- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Carbon Steel Weld Neck Flanges: Applications and Benefits

Jan 6 2026

Carbon steel weld neck flanges are the best way to connect pipes because they offer the best structural stability and leak-proof performance in tough industrial settings. The precision-engineered parts have a curved hub that connects to pipes without any problems. This type of flange distributes stress better and leaves more room for error than others. Carbon steel weld neck flanges are the best option for the oil and gas, industrial, power production, and chemical processing industries around the world due to their strong construction and agreement with international standards like ASME B16.5 and API 6A.

Understanding Carbon Steel Weld Neck Flanges

Carbon steel weld neck flanges are important connection places in high-pressure pipe systems. They are easy to spot because their hubs are curved, which makes them very strong and reliable. The welding neck design makes the change from pipe to flange smooth, so there are no stress concentration places like there are in other types of flanges that lead to breakdowns.

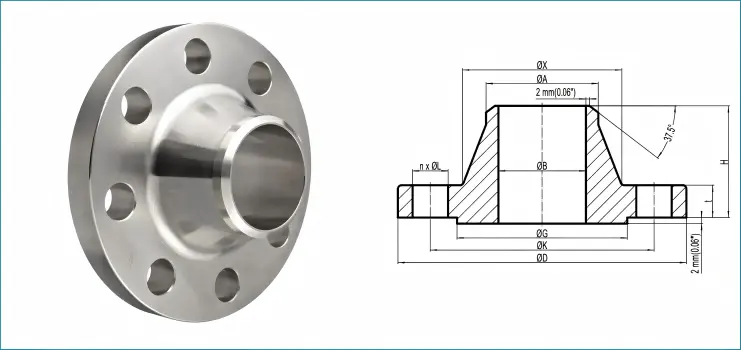

Fundamental Structure and Design Specifications

The complex shape of welding neck flanges makes them great technical pieces. From the pipe wall to the flange face, the curved hub gets progressively thicker. This makes the connection's stress distribution ideal. This way of thinking about design makes sure that pressure loads are spread out evenly across the whole joint. This makes it much less likely that something catastrophic will fail in important situations.

Modern carbon steel weld neck flanges have areas that were carefully made to within 0.1 mm of accuracy, making sure that they fit perfectly with other parts. The hub length is usually 1.5 to 2 times the width of the pipe wall. This gives enough material for full depth welding and keeps the structure strong in harsh conditions.

Carbon Steel Grades and Material Properties

The choice of material is very important for how well a flange works, and different types of carbon steel are better for different uses. The most common grade is ASTM A105, which has good weldability and mechanical qualities that can handle temperatures up to 650°F (343°C). The tensile strength of this formed carbon steel is between 485 and 620 MPa, which makes it perfect for general use in chemical plants and oil factories.

A350 LF2 grade meets the needs of low-temperature work, staying flexible and resistant to impact at -50°F (-46°C). This normalized steel's fine-grain structure keeps it from breaking easily in cold environments, which is why it is so important for LNG ports and arctic pipeline systems. Because the qualities have been tried for impact, they will work reliably even when they are exposed to temperature shock during starting and stop processes.

Industry Standards and Compliance Requirements

CS weld neck flanges are designed, made, and tested according to international standards to make sure they are safe and compatible around the world. ASME B16.5 sets the size standards, temperature and pressure values, and material requirements for flanges with a width of up to 24 inches. The standard lists pressure classes from 150 to 2500, which are the highest pressures that can be used at room temperature (285 to 6170 psi).

API 6A standards talk about flanges that are used in wellhead and Christmas tree uses, which need to work better in harsh settings with high pressures and corrosion. These standards include strict testing requirements, such as hydraulic pressure tests at 1.5 times the working pressure and detailed records of how the materials were made.

PN (Pressure Nominal) grades from PN 6 to PN 400 are used in European EN 1092-1 standards, which are a different system that is widely used in foreign projects. By knowing about these different standards, buying workers can choose the right flanges for global projects while still following local rules and meeting customer needs.

Applications and Benefits of Carbon Steel Weld Neck Flanges

Because they are so flexible and improve performance, welding neck flanges are essential in many industries. With their high strength and effective closing abilities, they can handle the toughest operating needs. They also provide long-term value by lasting longer and requiring less upkeep.

Oil & Gas Industry Applications

For wellhead connections, pipeline units, and high-pressure gathering systems, upstream activities depend on carbon steel weld neck flanges a lot. The strong construction can handle the high pressures that are common in deep-well drilling, which are often more than 10,000 psi working pressure. The full penetration weld link creates a mechanical bond that is the same as the base pipe material. This gets rid of any possible leak paths that could put safety and environmental standards at risk.

