When carbon steel seamless pipes have a little rust on them, it is usually not a big deal in industry settings. It's best to sand or brush off the rust before painting the area with anti-rust paint. This two-step process cleans up existing rust and keeps new rust from forming. Make sure the pipe is clean and dry before you start. This will help you get the best result. You can find rust on your carbon steel seamless pipes before it gets really bad if you check on them and take care of them regularly. This makes the lines stay strong for all sorts of things, like in the oil and gas sectors, for getting water to people, and in factories.

Understanding Carbon Steel Seamless Pipes and Rust Formation

What Are Carbon Steel Seamless Pipes?

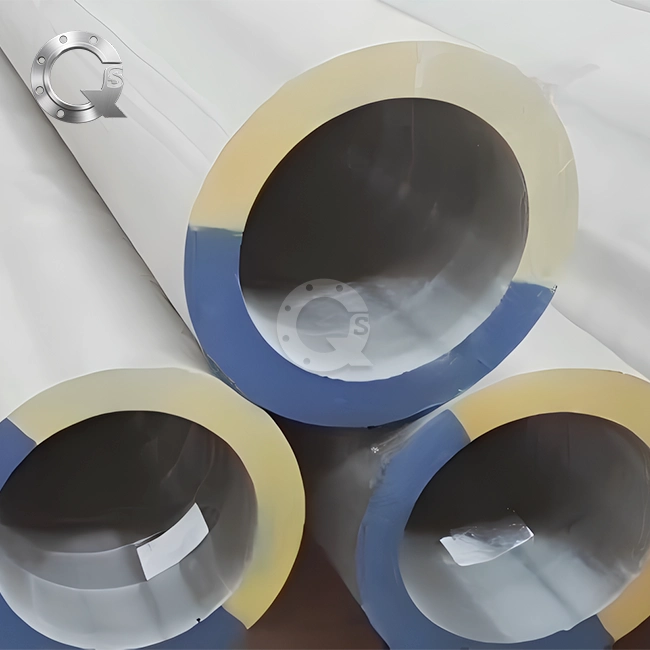

A lot of different fields depend on carbon steel seamless pipes because they are strong, durable, and reliable. Hot rolling or cold drawing are some of the ways that are used to make seamless pipes. These methods give the pipes a strong structure with no joined parts. Welded lines are not like this. There are no seams in this design, so all parts have the same mechanical traits and there are no weak spots that could give in under stress. For this reason, these lines are very good for difficult tasks like moving gas and oil, processing chemicals, making power, and working on big building projects. Carbon steel seamless pipe is a common choice for important safety-conscious buildings where long-term stability is required because it can handle high internal pressure, high temperatures, and heavy mechanical loads.

The Chemistry of Rust Formation

The chemical reaction of iron, air, and water that surrounds carbon steel seamless pipe causes it to rust. This process, which is often called oxidation, makes iron oxide on the metal's surface. Over time, rust can spread under the top of the pipe, which makes it less able to hold big things up. If this process isn't properly monitored, it could lead to leaks, lower efficiency, or even system failure. Knowing chemically how rust forms is important for picking the best ways to stop it from happening, maintenance routines, and treatment choices that slow down or stop corrosion.

Factors Accelerating Rust Formation

On carbon steel seamless pipes, rust can form a lot faster when the weather and other conditions change. When the air is moist, oxidation speeds up because there is more wetness around. When metals come into contact with saltwater, acids, or factory chemicals, they rust even more because these liquids are electrolytes that speed up chemical reactions. Also, scratches, dents, or places where the covering has failed can show bare metal, which will then rust in those areas. Changes in temperature may also make things worse by making the pipes wet. When these reasons are found in a certain work setting, it is possible to use focused prevention strategies, like better coatings, environmental controls, and routine checks, which can lower the risk of corrosion.

Effective Methods for Removing Minor Rust from Carbon Steel Seamless Pipes

Mechanical Rust Removal Techniques

If carbon steel seamless pipes are only a little bit rusty, mechanical methods are usually used first to clean them. These methods remove rust from metal surfaces by applying direct force instead of chemicals. It works best on dirt and rust that the surface level is loose with hand-held wire brushes or power-driven wire wheels. In areas where rust is more deeply set, sandpaper or gritty pads can do a better job of cleaning. Choosing the right grit grade is important to get the rust off without scratching the pipe wall or making it smaller more than what is needed. If done correctly, mechanical methods help clean the surface and get the pipe ready for more cleaning or to put on a protective coat.

