For high-pressure uses, weld neck pipe flanges are better than slip-on ones because they spread stress more evenly and make the structure stronger. Their butt-welded, tapered hub design makes them work best when the pressure is on. This makes them the go-to choice for important pipes in the power generation, oil, gas, and petrochemical sectors.

In industrial systems, pipe flanges are very important for making sure that pipes, valves, and other parts are safely connected. Choosing the right flange type is very important in high-pressure situations where safety, performance, and durability can't be compromised. This article talks about weld neck and slip-on flanges and how they are made, how they work under pressure, how they are installed, and how they are bought. The goal is to give buying and engineering experts useful information that keeps the pipeline safe and cuts costs while meeting global industry standards.

Understanding Weld Neck and Slip-On Flanges

Weld neck and slip-on flanges are two very different ways to connect pipelines. They each have their own unique structure and functional traits. Knowing these differences is very important when it comes to choosing the best kind of plate for certain jobs in the industry.

Structural Design and Construction

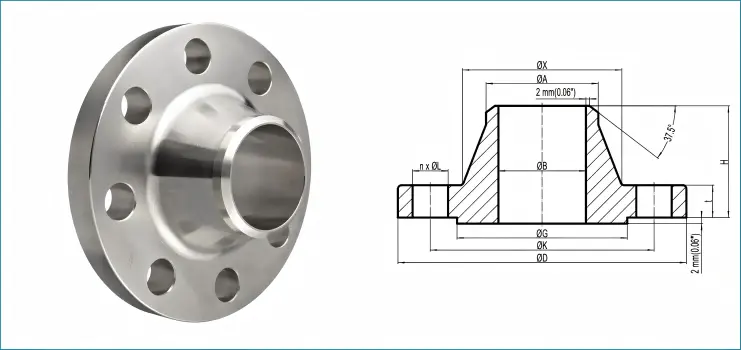

Weld neck flanges have a long, sloped hub that butt-welds straight to the pipeline. This makes a smooth transfer from the pipe to the flange. This design gets rid of sharp corners and other places where stress can build up and hurt the pipes. The tapered hub gets thicker slowly from the pipe wall to the flange face. This makes the whole connection share the stress equally.

On the other hand, slip-on flanges slide over the pipe's outside diameter and need two welds: one at the end of the pipe and one at the back of the flange. This setup makes it more likely that stress will build up where the welds cross, which makes it a worse choice for situations with extreme pressure.

Material Specifications and Standards

Both kinds of flange are made from similar things, like carbon steels A105 and A350 LF2, stainless steel A182 F304 and F316, and specialized duplex steels for corrosive settings, like F51, F53, and F55. These materials meet tough global standards, such as ASME B16.5, API 6B, EN 1092-1, and JIS B2220. This makes sure they can be used in similar ways across industries around the world.

Performance Comparison: Which Flange Performs Better Under High Pressure?

The most important changes between these two flange types can be seen when they are used under very high pressure. When applications are demanding, engineering research and field experience show that weld neck designs are always better.

Stress Distribution and Pressure Handling

Weld neck pipe flanges can withstand pressure levels up to Class 2500 (PN 400) thanks to their tapered hub design, which also improves stress distribution. The smooth transition from pipe to flange gets rid of sharp edges that create stress concentration spots. This greatly lowers the risk of catastrophic failure.

Slip-on flanges usually work well up to Class 600 grades, but they get more likely to fail at higher pressures. The two-weld setup produces places where stress is concentrated and fatigue cracks can start, especially when there is pressure loading that happens over and over again, which is common in industrial operations.

Leak Prevention and Seal Integrity

The ability to avoid leaks depends on the strength of the pipe-to-flange connection and the even distribution of bolt loading across the flange face. Weld neck designs keep the seal working right by making sure that the bolt loading stays the same, even when there are changes in temperature and pressure.

Practical Installation and Application Considerations

These flange types have very different installation and usage requirements, which affects the schedule, cost, and reliability of the job. Knowing these useful facts makes it easier to choose flanges that fit the needs of the business and the budget.

Installation Complexity and Requirements

For butt welding neck flanges to join neck flanges, the pipe must be carefully readied and skilled welders must be hired. The process includes beveling the end of the pipe, getting the right alignment, and doing a single circumferential weld that meets very high standards for quality. This method takes more time and skill, but it makes the link stronger and more reliable.

Slip-on flanges make installation easier, which shortens the time needed to put everything together and doesn't take as much skill. The flange hub fits over the pipe, and the two only need to be roughly lined up before welding. This ease of use makes them a good choice for jobs where there isn't much time or access to certified welders.

Industry Application Preferences

Important business fields always prefer weld neck designs when the stakes are high. Weld neck flanges are very important for safety and environmental protection in oil and gas activities, especially on offshore platforms and in high-pressure transfer systems. Power generation sites use these WN pipe flanges in steam systems with very high temperatures. If these systems fail, they could cause very bad damage to the equipment or hurt the people who work there.

Procurement Insights: Making the Right Choice for Your Business

When making procurement choices, one must ensure compliance with industry standards and operational needs, weigh short-term costs against long-term value, and find a balance. People who buy things smartly look at the total cost of ownership instead of just the price they pay at the store.

Cost Analysis and Value Proposition

Weld neck flanges have higher upfront costs because they are hard to make, but they are usually better in terms of total cost of ownership because they need less upkeep and last longer. The strong design reduces the need for unexpected downtime and replacement costs, which can have a big effect on how businesses run.

