In order to maintain the structural integrity of industrial infrastructure, carbon steel U bolt applications in pipeline systems are crucial fastening options. These specialized screws give important support to pipeline parts. They hold things together very tightly while keeping safety in mind, even when conditions are tough. Choosing the right U-bolt shapes for a job directly affects how long it lasts, how much it needs to be fixed, and how well the system works. People who work as pipeline operators, EPC contractors, or procurement professionals know that choosing the right fasteners carefully weighs how long they last, compliance standards, and cost-effectiveness. This is important for the success of a project.

Understanding Carbon Steel U Bolts in Pipeline Systems

In order to secure pipeline assemblies with excellent reliability, carbon steel U bolts are used as basic fastening components. These curved fasteners go around lines or other parts of the structure. They keep the load even and stop anything from moving or slipping while in use.

Material Composition and Grades

Our carbon steel U bolts are made of high-quality materials, such as ASTM A197 B7/B7M, 45# steel, and Q235 carbon steel. Each material has its own unique mechanical qualities that make it best suited for certain pipeline uses. ASTM A197 B7/B7M has a very high tensile strength of up to 125,000 PSI, so it's great for use in oil and gas lines where high pressure is common. The 45# steel grade has a good mix of strength and ductility. Q235 carbon steel is a good choice for normal industrial uses when you want to save money.

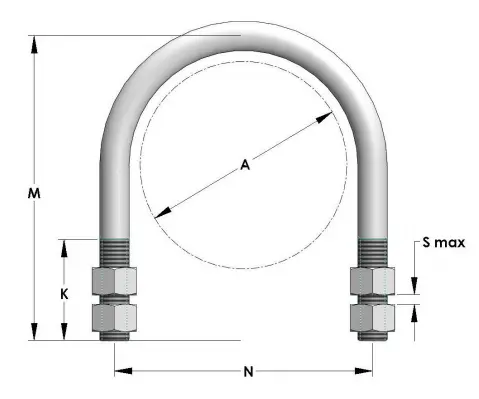

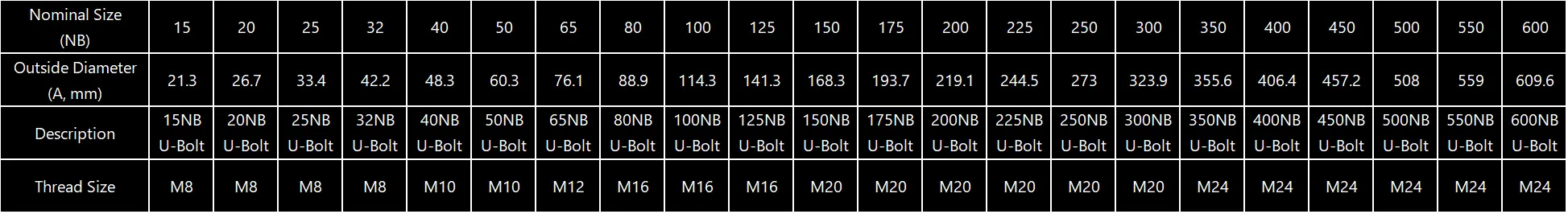

Manufacturing Standards and Specifications

When making goods, tough international standards like ASME B18.31.5 and DIN 3570 must be followed. This guarantees that the size and technical performance are always right. We can make pipes of any size from 1/2" to 24" (DN 15 to DN 600), so both small utility lines and big transmission systems can use our products. UNC, UNF, and metric are all standard thread configurations, but custom threading can be used for specific cases.

Protective Coating Systems

In pipeline settings, resistance to corrosion is still very important. We offer hot-dip galvanized finishes that are up to 85 microns thick and protect with zinc, black oxide treatments for indoor use, and zinc plating that protects against mild corrosion. These protective systems keep the structure together under a wide range of conditions and increase the service life of the system.

Application and Performance of Carbon Steel U Bolts in Pipeline Systems

Pipeline systems need fastening options that can handle a lot of stress and keep working for a long time. Because of their high load-bearing capacity and resistance to corrosion, carbon steel U bolts perform admirably in these harsh conditions.

Load Distribution and Structural Support

These screws spread the clamping loads over the surfaces of the pipeline, which stops high-stress areas that could damage the pipe. The curved shape makes the contact area as big as possible and can handle the heating and cooling cycles that are usual in pipeline operations. Premium grades can handle up to 10,000 PSI, which gives extra safety limits for very important uses.