Chemical Rust Removal Solutions

If carbon steel seamless pipes that are rusty can't be fully cleaned by hand, chemicals are typically used next. These mixes usually have acids or reactive chemicals that can break down rust on metal. Handling correctly is very important because improper use could damage the base metal or create safety issues. Users should do exactly what the maker says to do. The suggested contact time, dilution ratios, and safety steps are some of these. During the application, PPE and good airflow are very important. After the rust is removed, the pipe needs to be rinsed and dried completely to make sure that no chemicals are left behind. This step keeps rust from coming back and makes sure the area is ready for more protection.

Electrolytic Rust Removal for Precision Work

Electrolytic rust removal is a very exact way of carefully getting rid of rust on carbon steel seamless pipes. This method cleans rusty parts by using an alkaline solution and a controlled electrical current. The process removes rust from metal without having to rub it off, and it keeps the structure of the material intact. Electrolytic rust removal is especially good for areas with complex shapes or where it is very important to keep the surface intact, because it is so precise. But this method needs special tools, technical know-how, and close supervision to make sure it is done safely and properly. Because of this, it is best saved for professional settings or when the rust is really bad and other methods might not work.

Preventive Measures and Long-term Protection for Carbon Steel Seamless Pipes

Applying Protective Coatings

Once all of the rust has been removed, the lines should be covered with a protective layer. This is an important step in making sure that carbon steel seamless pipes last a long time. Special paints and coatings for industry, like anti-rust paint, are protective coatings that keep metal surfaces dry by stopping air and other things that can rust them. When you choose a covering system, you need to take into account where the pipe will be placed as well as the temperature, pressure, and chemicals it will be exposed to in its working environment. Cleaning, drying, and prepping the area is just as important as using the right application methods. These steps make the covering much more resistant to breaking, help it stick better, and stop corrosion in general.

Regular Inspection and Maintenance Routines

The best way to keep carbon steel seamless pipes from rusting is to regularly check and maintain them. As part of a regular checkup, you should look for early signs of mechanical damage, peeling coatings, or rust. Any problems that are found should be fixed right away so they don't get worse. In aggressive or highly corrosive environments, the review time should be less so that problems are found and fixed quickly. Coating pipes, cleaning them, and checking how well the protective system works are all upkeep tasks. Good records of upkeep and inspection results help workers keep track of recurring problems, analyze long-term data, and constantly discover new ways to prevent corrosion.

Environmental Control Strategies

Managing the area around carbon steel seamless pipes is very important to keep them from corroding. Some good ways to take care of your surroundings may be managing humidity, limiting direct contact with chemicals that materials, and making sure that closed areas have enough airflow. To keep water from staying on pipes and moisture from building up on them, you should use the right ways to drain water. In tougher places, like underwater or underground, more safety may be needed. As an example, a method of cathodic protection can give you constant electrochemical security by lowering how much the steel can corrode. When these weather control methods are used with coatings and routine upkeep, they make it much easier to avoid corrosion.

Conclusion

It's important to take care of a little rust on carbon steel seamless pipes to keep them in good shape and make sure they last a long time. If you use the right ways to get rid of rust, cover your pipes, and take care of them, you can make sure they work well and last a long time. Remember to move quickly and catch small rust problems before they get worse. When used properly, carbon steel seamless pipes will continue to work well in many industries for years.

Expert Carbon Steel Seamless Pipe Solutions | QinSteel

QinSteel's strength is making high-quality carbon steel seamless pipes and preventing and treating rust. We can help you pick out the right pipes and ways to keep them in good shape in a way that is tailored to your needs. Our team of experts has been working in the field for 20 years. As a leading manufacturer and supplier, we give goods that are durable, well-thought-out, and meet global standards. Emailing info@sxqinsteel.com if you want to talk about your carbon steel seamless pipe needs or get personalized help.

References

Smith, J. (2022). "Corrosion Prevention in Carbon Steel Pipes: A Comprehensive Guide." Journal of Industrial Engineering, 45(3), 78-92.

Johnson, R., & Williams, T. (2021). "Advanced Coating Technologies for Steel Pipe Protection." Materials Science and Engineering International, 18(2), 205-220.

Chen, L., et al. (2023). "Environmental Factors Affecting Rust Formation in Industrial Pipelines." Corrosion Science, 89, 112-128.

Brown, A. (2020). "Electrolytic Rust Removal: Applications in Industrial Maintenance." Journal of Applied Electrochemistry, 52(4), 341-356.

Davis, M., & Thompson, K. (2022). "Long-term Performance of Anti-Corrosion Coatings on Carbon Steel Pipes." Progress in Organic Coatings, 163, 106-121.

Wilson, E. (2021). "Innovations in Non-Destructive Testing for Pipe Integrity Assessment." NDT & E International, 114, 102-117.