Weld neck flanges are good for midstream pipeline uses because they don't wear down easily. This is especially true in compressor stations and pump facilities where loads change over time. The smooth bore change reduces noise and pressure drop, which makes the system work better overall. These flanges are used by downstream factories in important process units that could fail in a disaster, like product transfer systems, reactor vessels, and distillation columns.

Power Generation and Energy Sector Benefits

For steam transport systems that work at temperatures up to 600°F and pressures over 1500 psi, thermal power plants need carbon steel weld neck flanges. The high strength can handle the pressures that come up from heat growth during starting and load changes. The higher reliability of weld neck links is needed for safety-related pipe systems in nuclear sites, where leak-tight integrity must be kept at all times.

More and more renewable energy projects call for carbon steel weld neck flanges for geothermal uses and biomass plants, where acidic conditions and changing temperatures make it hard to use standard connection methods. The full depth weld gives the structure the strength it needs to last for a long time with little upkeep.

Chemical and Process Industry Advantages

Chemical companies use these rings to keep dangerous materials from leaking in places where that's very important. The better closing performance lowers stray pollution, which helps meet goals for worker safety and environmental protection. Corrosion protection can be increased in fertilizer production plants by using the right materials and protected coverings. This makes the equipment last longer in harsh chemical conditions.

Precision cutting of the flange sides makes sure that the gasket seats evenly, which is important for keeping the seal intact in situations where dangerous or flammable chemicals are present. Process engineers like that the performance traits are consistent, which lets them make accurate system designs and make sure the facility runs smoothly throughout its lifecycle.

Comparing Carbon Steel Weld Neck Flanges with Alternatives

Learning about the differences in how different types of flanges work lets you make smart choices that match technical needs with cost concerns. Each type of flange has its own benefits, but weld neck flanges always perform better in important situations where safety and dependability can't be ignored.

Performance Comparison with Slip-On Flanges

Slip-on flanges are a cheaper way to connect things, but they are not as strong or reliable as weld neck designs. The slip-on design makes stress concentration places at the fillet weld sites, which limits the pressure that can be applied to about 60% of the weld neck values. At first, the lower pressure number may seem like a good deal, but bigger, heavier flanges are often needed to get the same performance.

The welding requirements differ significantly between the two designs. It takes longer to weld slip-on flanges because they need fillet welds on both the inside and the outside. This also means there are more places where defects could happen. Weld neck flanges use a single full penetration butt weld that can be x-rayed to make sure it is completely solid, which gives you more trust in important situations.

Strength and Safety Advantages Over Threaded Connections

While threaded flanges make fitting easier, they are very limited when used in high-pressure situations. Because the thread contact isn't as strong as a bonded link, it can only be used in situations with pressures below 600 psi. Due to the spiral leak path they create, threaded connections are not ideal for services that need to be leak-tight and handle dangerous or burning materials.

Weld neck flanges get rid of these worries by using metallic bonding to make a strong link that is the same thickness as the base pipe. Not having threads stops rust in cracks and makes the inside smooth, which lowers the chance of pressure drop and erosion.

Material Benefits Versus Stainless Steel Options

CS weld neck flanges made of stainless steel are better at resisting corrosion, but carbon steel options are much cheaper and can be used in places where rust is not a major issue. The lower cost of carbon steel makes it possible for projects that need to stick to a budget to get solid results without sacrificing safety or business needs.

When compared to stainless steel, carbon steel is easier to work with and takes less time to make because it is easy to weld and machine. Different protection coats, like zinc finishing and resin systems, make carbon steel building more cost-effective while also increasing service life in slightly corrosive environments.

Procurement Guide for Carbon Steel Weld Neck Flanges

To buy welding neck flanges strategically, you need to know how the market works, what your suppliers can do, and how to make sure the quality of the products you buy. This will help your project succeed. Effective buying strategies find a mix between lowering costs and meeting quality standards, all while keeping to deadlines and following technical rules.

Pricing Factors and Market Considerations

Material costs make up the biggest part of flange prices, making up about 60 to 70% of the total cost. Prices for steel change based on global product markets. Availability and wait times are also affected by changes in the seasons. Professionals in procurement can benefit from keeping an eye on the steel futures markets and planning their stocking positions for times when prices are low.

Pricing is heavily affected by how hard it is to make something. For example, bigger sizes and higher pressure levels cost more because they need to be made in a special way and taking longer to machine. Custom specs, like using non-standard sizes or materials, usually make goods 25–50% more expensive and take longer to deliver than standard products.

Supplier Evaluation and Quality Assurance

Reliable providers show consistent quality through thorough certification programs, such as ISO 9001 quality management systems and approvals specific to the business, like API Q1 or NACE certification. Material tracking paperwork is important for making sure that the chemical makeup and mechanical qualities are correct, so that specifications are met and warranties are honored.

