- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Best Applications for DIN Thread Flanges

Jan 6 2026

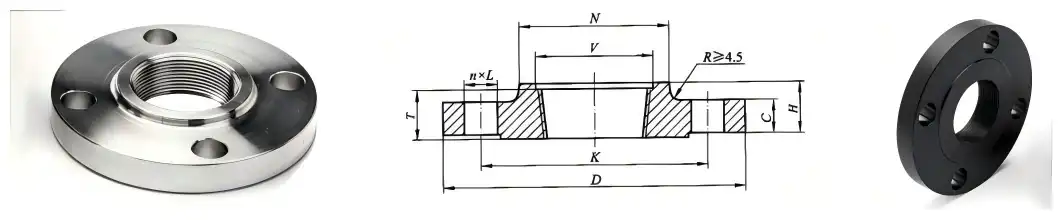

Thread flanges DIN are the very best in German engineering accuracy. They are made to meet the strict needs of current industrial uses. These threaded link parts work great in power generation systems, water treatment plants, chemical processing plants, and oil and gas pipes. The thread flange DIN standard makes sure that the dimensions are correct and that the product works reliably in a variety of working conditions. Because they are well-made and follow strict European standards, these flanges make links that don't leak and can handle high pressures and acidic conditions. This makes them essential for important building projects all over the world.

Understanding DIN Thread Flanges and Their Industry Relevance

Industrial plumbing systems that work well depend on parts that are made to strict engineering standards. DIN thread flanges are an example of German precision manufacturing. They are made according to strict rules that make sure they are the right size and work reliably in a wide range of industrial settings.

Key DIN Standards and Specifications

DIN thread flanges are made to a number of international standards, such as DIN 2576, DIN 2641, and EN 1092-1, which spell out exact limits for size and material needs. The requirements in this document make sure that the new pipeline will work with the ones that are already there, and that the construction will stay strong even under tough operating conditions. The standards cover pressure levels from CLASS 150 to CLASS 2500, so they can be used for a wide range of tasks, from low-pressure water systems to high-pressure petroleum processing.

Each thread flange DIN component is made using advanced techniques that make sure it meets the highest quality standards. To make sure the fit and seal work properly, dimension verification procedures check the thread pitch, the smoothness of the flange face, and the placement of the bolt holes. These quality controls make installation easier and lower the amount of long-term upkeep that needs to be done.

Material Excellence and Performance Characteristics

Modern DIN threaded flanges are made of high-quality materials like AISI 304/316 stainless steel, ASTM A105 carbon steel, and special alloys. Carbon steel versions are cheaper and work well for everyday tasks, while stainless steel versions are better at resisting rust in harsh chemical conditions. Specialized metals like A182 F51, F53, and F55 work better in situations with high temperatures and pressures.

Here are the main material benefits that make DIN thread flanges different:

- Resistance to Corrosion: Some types of stainless steel don't rust or react with chemicals, so they last longer in tough settings.

- Pressure Resistance: Engineered materials can handle pressures up to PN4000, making them good for high-pressure uses.

- Stability at Different Temperatures: The structure of alloys stays the same over a wide range of temperatures.

- Tensile and yield strengths that are higher than average make sure that the material will work reliably under stress.

Because of these properties of the material, DIN thread flanges work better than other options in tough operating situations. When you combine excellent metalworking skills with precise making, you get parts that work the same way for as long as they're operating.

Competitive Advantages Over Alternative Standards

When compared to ANSI, JIS, and other foreign standards, DIN thread flanges have clear advantages. German engineering puts a lot of emphasis on careful design gaps and thorough testing procedures. This makes parts that are more reliable and last longer. Specifications for thread size and binding surface shapes help squeeze the gasket and stop leaks.

The flexible design philosophy makes it easier to do upkeep and swap parts without having to make big changes to the whole system. Standard bolt designs and consistent sizes across all pressure classes make it easier to keep track of supplies and make buying things easier for repair teams.

