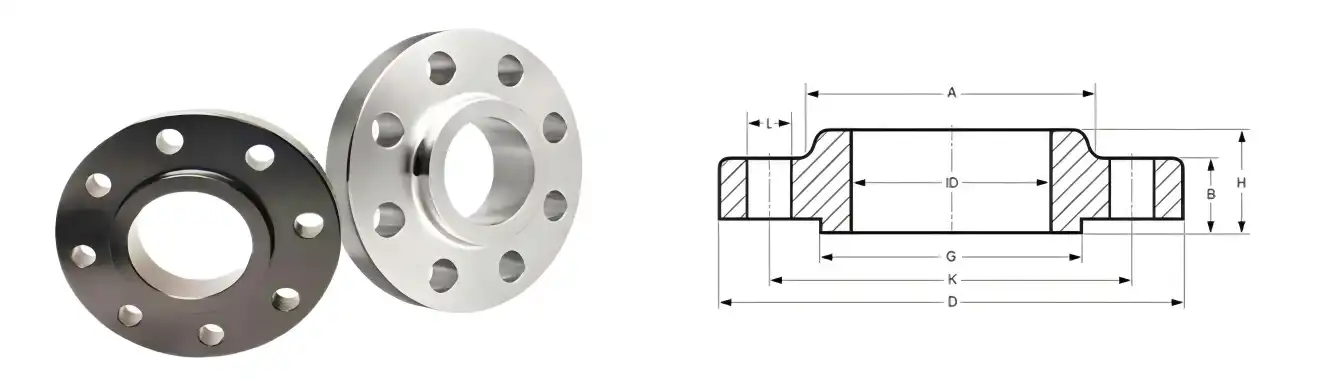

Design Specifications and Dimensions

These flanges have dimensional tolerances that ensure a perfect fit and efficiency. The hub diameter is usually about 1/8 inch larger than the pipe's outer diameter. This makes fitting easier and keeps the structure strong. Pressure class ratings decide on the total size, flange thickness, and bolt hole patterns. Class 150 flanges work well when there isn't much pressure, and Class 2500 flanges are made for places with a lot of pressure.

Material Options and Properties

The material that is used for the plate has a big effect on how well it works and how long it lasts. For normal use, carbon steel types like A105 work well as an all-around choice. A350 LF2, on the other hand, works better at very low temperatures for cryogenic services. In harsh chemical settings, stainless steels like A182 F304 and F316 are better at resisting rust. Advanced duplex metals like F51, F53, and F55 are great for offshore and sour gas uses because they are very strong and resistant to corrosion.

Installation Requirements and Best Practices

A good install makes sure that connections are leak-proof and function is top-notch. The slip-on design makes it easier to line up compared to other flange types. This keeps the link reliable, cuts down on installation time, and avoids having to do things over again. Welding must be done according to qualified methods to get full penetration and avoid points of high stress that could weaken the system.

Advantages and Limitations of ASME B16.5 Slip-On Flanges

Engineers make good choices about ASME B16.5 SO flange selection for certain uses when they know about both the strengths and weaknesses of flanges. Slip-on flanges have very useful benefits but also some problems that need to be thought about when designing them.

Key Advantages in Industrial Applications

Slip-on flanges are useful in many industries because of their main benefits:

- Affordable Way to Solve the Problem: Slip-on flanges are weld neck flanges' cheaper cousins. They meet basic performance needs, so they're a great choice for projects that need to save money.

- Installation Efficiency: The slip-on design makes it easier to line up the pipes and simplifies the welding process. This leads to quicker installation and lower labor costs.

- A lot of different ways to face: Can be gotten with RF, FF, RTJ, M&F, and T&G facings to meet different gasket and sealing needs.

- Maintenance Accessibility: The design makes it easy to take the system apart in working facilities so that it can be fixed and parts can be replaced.

These benefits lead to real-world helps for project managers who need to keep an eye on performance standards, cost limits, and installation schedules.

Operating Limitations and Constraints

Slip-on flanges have certain issues that affect how they can be used, even though they are helpful in some ways. They can't be used in very hot or very high-pressure situations because of temperature and pressure limits, respectively. The welding setup makes possible stress concentration spots that might shorten the fatigue life compared to weld neck options. Also, the slip-on design could let the pipe move a little bit while it's being installed, so the person doing it needs to be very careful about how they line everything up and weld it.

Comparison with Other ASME B16.5 Flange Types

You need to know how slip-on flanges are different from other ASME B16.5 choices in order to pick the right flange type. Each type of flange has its own pros and cons based on how it will be used, the conditions it will be used in, and cost factors.

Structural Performance Differences

Weld neck flanges are better at supporting structures because their tapered hub form moves stress from the pipe to the flange face. This form gives them the strength needed for high-pressure, high-temperature situations. For smaller pipes, socket weld flanges work really well. On the other hand, blind flanges are good for system ends or test points because they close off the pipe completely.