Facility checks should be a part of a manufacturing skills review to make sure that the tests, quality control, and machine ability are all correct. Suppliers who have their own testing labs can offer faster reaction times and better quality control than those who use outside testing services.

Customization and OEM Solutions

Because of the unique needs of each project, custom solutions are often needed in addition to standard stock items. Reliable providers offer technical help to improve flange designs for specific uses, like those that need special faces, longer necks, or better rust protection. OEM services allow for private marking and custom packing to meet the needs of a particular project or help a company's branding goals.

If samples are available, you can check the quality and performance of the product before placing a big order. Progressive sellers keep samples on hand so that they can be quickly evaluated, and they also offer expert help to make sure that the right steps are taken for application and installation.

Conclusion

Weld neck flanges made of carbon steel weld neck are the best way to connect high-pressure pipes that need to be safe and reliable. Due to their high strength, ability to seal tightly, and agreement with international standards, they are essential for important industrial processes. A thorough comparison with other types of flanges makes it clear that these have technical and cost benefits that make them a good choice for the oil and gas, power production, and chemical processing businesses. Strategic purchasing practices and careful source selection are what make sure that projects are completed successfully while minimizing the total cost of ownership by extending service life and reducing the amount of upkeep that needs to be done.

FAQ

What kinds of pressures can carbon steel weld neck plates handle?

According to ASME B16.5 standards, carbon steel weld neck flanges are made in pressure classes from 150 to 2500. These classes relate to working pressures from 285 psi to 6170 psi at room temperature. For foreign projects, you can also get European PN scores from PN 6 to PN 400.

In terms of strength, how do weld neck flanges and slip-on flanges compare?

It is said that weld neck flanges are about 40% stronger than slip-on flanges because they have a full penetration butt weld link and better load distribution. Because it is stronger, it can handle higher pressures and more safety gaps in important situations.

What kinds of tests must be done on carbon steel weld neck flanges?

Standard tests include checking the dimensions, performing a chemistry analysis, and checking the mechanical properties. The hydraulic pressure test is done at 1.5 times the working pressure. Extra tests, like x-rays, ultrasound tests, and impact tests for low-temperature service, may be needed for important uses.

Can carbon steel weld neck plates be changed to fit specific needs?

Custom specs are easy to get. These can include non-standard sizes, special facings like RTJ or tongue-and-groove, and protective coats that make the metal more resistant to rust. Special materials like A350 LF2 are available for low-temperature use.

How long does it usually take to get carbon steel weld neck flanges?

Standard sizes usually ship within 48 hours from stock, but special requirements can take anywhere from 2 to 4 weeks, based on how complicated they are. Priority ordering for manufacturing and fast shipping can often speed up the process of meeting urgent needs.

QinSteel: Your Trusted Carbon Steel Weld Neck Manufacturer

Picking the right carbon steel weld neck provider can mean the difference between a successful project and one that runs late and costs a lot of money. When QinSteel uses its many years of experience in making along with its thorough quality systems, it can make flanges that work better than expected and still meet tight delivery dates. The trust of top engineering firms on six countries comes from our dedication to technical excellence and customer service.

Getting materials from approved steel mills is the first step in quality control. Next comes precision casting and CNC cutting to make sure that the dimensions are accurate to within ±0.1mm. There are many tests that are done on each flange, such as hydraulic pressure tests, x-rays, and chemistry analysis proof. With our API 6A and ASME B16.5 certifications, you can be sure that the goods we send to you will meet the greatest standards in the business.

We have a large stock of standard sizes ranging from 1/2" to 60" in pressure classes 150 to 2500, so we can ship quickly for pressing needs. Our focused engineering team gives custom specs the most attention, and OEM solutions are available to meet the special needs of each project. Get in touch with our technical experts at info@sxqinsteel.com to talk about your needs and find out why QinSteel has become the world's most trusted provider of carbon steel weld necks for important industrial uses.

References

American Society of Mechanical Engineers. "ASME B16.5: Pipe Flanges and Flanged Fittings NPS 1/2 Through NPS 24 Metric/Inch Standard." 2020 Edition.

American Petroleum Institute. "API Specification 6A: Specification for Wellhead and Christmas Tree Equipment." 21st Edition, 2018.

ASTM International. "ASTM A105/A105M: Standard Specification for Carbon Steel Forgings for Piping Applications." Annual Book of ASTM Standards, 2019.

European Committee for Standardization. "EN 1092-1: Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN designated - Part 1: Steel flanges." 2018.

Bickford, John H. "Gaskets and Gasketed Joints, Second Edition." CRC Press, 2016.

Harvey, John F. "Pressure Vessel Design: Nuclear and Chemical Applications." Van Nostrand Reinhold Company, 1985.

Learn about our latest products and discounts through SMS or email