Top Industrial Applications of DIN Thread Flanges

Because DIN thread flanges are so flexible, they can be used in many industries where efficiency and dependability are very important. These parts work great in places that need perfect closing, resistance to pressure, and chemical compatibility.

Oil and Gas Infrastructure Systems

DIN thread flanges are used for important pipeline links and machine contacts in upstream, middle, and downstream activities. The threaded design makes fitting easier in rural areas where welding might not be possible. It also keeps the pressure stability that is needed for safe movement of hydrocarbons.

These flanges are used in process pipe systems at petrochemical plants to handle flammable chemicals and high-temperature streams. The thread flange DIN guideline makes sure that it works with equipment from other countries and meets the API and ASME standards that are popular in North American setups. Traceability of materials and approval compliance help with quality assurance standards needed by government bodies.

Stainless steel DIN thread flanges are good for offshore platforms because they don't rust and are strong. Marine settings have special problems, like being exposed to saltwater and pressure loads. It is important to use high-quality materials and make sure the products are made correctly to keep everyone safe.

Chemical Processing and Manufacturing

Chemical companies need flanges that can stand up to harsh chemicals and keep their shape when heated and cooled many times. These DIN thread flanges are made from special metals that make them reliable in situations where acids, bases, and organic solvents would break down other materials.

The precise threading makes sure that the gasket is always compressed, which is very important for environmental compliance programs that want to stop rogue emissions. Accurate measurements cut down on installation time and prevent changes made in the field that could harm the system's structure.

In terms of chemistry processes, these are the exact benefits:

- Chemical Compatibility: The choice of material doesn't break down easily when exposed to process chemicals.

- Controlling emissions: precise closing surfaces keep rogue emissions to a minimum.

- Easy to maintain: threaded links make it easy to change parts quickly.

- Safety: Materials that are certified meet safety standards for the workplace

These features make DIN thread flanges very useful in industries like making fertilizer, specialty chemicals, and medicines, where protecting the environment and making sure the product is pure are very important.

Water Treatment and Municipal Infrastructure

Municipal water systems and industrial water treatment plants need flanges that are reliable for a long time and don't need much upkeep. DIN thread flanges are long-lasting and don't rust, which are important qualities for these uses. They also work well with large purchases that are common for public building projects.

Conditions in desalination plants are especially tough because of the high levels of salt and high pressures. These harsh conditions don't affect stainless steel DIN thread flanges, and they keep their shape, which is important for stable operation over long service intervals.

DIN Thread Flanges Versus Other Flange Types: Performance and Application Insights

Understanding the relative benefits of various flange types helps procurement workers make smart choices that improve performance and cut costs for certain uses.

Comparison with ANSI and International Standards

ANSI B16.5 standards are different from DIN thread flanges in a number of important ways, such as the allowed limits for size, the materials that must be used, and the ways that pressure ratings are calculated. While ANSI standards are most common in North America, DIN standards often offer more conservative design gaps that make products more reliable in tough situations.

When compared to other threading standards, DIN flanges' thread size and profile shape make the best stress distribution and closing performance. These changes to the design make it less likely that the threads will galle during assembly and make it more resistant to vibration loosening in dynamic situations.

Acceptance changes a lot from region to region. For example, European and Asian markets strongly support DIN standards, while North American projects usually require agreement with ANSI standards. Careful design management and source approval methods are often used to make sure that both standards are met in global projects.

Material Selection Strategies

Before picking between carbon steel and stainless steel DIN thread flanges, you need to carefully think about how they will be used, how much they will cost over their entire life, and how well they need to work. When rust isn't a big problem, carbon steel options are cheaper for normal uses. On the other hand, stainless steel options are worth the extra cost because they last longer and need less upkeep.

The thread flange DIN standard works with different types of materials, so it can be optimized for different working conditions. Alloy steels that are better at resisting creep are good for high-temperature uses, while materials that stay flexible at low temperatures are needed for cold uses.