Installation and Cost Considerations

Slip-on flanges usually take 30% less time to weld than ASME B16.5 slip on flanges. This saves a lot of time and money on big jobs. The easier welding makes it simpler to get done, which could lower the cost of projects because it doesn't require as many skilled welders. But this benefit in cost has to be weighed against the needs for efficiency because weld neck flanges are worth their higher price in important uses.

Pressure and Temperature Capabilities

Slip-on flanges work well for low pressures, but weld neck flanges are better for high-pressure situations because they spread the stress more evenly. Also, the temperature ranges that flanges can handle vary. Slip-on flanges usually work only in low temperature ranges, while weld neck designs have better thermal performance.

Procurement Guide for ASME B16.5 Slip-On Flanges

To purchase things successfully, you need to know what affects the price, quality, and delivery time. Material grades, flange sizes, and pressure classes are among the most important factors that affect cost. Specialty metals are more expensive than standard carbon steel choices.

Supplier Evaluation and Quality Assurance

Trustworthy vendors have a lot of different certificates, such as ISO 9001 for quality management systems and API and NACE compliance for standards in those industries. For important uses, material traceability gets very important, making sure that the whole process from the source of the raw material to the end inspection is recorded. For important tasks, third-party inspection services make sure the work is really good.

Bulk Purchasing and Lead Time Optimization

Buying in bulk usually saves a lot of money, and mass discounts are usually given at the 1,000, 5,000, and 10,000-piece levels. For normal specs, the standard amount of time to wait is 4 to 8 weeks. If you need to use rare materials, though, you might have to wait for 12 to 16 weeks. People with emergency needs can often get help quickly if they are willing to pay extra.

QinSteel's Comprehensive Service Approach

At QinSteel, we use our more than 20 years of experience in the business to provide amazing value in slip-on flange procurement. ASME B16.5, API 6A, ISO 9001, and CE/PED compliance are all parts of our global certification collection that make sure goods meet tough global standards. We keep a lot of inventory in the different grades A105, A350 LF2, and stainless steel variants A182 F304/F316. This lets us meet your immediate needs quickly and gives you great prices on bulk orders.

Conclusion

ASME B16.5 slip-on flanges are the best choice for piping systems with moderate pressure because they offer the best mix of performance, cost, and ease of installation. Their adaptable form meets the needs of a range of industries and always works well in the oil and gas, chemical processing, and power generation sectors. Knowing their pros and cons helps people make smart buying choices that save money on projects and improve overall performance. The key is to make sure that flange specs and real application needs are the same, taking into account things like pressure, temperature, and chemical compatibility. When these flanges are properly chosen and fitted, they provide reliable service and keep costs low compared to more complicated flange designs.

FAQs

For ASME B16.5 slip-on flanges, what are the different pressure groups that can be used?

ASME B16.5 slip-on flanges come in pressure classes from 150 to 2500. The working pressures they can handle range from 230 psi to 6,170 psi, based on the temperature and material requirements. Flanges of Class 150 and 300 are used for most common industrial uses. For oil and gas operations with high-pressure systems, Class 600 and up are used.

How hard is it to put slip-on flanges compared to weld neck flanges?

Slip-on flanges make installation a lot easier because they let the pipe go through the flange hub. This means that, unlike weld neck flanges, you don't need to cut and angle the pipe exactly right. This design usually lowers the time needed for welding by 30% and requires less skilled welding knowledge. Because of this, they are cost-effective for projects with mild pressure needs.

Can slip-on flanges be used in situations with high temperatures?

Slip-on flanges can handle high temperatures, but they don't work as well as weld neck flanges because of stress buildup at the weld joints. In normal carbon steel, they work well in temperatures up to 400°F. For certain uses, stainless steel and alloy materials can handle higher temperatures.

Partner with QinSteel for Your ASME B16.5 Slip-On Flange Requirements

QinSteel is your reliable ASME B16.5 slip-on flange provider because it brings together decades of engineering knowledge with a wide range of manufacturing capabilities. No matter the size of the project, our global logistics network, large material collection, and ability to respond quickly make sure that deliveries always happen on time. Our technical team can help you choose the right flange by giving you expert advice on standard specs or custom OEM solutions. For your important piping jobs, see what good manufacturing and quick service can do. For full specifications and competitive quotes, email info@sxqinsteel.com .

References

American Society of Mechanical Engineers. "ASME B16.5: Pipe Flanges and Flanged Fittings NPS 1/2 Through NPS 24 Metric/Inch Standard." 2020.

Bickford, John H. "Gaskets and Gasketed Joints, Second Edition." CRC Press, 2016.

Mohitpour, Mohammad, et al. "Pipeline Design & Construction: A Practical Approach, Third Edition." ASME Press, 2007.

Nayyar, Mohinder L. "Piping Handbook, Seventh Edition." McGraw-Hill Professional, 2000.

Singh, Karan P. "Mechanical Engineering Design of Process Systems: Volume 2 - Shell-and-Tube Heat Exchangers, Rotating Equipment, Bins, Silos, Stacks." Gulf Publishing Company, 1995.

Winkel, Philip. "Flanged Joints and Gasket Selection: A Designer's Guide." Professional Engineering Publishing, 2002.