- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Lap Joint Flange ASME B16.5

Premium Lap Joint Flange ASME B16.5 for Reliable Pipeline Performance

When you need durable, compliant flanges for high-pressure oil, gas, or petrochemical systems, our Lap Joint Flange ASME B16.5 delivers unmatched precision. Designed to meet strict ASME standards, these flanges ensure leak-proof connections, easy alignment, and long-term reliability in demanding environments. With corrosion-resistant materials like stainless steel (F304/F316) and duplex alloys, they’re ideal for offshore platforms, refineries, and chemical plants.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Why Our Lap Joint Flanges Stand Out?

1. ASME-Certified Durability

Every flange undergoes 100% dimensional checks and non-destructive testing (UT/RT) to guarantee compliance with ASME B16.5 tolerances.

2. Global Compliance Made Simple

Pre-certified for PED, CE, and NACE MR0175, reducing paperwork delays for EU, Middle Eastern, or offshore projects.

3. Rapid Customization

Modify bore sizes, face finishes, or materials – no MOQ penalties. Prototypes ready in 15 days.

4. Pre-Stocked Inventory

Over 10,000 units (½"–24") available for immediate dispatch, minimizing downtime during emergency maintenance.

Ideal Applications

- Oil & Gas Pipelines: Handles Class 2500 pressure in sour (H2S) environments.

- Petrochemical Plants: Resists pitting from chlorides and acids.

- Marine Systems: Duplex steel options prevent saltwater corrosion.

Material Traceability You Can Trust

We provide digital mill test reports (MTRs) for every batch, ensuring full material traceability from raw steel to finished flange. Choose from Lap Joint Flange ASME B16.5:

- Carbon Steel: Cost-effective for non-corrosive systems (ASTM A105).

- Stainless Steel: For acidic/alkaline environments (A182 F316).

- Duplex Alloys: Superior strength in subsea applications (F51/F53).

Why Choose Xi'an QinSteel?

✅ 20+ Years of Expertise: Specialized in ASME B16.5 flanges since 2003.

✅ ISO 9001-Certified Factory: Rigorous QC protocols and GMP-grade machining.

✅ Agile Logistics: Industrial packaging + global shipping partners.

Quality Control

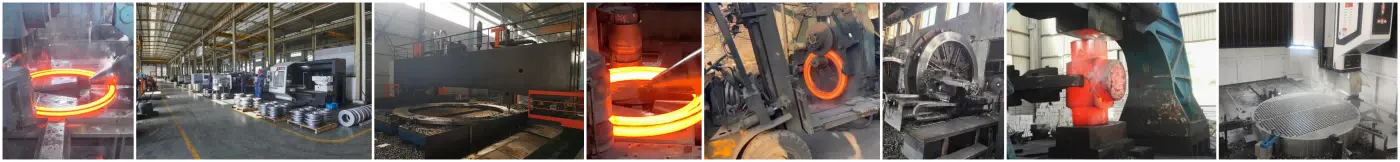

Factory Equipment

Shipping Packaging

FAQ

Q: Can you ship product to remote oilfields?

A: Yes! We use reinforced wooden crates and partner with DHL/FedEx for urgent deliveries.

Q: Do you offer NACE MR0175-certified flanges?

A: Absolutely – critical for sour service pipelines. Specify this requirement in your RFQ.

Q: What’s the lead time for 500 custom flanges?

A: 4–6 weeks for tailored designs. Stock orders ship in 7 days.

Contact Us

Email your project specs (size, material, pressure class) to info@sxqinsteel.com for a competitive offer within 4 hours.

Xi'an QinSteel Trading Co., Ltd – Your Partner in High-Performance Lap Joint Flange ASME B16.5 Solutions.

Learn about our latest products and discounts through SMS or email