Total ownership costs, such as installation, upkeep, and repair costs over the lifetime of a component, must be taken into account in a cost-effectiveness study. Even though they cost more at first, high-quality materials often offer better value because they need less upkeep and last longer between services.

Design Considerations and Selection Criteria

Threaded flanges work great in situations where parts need to be taken apart often for repair or inspection. The mechanical link gets rid of the heat-affected areas that come with soldered parts and is strong enough for mild pressure uses.

How well a seal works depends on which gasket is used and how it is installed. DIN thread flanges have precise closing surfaces that can fit a range of gasket materials, such as elastomers, compressed fiber, and metal designs, to suit different service conditions.

Procurement Considerations for DIN Thread Flanges in B2B Markets

To successfully buy DIN thread flanges, you need to carefully evaluate suppliers, check the quality of their products, and optimize the supply chain to make sure that parts are always available and work consistently.

Supplier Selection and Quality Assurance

To find approved providers, you have to look at their manufacturing skills, how well they follow approval rules, and how well they handle quality. Manufacturers that have been around for a while and have ISO 9001 certification and industry-specific approvals can be more sure that their products will be consistent and that they can provide expert support.

Protocols for quality assurance should include checking the licensing of materials, checking their dimensions, and performing tests that are in line with the project requirements. Third-party testing services can make sure that the product meets DIN standards and customer needs without any bias.

Diversified buying strategies that balance lowering costs with reducing risk are good for the robustness of the supply chain. Regional sellers may be faster at delivering goods and offer better technical help, but global buying may be cheaper for big orders.

Bulk Ordering and Customization Options

Through direct connections with manufacturers and combining orders, volume buying methods can save a lot of money. When you buy in bulk, you can also make changes, like using different materials, sizes that aren't standard, or marking needs that are unique to your business.

To get the best lead time, project plans and production capacity need to be carefully coordinated. Standard thread flange DIN setups usually have faster delivery times than special standards, which need dedicated production runs.

Here are the most important benefits of strategic sources for procurement:

- Lowering costs: purchasing in bulk and working directly with manufacturers lower unit costs

- Consistency in quality: companies that have been around for a while offer solid quality and expert support

- Delivery Optimization: Placing goods strategically cuts down on project delays

- Customization Options: OEM relationships make it possible to meet unique needs

With these buying benefits, project teams can get the best results in terms of both cost and scheduling while still meeting the quality standards that are necessary for practical success.

QinSteel: Your Trusted Partner for Premium DIN Thread Flanges

With 20 years of experience, QinSteel has been making and selling high-quality thread flange DIN parts to industry markets around the world. We can provide solutions that meet the most demanding needs in the oil and gas, chemical processing, power production, and water treatment industries because we have a deep knowledge of foreign standards and customer needs.

Manufacturing Excellence and Quality Commitment

Our factory is GMP-certified and uses strict quality control procedures to make sure that every thread flange DIN part meets or goes beyond international standards. With the help of skilled workers and advanced production tools, the quality of the surface finish and precision of the dimensions ensure consistent performance in the field.

Premium types from approved sources are emphasized when sourcing materials, and full tracking paperwork is provided to meet customer quality assurance standards. Before the product is shipped, it is put through a series of thorough tests that check its mechanical properties, chemical makeup, and physical compliance. This makes sure that the quality of the product stays the same, which builds long-term customer trust.

Quality management includes more than just making things. It also includes transportation, customer service, and packing. Protective packaging keeps things from getting damaged during shipping, and clear paperwork makes the receiving inspection and installation processes easier.

Comprehensive Product Range and Customization Services

With pressure values ranging from CLASS 150 to CLASS 2500, our product line includes thread flange DIN standards from 1/2" to 24" in diameter. You can use carbon steel grades A105 and A350 LF2, stainless steel types 304 and 316, and special alloys made for harsh situations.

Because we can customize, we can meet the specific needs of each customer, such as non-standard sizes, special materials, and custom labels. OEM and ODM services help engineering contractors and companies that make equipment that needs custom solutions for certain uses.

