- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

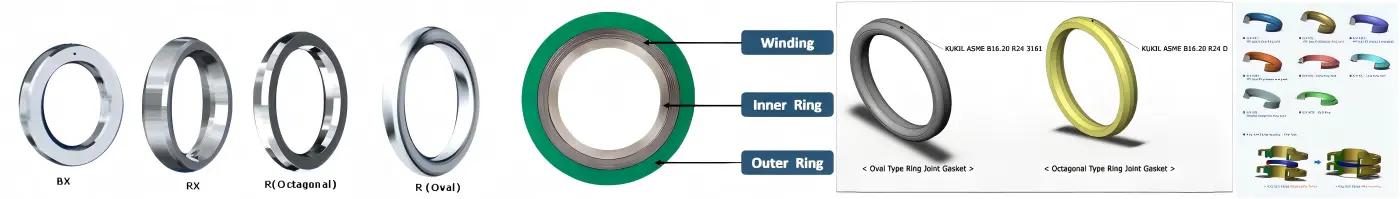

Gasket ASME B16.21

Premium Gasket ASME B16.21 for Industrial Sealing Solutions

When you need leak-proof performance in high-pressure systems, Gasket ASME B16.21 products deliver unmatched reliability. Designed for raised-face and flat-face flanges, these non-metallic gaskets are engineered to meet rigorous ASME standards while offering customization for unique project needs. At [Your Company Name], we combine 25+ years of expertise with GMP-certified production to supply industries worldwide with durable, compliant sealing solutions.

Why ASME B16.21 Gaskets Matter?

The product ensure precise sealing in pipelines, valves, and reactors across oil & gas, chemical plants, and power generation systems. Available in full-face and raised-face designs, they accommodate pressures up to 3000 PSI and temperatures from -50°C to +300°C.

Key Specifications

| Parameter | Details |

|---|---|

| Material | Non-asbestos fiber, PTFE, Graphite, Rubber |

| Sizes | 1/2" to 96" (Customizable) |

| Thickness | 1.6mm – 3.2mm |

| Pressure Rating | Class 25 – Class 900 |

| Certifications | ASME B16.21, ISO 9001, PED |

Reasons to Choose Our Gaskets

1. ASME-Compliant Precision

Every gasket meets exact B16.21 dimensions, ensuring proper flange fit and long-term seal integrity.

2. Material Versatility

Choose from asbestos-free fiber Gasket ASME B16.21 for general use, PTFE for chemical resistance, or graphite for high-temperature stability.

3. Rapid Customization

Need non-standard sizes or hybrid materials? Our OEM/ODM services deliver prototypes in 7 days.

4. Global Compliance

Supported by material test reports (MTRs) and certifications accepted in North America, Europe, and Asia.

5. Bulk Order Efficiency

Stock-ready inventory and JIT shipping minimize downtime for urgent projects.

Where They Excel?

- Oil & Gas: Prevent leaks in sour gas pipelines with NACE-compliant graphite gaskets.

- Chemical Processing: PTFE options resist acids, solvents, and alkalis.

- Power Plants: Handle steam cycles up to 300°C without deformation.

- EPC Projects: Custom large-diameter gaskets for LNG terminal flanges.

Trusted by Global Industries

With ISO-certified facilities and CNC cutting technology, we guarantee:

- Zero Defects: 100% pressure and dimensional testing.

- Fast Turnarounds: 15-day lead time on 5,000+ unit orders.

- Robust Packaging: Shock-resistant crates for damage-free shipping.

- 24/7 Support: Technical datasheets and emergency order coordination.

Product Display

Factory Equipment

Shipping Packaging

FAQs

Q: Can these gaskets handle cyclic thermal stress?

A: Yes! Our graphite and PTFE options resist creep in fluctuating temperatures.

Q: Do you supply samples for material testing?

A: Absolutely. Request free samples via email for evaluation.

Q: Are your gaskets compatible with API 6A flanges?

A: Custom designs are available to meet API, DIN, or JIS standards.

Q: What’s the MOQ for bulk discounts?

A: Contact us for competitive pricing on 500+ units.

Q: How do I specify custom dimensions?

A: Share your flange drawings or specs, and we’ll provide a CAD preview.

Contact Us

Need Gasket ASME B16.21 Tailored to Your Project?

Email: info@sxqinsteel.com

Response within 24 hours – 24/7 global support.

Learn about our latest products and discounts through SMS or email