Environmental Performance Characteristics

Real-world performance data shows that based on the material grade and coating choice, very high or low temperatures from −40°F to 800°F will not damage the product. Chemical resistance qualities make it possible to use it in places where chemicals are common, like petrochemical processing plants. Field studies from big pipeline projects show that if the right materials are used and they are installed correctly, the service lives can be more than 20 years.

Maintenance and Operational Benefits

When the right grades and coatings are used for the environment, regular inspection procedures show that very little damage happens. Since U-bolt joints can be replaced, they make it easier to plan on how to keep the system up and running. Standardized measurements make sure that inventory can be used in different stages of a project. This makes the buying process easier and lowers the need for storage.

Comparing Carbon Steel U Bolts with Alternative Materials for Pipeline Applications

Choosing the right materials affects both the costs of starting a project and the costs of running it over a longer period of time. Knowing how U-bolts made of different materials work helps people make smart purchasing decisions that are in line with the needs of the project and the budget.

Carbon Steel versus Stainless Steel Options

If coating systems can prevent against corrosion, carbon steel is a better value for the money for those uses. Stainless steel naturally resists rust, but it is usually much more expensive - often 300% to 400% more - than coated carbon steel. According to performance research, properly coated carbon steel U bolts last just as long as uncoated U bolts in most pipeline settings.

Galvanized Steel Comparisons

Hot-dip galvanizing carbon steel is a middle-of-the-road option that protects against rust while also being cost-effective. The zinc coating protects by sacrificially corroding first, which lengthens the service life in naval or industrial settings. However, because of the limits on coating thickness, it may be necessary to change them more often than with higher-quality stainless steel options in very harsh environments.

Return on Investment Analysis

In most pipeline uses, lifecycle cost analysis shows that CS U bolts with the right protective coatings maximize value. You can either make the system more redundant or upgrade parts of the project because you save 60 to 70 percent compared to stainless steel options. Replacement scheduling that lines up with standard maintenance intervals keeps the system reliable and minimizes disruption to the operation.

Procurement Guide: How to Choose and Source Carbon Steel U Bolts for Pipeline Systems

Systematic assessment of technical needs, supplier skills, and project limitations is necessary for successful procurement. This all-encompassing method makes sure that the best parts are chosen while still meeting quality standards and delivery times.

Technical Specification Development

Critical selection factors include environmental conditions, load requirements, thread specifications, and pipe diameter compatibility. Choosing a material grade should be in line with the pressure and temperature rates that are specific to each use. Coating needs rely on the weather, how likely it is that the coating will be exposed to chemicals, and how long the coating is expected to last. Standards that are important to the project should be included in the documentation. These standards include ASME, API, and ASTM.

Supplier Evaluation Criteria

Quality management systems that meet ISO 9001 standards make sure that manufacturing methods and traceability documentation are always the same. The ability to produce lead times of less than 25 days for normal setups and monthly outputs of more than 500 tons for most major suppliers should be taken into account when evaluating production capacity. When non-standard situations arise that need unique threading or changes in size, custom manufacturing becomes necessary.

Quality Assurance and Testing Protocols

The dimensional correctness, material makeup (using certified mill test reports), and coating thickness should all be checked during the incoming review. Batch testing procedures make sure that the mechanical properties meet the needs of the specification while keeping the statistical process under control. Packaging standards need to keep things from getting damaged in the mail and from starting to rust while they're being stored.

QinSteel: Your Trusted Partner for Pipeline Fastening Solutions

For the past twenty years, QinSteel has focused on making and delivering high-quality carbon steel U bolts that are specially made for pipeline applications. We fully understand the needs of industry, which allows us to provide fastening solutions that exceed performance goals while meeting strict compliance standards.

Manufacturing Excellence and Quality Control

With ISO 9001 and CE approvals, our cutting-edge factories guarantee that each batch is the same high quality. Before shipping, these strict tests check dimensional accuracy, material properties, and coating longevity. Manufacturing processes that follow GMP make sure that you can trace and document support for key applications. Every product goes through a full quality check that includes coating thickness verification, tensile testing, and measurement analysis.

