In-house lab testing for A350 LF2 Pipe Flanges sour service environments reduces validation time by 66% vs. third-party providers.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

A350 LF2 Pipe Flanges

Xi 'An QinSteel Trading Co., Ltd – Premier Manufacturer of ASTM A350 LF2 Pipe Flanges

ASME/API-Certified Low-Temperature Flanges | Bulk Stock Available | 15-30 Day Global Delivery

Engineered for Extreme Conditions: A350 LF2 Pipe Flanges

When you need flanges that withstand sub-zero temperatures and high-pressure environments, A350 LF2 Pipe Flanges deliver unmatched performance. Manufactured under strict ASME B16.5 and API 6A standards, our carbon steel flanges excel in oil and gas pipelines, LNG terminals, and offshore platforms where -45°C/-50°F toughness is non-negotiable. With 20,000+ units in stock and PED/EN 1092-1 compliance, we ensure rapid project deployment without compromising material integrity.

Material Specifications

| STANDARD | TYPE | SIZE | PRESSURE |

| ASME B16.5 | WN, SO, SW, BLD, THREADED, LP | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| ASME B16.36 | WN, SO, THREADED | 1/2" ~ 24" | CLASS 300LB ~ 2500 |

| ASME B16.47 | WN BLD | 26" ~ 60" | CLASS 75 ~ 900 |

| ASME B16.48 | SPECTACLE BLANKS, SPADES, RING SPACERS | 1/2" ~ 24" | CLASS 150 ~ 2500 |

| AWWA C207 | STEEL RING, BLD, STEEL HUB | 4" ~ 96" | 86 ~ 275 PSI |

| API 6A | WN, BLD, THREADED, INTEGRAL, TEST | 2-1/16" ~ 20-3/4" | 13.8 MPa ~ 138.0 MPa |

| API 605 | WN | 26" ~ 60" | CLASS 150 ~ 900 |

| SANS 1123 | WN, PLATE, SCREWED, SO, LOOSE, BLANK, INTEGRAL | DN10 ~ 3600 | 250 ~ 4000 kPa |

| AS 2129 | BLD, PLATE, BOSS, WN | DN15 ~ 1800 | TABLE A ~ TABLE T |

| BS 3293 | SO, WN | 26" ~ 48" | CLASS 150 ~ 600 |

| BS 4504 | PLATE, LOOSE, BLANK, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 4000 | PN 6 ~ 40 |

| EN 1092-1 | PLATE, LOOSE, BLIND, WN, SO, THREADED, WO PLATE, INTEGRAL | DN 10 ~ 3600 | PN 6 ~ 400 |

| JIS B2220 | SOP, SOH, SW, WN, LJ, TR, IT, BL | DN 10 ~ 1500 | 5 ~ 63 K |

| MSS SP-44 | BLD, WN | 12" ~ 60" | CLASS 150,19.6bar ~ CLASS 900, 153.1 bar |

Why A350 LF2 Stands Out?

- Material Grade: ASTM A350 LF2 forged steel with 0.30% max carbon content for optimal weldability.

- Certifications: API 6A, ASME B16.5, PED 2014/68/EU, and ISO 9001:2015.

- Surface Options: RTJ, RF, FF facings; epoxy/grease coatings available.

5 Reasons to Partner With Us

1. Project-Ready Inventory

20,000+ A350 LF2 flanges (DN50-DN400) in Dubai, Houston, and Bremen hubs for 7-day regional delivery.

2. NACE MR0175 Compliance

3. Bulk Order Savings

Save 10-15% on 1,000+ unit orders through raw material bulk procurement.

4. Full Material Traceability

EN 10204 3.1/3.2 certificates and mill test reports provided with every shipment.

5. Customization Expertise

Modify bore sizes, bolt circles, and coatings to match your piping schematics.

Critical Applications

- High-pressure gas transmission lines (API 6A compliant)

- Cryogenic LNG storage tank connections

- Subsea pipeline repair kits with PTFE-coated flanges

Rigorous Quality Assurance

Every A350 LF2 flange undergoes:

✅ Ultrasonic Testing (UT) for weld integrity

✅ Magnetic Particle Inspection (MPI) for surface cracks

✅ Hardness testing per ASTM A370

Global Logistics Made Simple

- Packaging: VCI-coated wooden crates with edge guards.

- Shipping: DDP/DAP incoterms supported; real-time tracking via 24/7 portal.

Quality Control

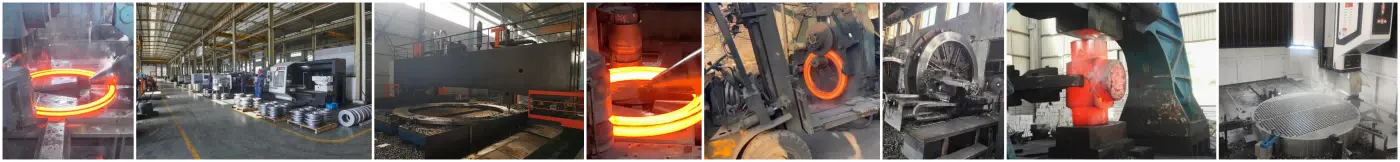

Factory Equipment

Shipping Packaging

FAQ: A350 LF2 Pipe Flanges

Q: Can you meet NACE MR0175 for sour gas projects?

A: Yes – Our in-house heat treatment ensures compliance without delaying your timeline.

Q: What's the MOQ for custom flanges?

A: 50 units for modified designs; no MOQ for stock items.

Q: How do you handle certification for EU projects?

A: All flanges include PED 2014/68/EU Declaration of Conformity and EN 10204 paperwork.

Q: Do you supply matching gaskets/bolts?

A: Yes – Ask about our pre-assembled flange kits for faster installations.

Contact Us

Need A350 LF2 Pipe Flanges with Full Documentation?

Email: info@sxqinsteel.com

Serving Oil & Gas Distributors in 12 Countries Since 2009

Learn about our latest products and discounts through SMS or email