Slip-on flanges are cheap at first, which makes them a good fit for jobs that need to save money. But if you use them in demanding situations, their low pressure capability and high maintenance needs might make them more expensive over time.

Supplier Selection and Quality Assurance

Choosing providers with the right certifications makes sure the products are reliable and follow the rules. ISO quality control systems and full material traceability documentation are used and provided by good manufacturers. Getting goods straight from the factory often helps with quality control and expert support more than getting them from distributor networks.

QinSteel: We are your trusted source for high-quality weld neck pipe flanges.

Xi'an QinSteel Trading Co., Ltd is a top global supplier of high-performance pipeline parts. They have over 20 years of experience in the business serving customers in the Americas, Africa, Europe, and Southeast Asia. We are the best choice for difficult industrial uses because of our wide-ranging manufacturing skills and dedication to quality.

Advanced Manufacturing Capabilities

Our new production facilities use both modern CNC machining and strict quality control methods to make weld neck pipe flanges that are better than the rest. Every flange is put through a full test that includes checking the material, measuring the dimensions, and making sure it can handle the pressure. This is done to make sure that it works perfectly in important uses.

Our products include all of the specifications that current industrial systems need. We make WN pipe flanges of all sizes, from ½" to 60", and with pressure values from Class 150 to Class 2500 (PN 6 to PN 400). For the material, you can choose carbon steel grades A105 and A350 LF2, stainless steel alloys A182 F304 and F316, and specialized duplex steels F51, F53, and F55 for tough conditions where corrosion happens quickly.

Quality Assurance and Compliance

Our all-around quality management system makes sure that these foreign standards are always followed: ASME B16.5, API 6B, EN 1092-1, BS 4504, and JIS B2220. Every production batch gets a lot of paperwork, like test results, reports on the size of the parts, and certificates for the materials. This is done to meet the customer's quality standards and follow the rules.

Among the more advanced tests are verification of chemical makeup by spectrometers, laser scanning to check dimensional accuracy, and hydrostatic testing at 1.5 times the pressure the object is rated for. During the manufacturing process, non-destructive testing procedures check that the welds are strong and the materials are sound.

Conclusion

For high-pressure applications, weld neck flanges are definitely the better choice over slip-on flanges because they handle stress and pressure better and are more reliable over time. Slip-on flanges are easy to install and cheap at first, but weld neck pipe flanges hold everything together and help with performance in important industry settings. Better links cost less to keep up, are safer, and are more reliable. When the integrity and performance of a pipeline can't be compromised, people who work in engineering and make buying decisions should put weld neck flanges at the top of their lists.

FAQs

Why are weld neck flanges better for uses with a lot of pressure?

Weld neck flanges are great for high-pressure uses because their tapered hub design makes for smooth stress distribution from the pipe to the flange. Butt welding the two pieces together gets rid of the stress concentration points that are common in slip-on designs. This allows for pressure ratings of up to Class 2500 while keeping the leak resistance and strength at a high level.

Can slip-on flanges be safely used in pipes where pressure is very important?

If you use the right welding methods and quality control steps, you can easily use slip-on flanges in moderate pressure situations up to Class 600. But their dual weld design creates spots that are stressed, making them not a good choice for very high pressure situations or uses where failure would be very bad.

How do the materials used affect the flange's ability in a range of settings?

The material that is used for the plate has a big effect on how well it works and how long it lasts. Carbon steel types, such as A105, work for most purposes. On the other hand, A182 F316 stainless steel is better at resisting corrosion. Duplex steels F51, F53, and F55 work much better in places that are very acidic, like offshore oil platforms or chemical processing plants.

Partner with QinSteel for Superior Pipeline Solutions

QinSteel's weld neck pipe flanges are the best in the business. They meet the toughest standards and offer great value thanks to our extensive production knowledge and ability to source materials from around the world. Our expert team is ready to help you choose the right materials, optimize pressure ratings, and come up with custom specs that meet the needs of your application.

Let your next project see the difference that two decades of excellent production can make. Our professional quality management system, large stock, and ability to produce quickly will keep your pipeline projects on schedule and meet the highest performance standards. Our knowledge of weld neck pipe flanges means that we can always give you the right help, whether you need standard ASME B16.5 specifications or custom alloys for particular uses.

Are you ready to improve your pipeline procurement plan with flanges that are reliable and work well? Email info@sxqinsteel.com to talk about your needs with our technical experts and get a full price.

References

American Society of Mechanical Engineers. ASME B16.5-2020: Pipe Flanges and Flanged Fittings NPS 1/2 Through NPS 24 Metric/Inch Standard. New York: ASME Press, 2020.

Bickford, John H. and Nassar, Sayed. Handbook of Bolts and Bolted Joints. Third Edition. Boca Raton: CRC Press, 2018.

Harvey, John F. Theory and Design of Pressure Vessels. Fourth Edition. New York: Van Nostrand Reinhold, 2019.

Kannappan, S. Introduction to Pipe Stress Analysis. Second Edition. New York: John Wiley & Sons, 2017.

Moss, Dennis R. and Basic, Michael. Pressure Vessel Design Manual. Fifth Edition. Oxford: Butterworth-Heinemann, 2021.

Zahedi, Ahmad R. and Smith, Robert K. Flange Joint Design and Analysis for High-Pressure Pipeline Systems. Journal of Pressure Vessel Technology, Volume 145, Issue 3, 2023.