Sample services make it easier for customers to evaluate and qualify products, so they can be thoroughly tested and approved before committing to large amounts of production. Technical help during the design and selection process makes sure that the product is perfectly matched to the needs of the application.

Global Distribution and Customer Support

Strategic warehouse sites in North America, Europe, and Asia make it easy to meet customer needs quickly while keeping shipping times and transportation costs to a minimum. Management of inventory strikes a balance between cost-effectiveness and availability, making sure that there are enough items in stock to meet typical needs while also allowing for custom orders.

Customer support includes everything from the first question to technology help after delivery. Application tech support helps customers choose the best options, and fast contact makes sure that questions and concerns are answered quickly during the buying process.

Conclusion

For tough industry uses, thread flange DIN options offer the best mix of speed, dependability, and cost-effectiveness. Because they are made with great care and follow strict German standards, they are perfect for oil and gas infrastructure, chemical processing plants, power generation systems, and water treatment plants. Because the materials and pressure levels are so flexible, they can be changed to fit specific operating needs while still being compatible with foreign pipe standards. To do buying right, you need to carefully evaluate suppliers, check their quality, and use smart sourcing methods that get the best results for both cost and performance for long-term business success.

FAQs

Which materials work best in places where they can rust?

Grades 316 and 316L of stainless steel are very good at resisting rust in chemical handling and naval uses. Other metals, like F53 and F55, can handle being exposed to very strong chemicals. To get the best results, when choosing materials, you should think about certain chemicals, temperature ranges, and concentration levels.

What makes DIN thread flanges different from ANSI ones?

When compared to ANSI standards, DIN thread flanges usually have more conservative design gaps and tighter measurement limits. Both standards provide solid performance, but DIN flanges tend to last longer in difficult situations. However, area tastes and project requirements play a role in the choice.

How long does it usually take to get custom orders in bulk?

Standard configurations can be shipped within 7–15 days from inventory, while unique designs can take up to 3–6 weeks, based on the supply of materials and the difficulty of the making process. For sales with a lot of items, focused production schedule can help find the best shipping time for each project.

What kinds of pressure rates are most often given?

Most industrial uses fall into the CLASS 150 and CLASS 300 categories. High-pressure systems in oil and gas activities use CLASS 600 and higher categories. When choosing a pressure number, you should think about both the working pressure and the safety factors that are needed by the rules and standards that apply.

Connect with QinSteel for Expert Thread Flange DIN Solutions

QinSteel can meet all of your industrial pipe needs with high-quality thread flange DIN goods that are made to strict standards. Customers from all over the world believe our expert team's full application support, low prices, and reliable delivery, which is why they have won their trust. Whether you need standard setups from our large inventory or unique solutions for specific uses, we offer the quality and service that keeps your operations going smoothly. Email our team at info@sxqinsteel.comto talk about your needs and find out why top companies choose QinSteel as their thread flange DIN provider of choice.

References

Bickford, John H. "Gaskets and Gasketed Joints: Design and Application Guidelines." Marcel Dekker Engineering Press, 2018.

Deutsche Institut für Normung. "DIN 2641: Threaded Steel Pipe Flanges - Technical Specifications and Dimensional Standards." Berlin Technical Publications, 2019.

Henderson, Robert K. "Industrial Piping Systems: Design, Installation, and Maintenance Best Practices." McGraw-Hill Professional Engineering, 2020.

International Association of Pipeline Engineers. "Flange Selection and Application Guide for Industrial Process Systems." Pipeline Engineering Journal, 2021.

Mueller, Stefan and Weber, Klaus. "European Flange Standards: Comparative Analysis of DIN, EN, and International Specifications." European Industrial Standards Review, 2020.

Smith, David L. "Materials Engineering for Industrial Flanges: Metallurgy, Testing, and Performance Optimization." Industrial Materials Science Quarterly, 2019.

Learn about our latest products and discounts through SMS or email