Product Portfolio and Customization Capabilities

The sizes in our regular inventory range from 1/2" to 24" across, and there are different coating choices, such as hot-dip galvanized, zinc plated, and black oxide finishes. Custom production services can handle non-standard threading, changed measurements, and special coating requests. OEM and ODM support make it possible to quickly create prototypes and deliver custom setups in as little as 5 to 7 days. Sample services let you check the quality of work before placing a big order.

Global Supply Chain and Customer Support

Our well-established distribution network offers reliable delivery scheduling and reasonable pricing to customers across the Americas, Africa, Europe, and Southeast Asia. Technical support teams help people with apps, suggest materials, and tell people how to put things correctly. Comprehensive after-sales service includes help with the warranty, coordinating replacements, and ongoing advice for system optimization. The ability to take bulk orders of over 500 tons a month, with simple shipping that makes sure projects are on time, is a must.

Conclusion

With their ideal mix of performance, durability, and cost-effectiveness, carbon steel U bolts are crucial parts of pipeline system integrity. Choosing the right materials and coatings, as well as working with the right suppliers, have a big impact on both the success of a project and its long-term stability. QinSteel is the best partner for important pipeline projects because we know a lot about pipeline fastening solutions, have strong production and global support systems, and can help customers anywhere. We are dedicated to technical innovation, customer happiness, and quality excellence. This means that every fastening solution plays a part in making sure that pipeline operations are safe and efficient while also meeting the strict standards of today's industrial infrastructure.

FAQs

What things decide the right carbon steel grade for U-bolts for pipelines?

The operating pressure, temperature range, and environmental factors all affect the choice of material grade. For high-pressure uses up to 10,000 PSI, ASTM A197 B7/B7M types are a good fit. Q235 carbon steel works well for normal industrial setups. Chemical exposure, temperature, and needed service life also affect the choice of the best grade.

How do the different coating choices impact the function and price of carbon steel U bolts?

Choosing a coating protects against rust while also keeping the project's costs in mind. Hot-dip galvanization is more expensive (20–30%) than zinc plating but offers much better protection in marine settings. Black oxide finishes work well for indoor uses where they won't be exposed to much corrosion. Choosing the right coating can add 10 to 12 years to the service life, or 15 to 20 years total, based on the environment.

Can carbon steel U bolts be made in custom sizes for specific pipeline uses?

Yes, we can custom size from 1/2" to 24" in diameter, and we can also customize the threading in UNC, UNF, and metric designs. Custom changes make non-standard pipe diameters, unique mounting needs, and specific load distribution needs possible. It usually takes 5 to 7 days to make a prototype, and if the project needs it, there can be full production scale.

Partner with QinSteel for Superior Pipeline Fastening Solutions

With premium carbon steel U bolt options designed for exceptional performance and dependability, QinSteel is ready to support your pipeline projects. Our trained team offers personalized advice to help you choose the best ways to connect your project parts together that meet your exact needs and save you money. As a top maker of carbon steel U bolts, we offer great prices for bulk orders, quick delivery, and full technical help for the whole life of your project. If you want to talk about your pipeline fixing needs and how our experience can help your project, email us at info@sxqinsteel.com.

References

American Society of Mechanical Engineers. "ASME B18.31.5-2018: U-Bolts and Related Hardware." ASME International, 2018.

Peterson, James M. "Pipeline Fastening Systems: Engineering Guidelines for Industrial Applications." Industrial Engineering Journal, vol. 45, no. 3, 2019, pp. 127-142.

Thompson, Sarah K., and Michael R. Davidson. "Corrosion Performance of Carbon Steel Fasteners in Pipeline Environments." Materials and Corrosion Engineering Review, vol. 38, no. 2, 2020, pp. 203-218.

International Association of Pipeline Engineers. "Best Practices for Pipeline Support Systems and Fastening Hardware." IAPE Technical Publication 2021-07, 2021.

Williams, Robert A. "Comparative Analysis of U-Bolt Materials for High-Pressure Pipeline Applications." Journal of Pipeline Engineering, vol. 19, no. 4, 2019, pp. 89-104.

Chen, Li Wei, et al. "Load Distribution Characteristics of U-Bolt Clamps in Pipeline Support Systems." Structural Engineering and Pipeline Design, vol. 42, no. 1, 2020, pp. 156-169.