- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Ring Joint Face Flanges

Premium Ring Joint Face Flanges for High-Pressure Sealing Solutions

Xi 'An QinSteel Trading Co., Ltd is a trusted manufacturer and global supplier of precision-engineered Ring Joint Face Flanges designed for critical applications in oil, gas, and petrochemical industries. Our flanges meet ASME B16.5, API 6A, and EN 1092-1 standards, ensuring leak-proof performance in extreme-pressure environments. With GMP-certified production and a large inventory, we deliver reliable solutions tailored to your project needs.

Product Overview

The products (RTJ Flanges) feature precision-machined grooves that create a metal-to-metal seal using oval or octagonal gaskets. Ideal for pipelines, wellheads, and compression stations, these flanges excel in high-temperature and high-pressure conditions up to 2500lb. Available in Welding Neck, Slip-On, Blind, and Threaded types, they support sizes from ½" to 60" (DN15–DN1500) in ASTM A105, stainless steel, and alloy materials.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN 10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN 15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Material Excellence

- ASTM A105 Carbon Steel: Optimal for general high-pressure systems.

- A182 F304/F316 Stainless Steel: Resists corrosion in acidic or marine environments.

- A350 LF2: Built for subzero temperatures (-46°C).

Why Our Ring Joint Face Flanges Stand Out?

✅ Global Compliance: ASME, API, ISO, and PED certifications for universal acceptance.

✅ Sour Service Ready: NACE MR0175-certified options for H2S-rich environments.

✅ Custom Solutions: OEM/ODM support for non-standard sizes/groove profiles.

✅ Rapid Delivery: 30%+ pre-machined stock for urgent orders.

Applications

- Offshore drilling rigs and subsea pipelines.

- Refinery manifolds and gas compression units.

- High-pressure steam lines and chemical processing.

Why Choose QinSteel?

- GMP-Certified Facilities: Zero-defect production with full material traceability.

- Global Warehouses: Fast shipping from hubs in Houston, Dubai, and Rotterdam.

- 24/7 Engineering Support: Assistance with installation and leak testing.

Quality Assurance

Every Ring Joint Face Flanges undergoes:

✔️ 100% dimensional inspection (ASME B16.20).

✔️ Ultrasonic Testing (UT) and Magnetic Particle Inspection (MPI).

✔️ Pressure testing up to 1.5x rated capacity.

Packaging & Logistics

Triple-layer anti-corrosion packaging with wooden crates ensures safe delivery worldwide.

Quality Control

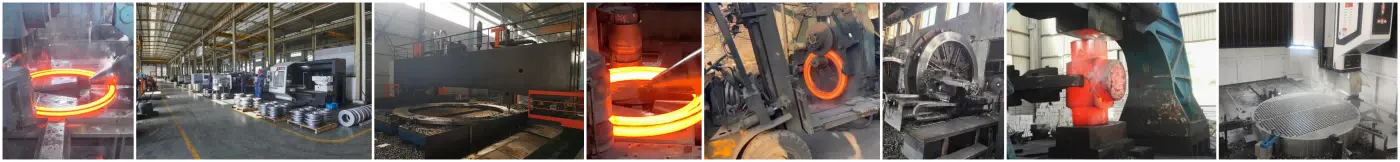

Factory Equipment

Shipping Packaging

FAQ

Q: Can you provide API 6A-compliant flanges for offshore projects?

A: Yes, our RTJ flanges meet API 6A standards for subsea applications.

Q: Do you offer NACE-certified materials?

A: Absolutely. We supply duplex/super duplex steel flanges for sour service.

Q: What's the lead time for custom sizes?

A: Standard orders ship in 2–4 weeks. Expedited options available.

Q: Are mill test reports included?

A: Yes, each shipment includes digital MTCs with heat treatment records.

Contact Us

Email: info@sxqinsteel.com

Share your flange specifications for Ring Joint Face Flanges for instant pricing and lead time!

Learn about our latest products and discounts through SMS or email